Japan, Orientalmotor

Orientalmotor AR Series αSTEP

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: AR Series

Hybrid control provides easier use and more reliable control

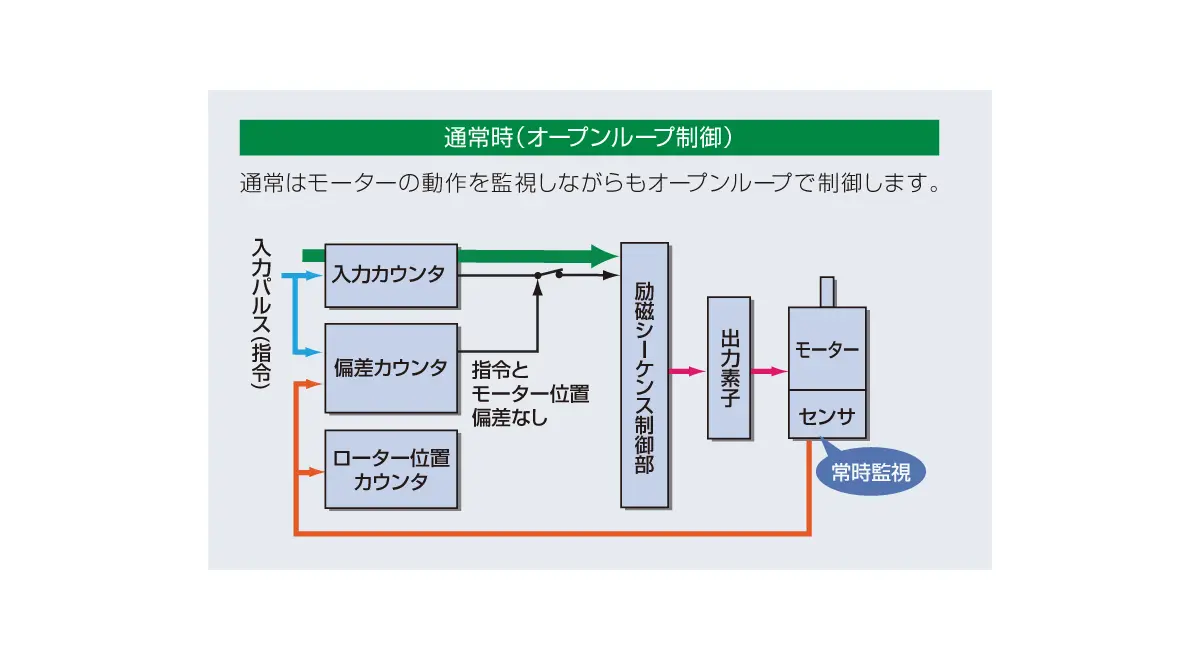

αSTEP is a stepping motor-based motor that uses a unique hybrid control method that combines the advantages of “open loop control” and “closed loop control.” It constantly monitors the motor’s position and automatically switches between the two types of control depending on the situation.

Under normal conditions, open loop control makes it as easy to use as a stepping motor

High Response

Taking advantage of the high response of stepping motors, it can move short distances in a short time. It can move following commands without delay.

Holds stop position without hunting

Since the motor stops at position using its own holding force without hunting, it is ideal for applications where vibration when stopping with a low rigidity mechanism is unacceptable.

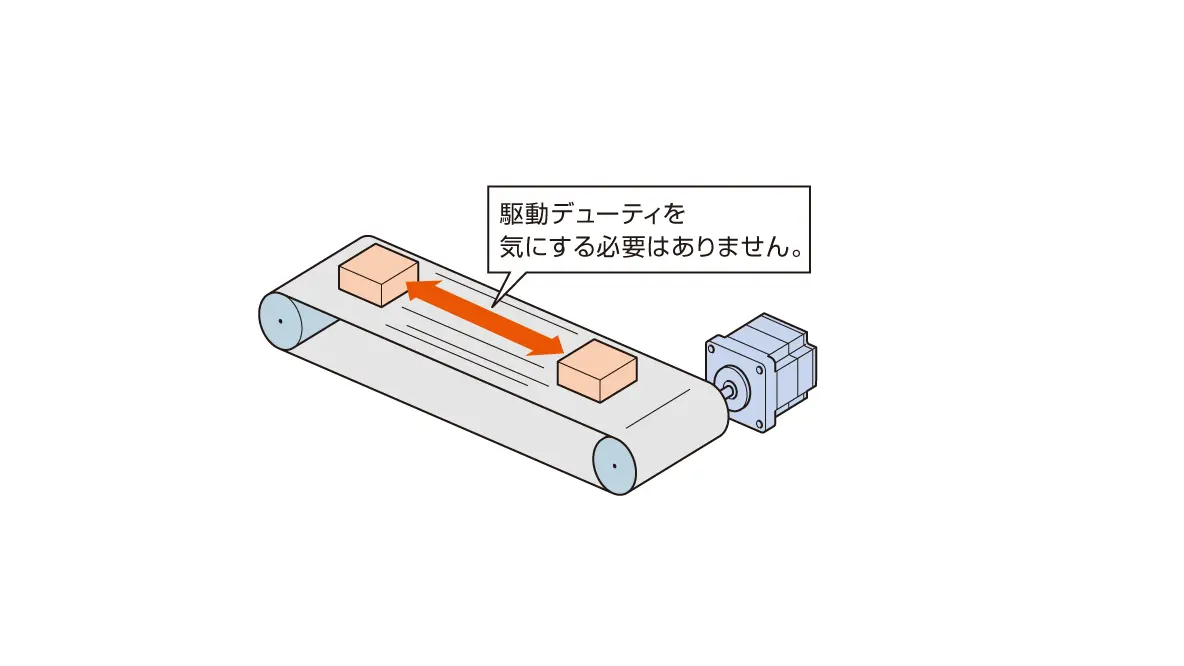

No Tuning Required

Since it normally operates under open loop control, positioning is possible without gain adjustment even when there are load fluctuations such as belt mechanisms, cams, and chain drives.

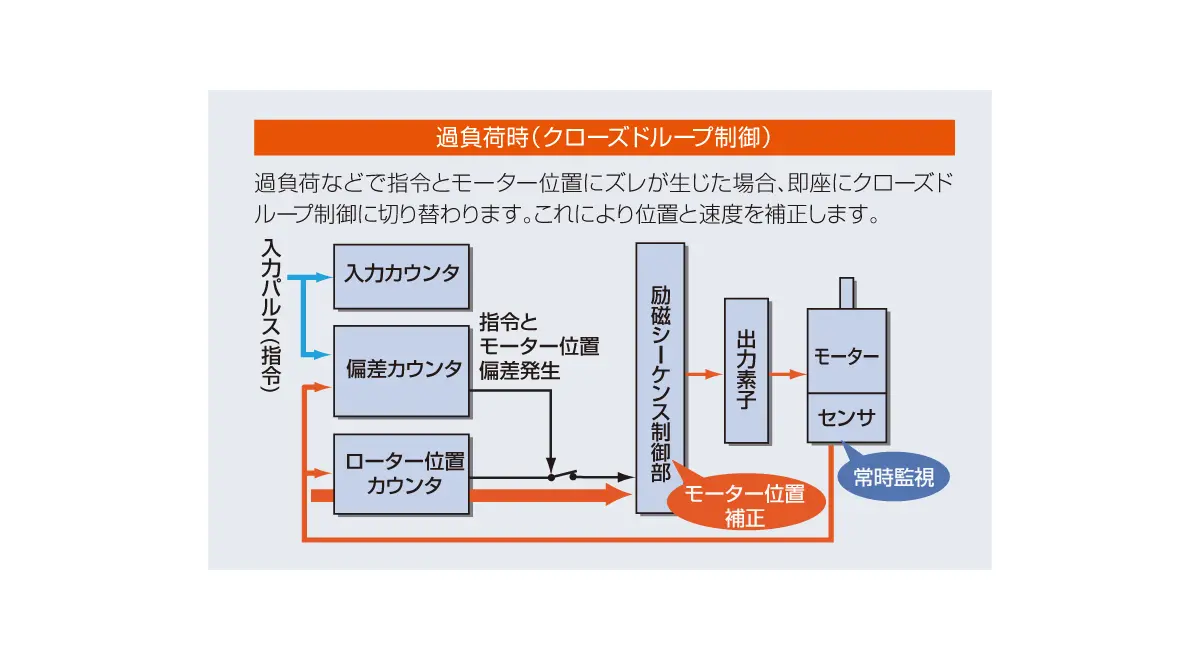

Closed loop control for more reliable operation during overload

Continues operation even with sudden load changes and rapid acceleration

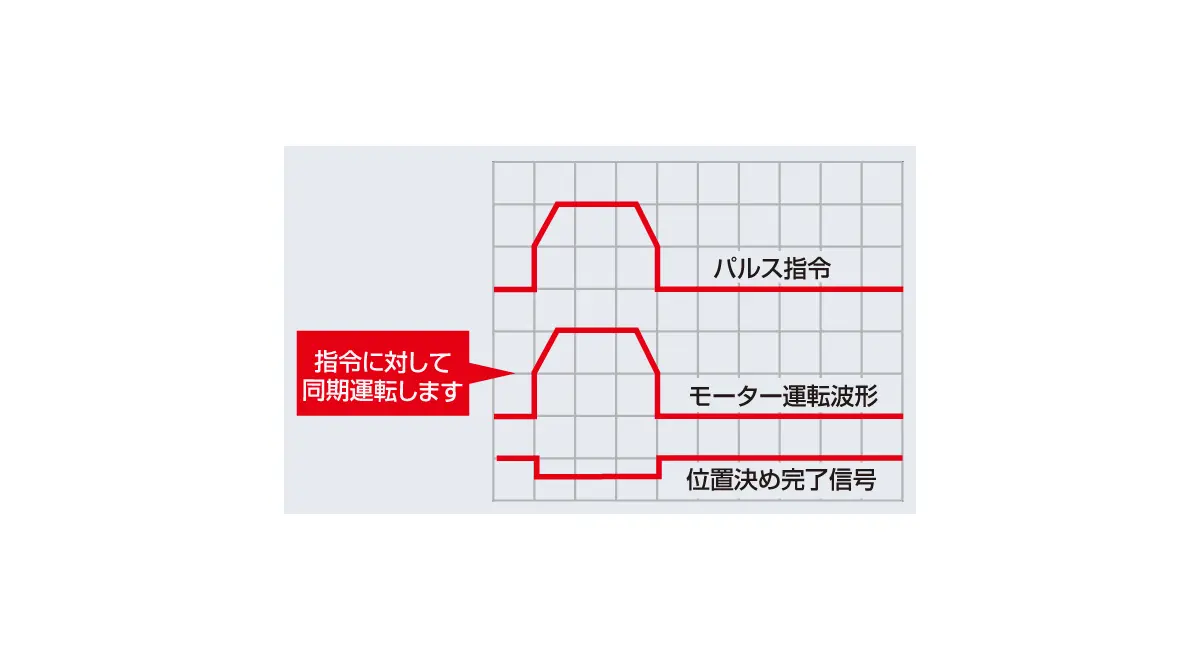

Under normal circumstances, it operates in open loop control in sync with commands. In the event of an overload, it immediately switches to closed loop control and compensates for the position.

In the unlikely event of an abnormality, an alarm signal is output.

If a continuous overload is applied, an alarm signal is output, and when positioning is complete, an END signal is output, providing the same reliability as a servo motor.

Smooth movement even at low speeds

The standard micro-step drive and smooth drive functions * reduce vibration at low speeds, allowing for smooth movement.

- * This control automatically drives in microsteps at the same movement distance and speed as in full step without changing the pulse input settings.

High efficiency reduces heat generation from the motor and enables continuous operation

Technical Report RENGA

This is technical content that introduces useful technical information and our efforts in product development. We

will explain low iron loss technology for stepping motors.

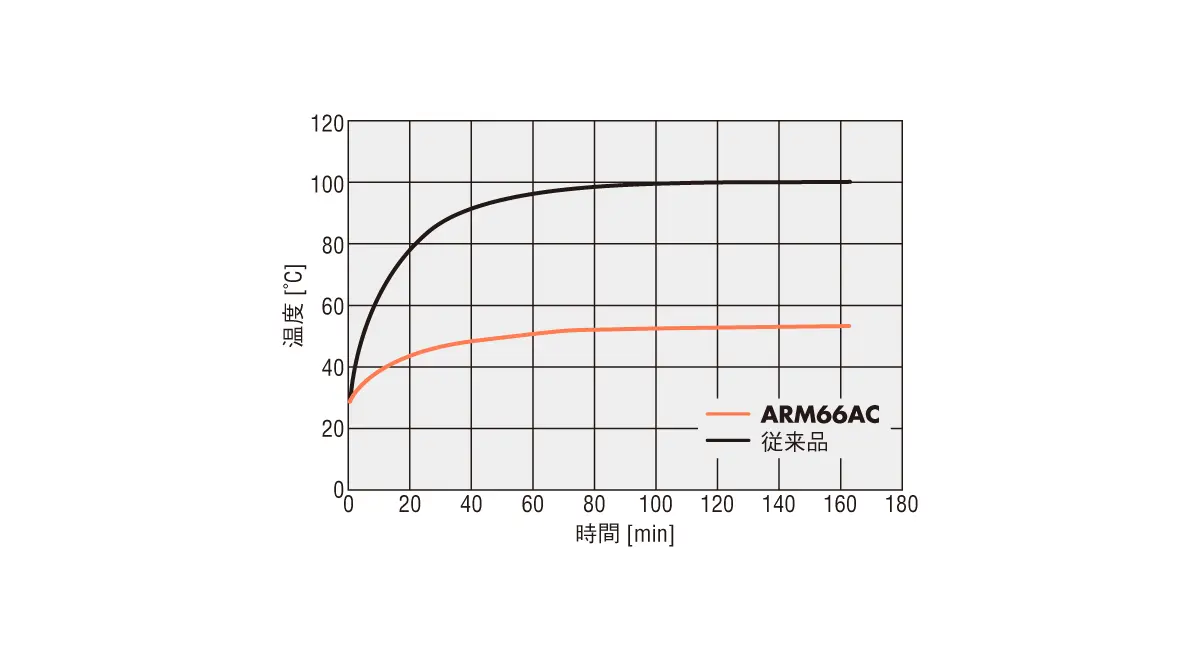

Greatly reduces heat generation

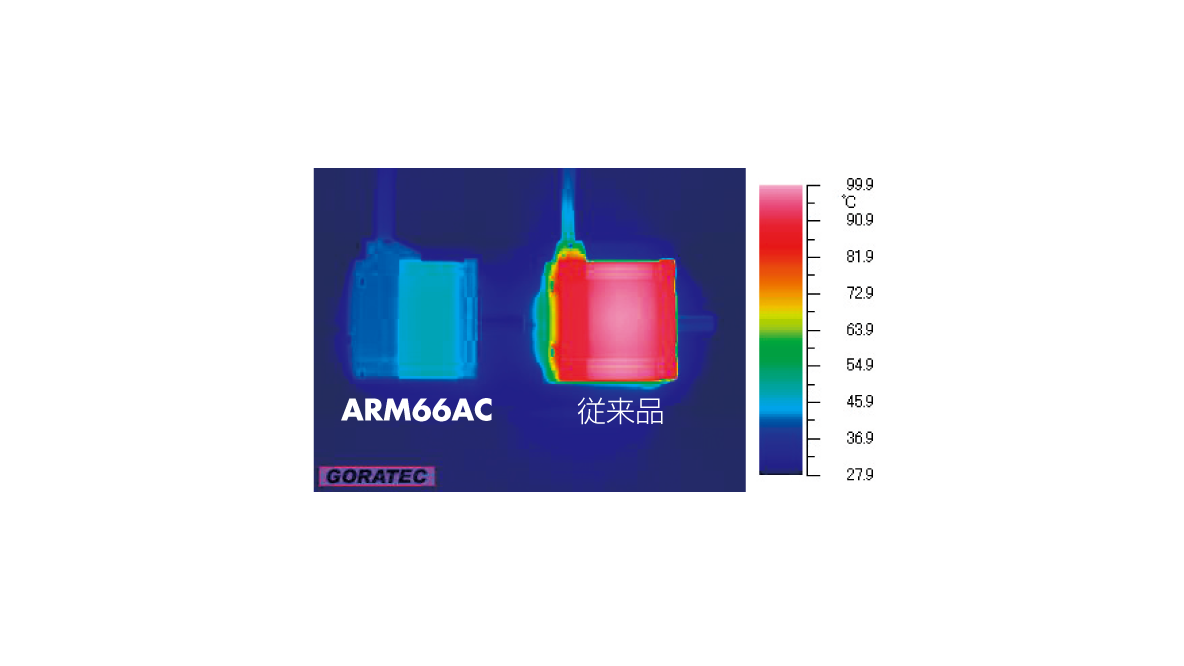

Temperature distribution by thermography

Motor housing temperature when operating under the same conditions

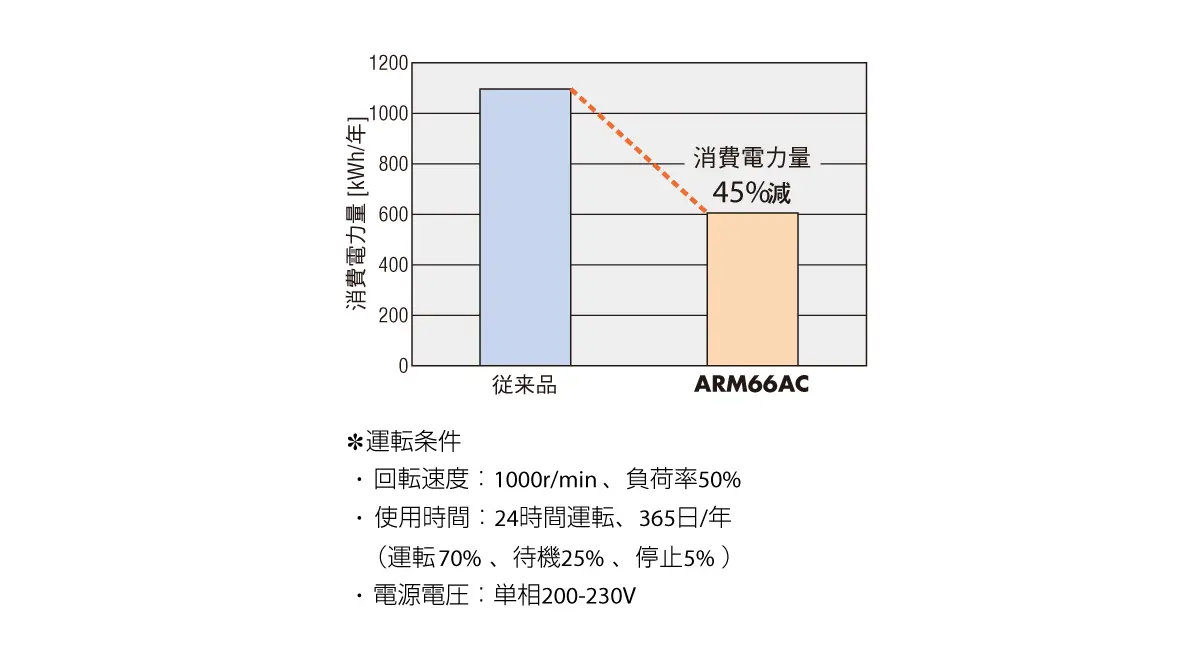

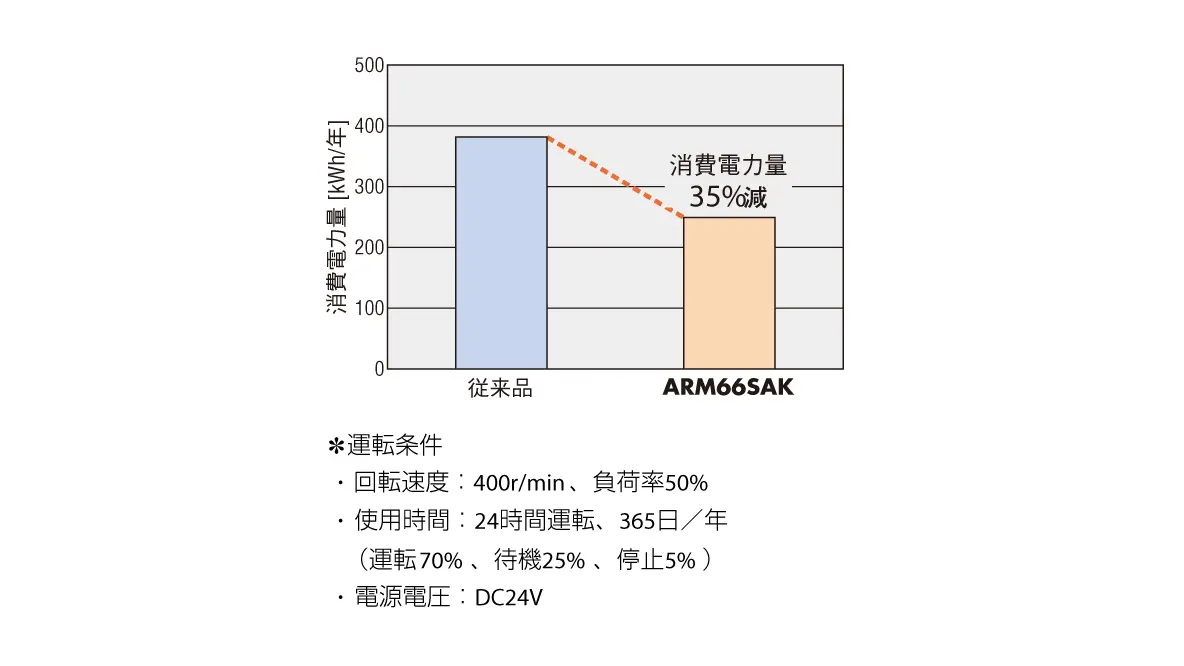

Energy saving reduces power consumption

AC power in

Power consumption: 45% less than previous model (compared to our previous model)

DC power in

Power consumption: 35% less than previous model (compared to our previous model)

Continuous operation (high frequency operation)

High frequency operation is possible. The motor can be driven continuously.

Please note

For continuous operation, a heat sink equivalent to the aluminum plate of the following size is required.

- AC power input: 250 x 250 mm, thickness 6 mm

- DC power input: 100 x 100 mm, thickness 6 mm

Equipped with rotor position detection sensor (resolver)

The rotor position detection sensor detects rotor position information by utilizing the change in inductance caused by changes in the spatial distance between the sensor rotor teeth and the stator teeth.

Stepping motor output guideline (AC power input only)

The output (W) of a servo motor is expressed as the output (W) when it is rotating at the “rated rotation speed.”

On the other hand, stepping motors, which are characterized by high-precision positioning and high torque in the mid-to-low speed range, do not have a “rated rotation speed,” so there is no indication of a “rated output.”

For reference, the following page lists the rated torque of a servo motor equivalent to the wattage of an AR series motor.

Pursuing ease of start-up, control and maintenance

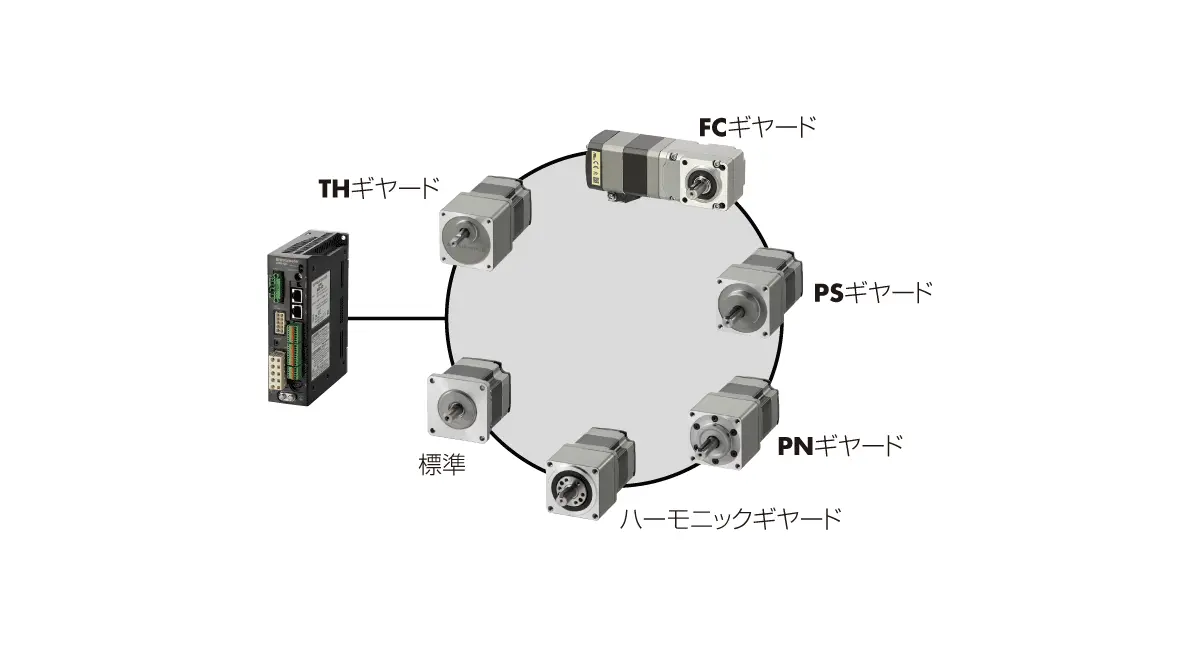

One driver can handle a variety of motors

A single driver can be connected to a variety of motors, from standard types to geared types. Since there is no need to change the driver model for each motor to be combined, maintenance is simplified. The driver also has an automatic recognition function that distinguishes the type of motor connected.

The rotor position detection sensor detects rotor position information by utilizing the change in inductance caused by changes in the spatial distance between the sensor rotor teeth and the stator teeth.

Easy to operate and full functionality

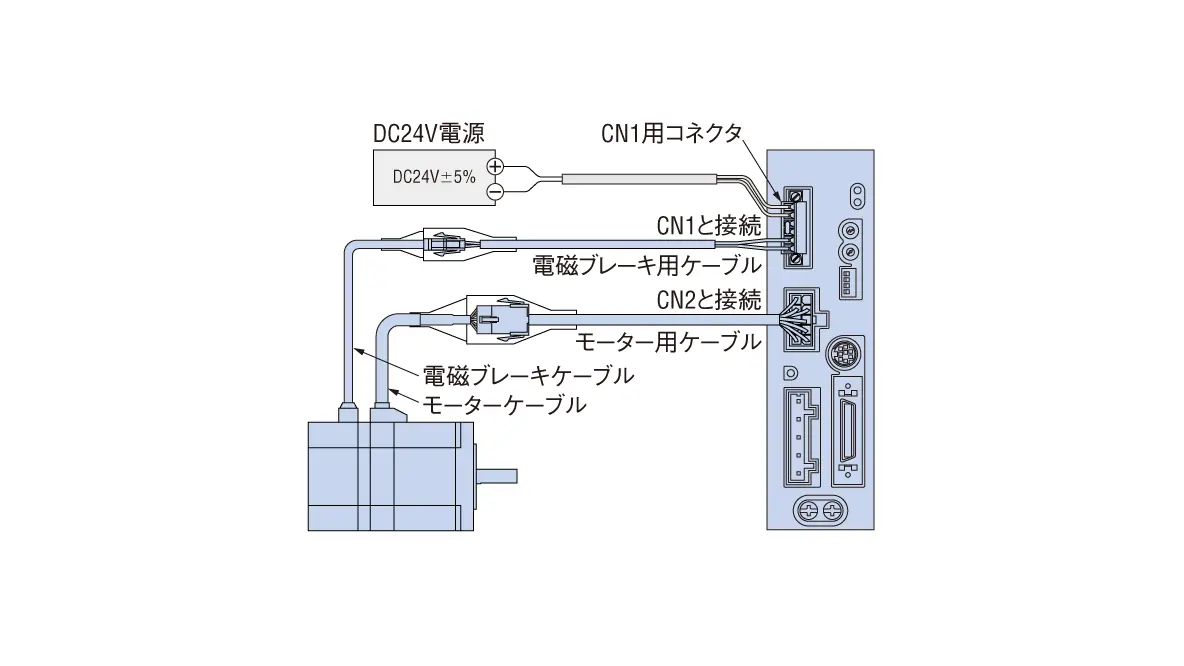

Automatic electromagnetic brake control (excluding DC power input and pulse train input types)

When the motor is excited (current-on input ON), the electromagnetic brake is released, and when the excitation is cut (current-on input OFF), the electromagnetic brake is applied to hold the motor in position.There is no need to prepare a brake control circuit.

Please note

The AC power input pulse train input type requires a separate 24V DC power supply for electromagnetic brake control.

Separate main power supply and control power supply

In addition to the main power supply, a terminal for inputting a control power supply is provided. Even if the main power supply is cut off due to an emergency stop, etc., if 24V DC is applied to the control power supply input terminal, position detection and alarm confirmation are possible. In the case of the pulse train input type, it can be operated with only the main power supply.

The maximum extension distance between the motor and the driver is 30m.

You can extend the cable length up to 30m by using a connection cable. Relay cables and movable cables are also available.

Push operation

The load is continuously pressurized. When the load is contacted, the device enters a pushing operation state, allowing pressure to be applied at a constant torque.

Please note

- To perform push-motion operation, the data input unit OPX-2A (sold separately) or support software MEXE02 is required.

- Do not perform pushing operation on geared types, as this may damage the motor or gears.

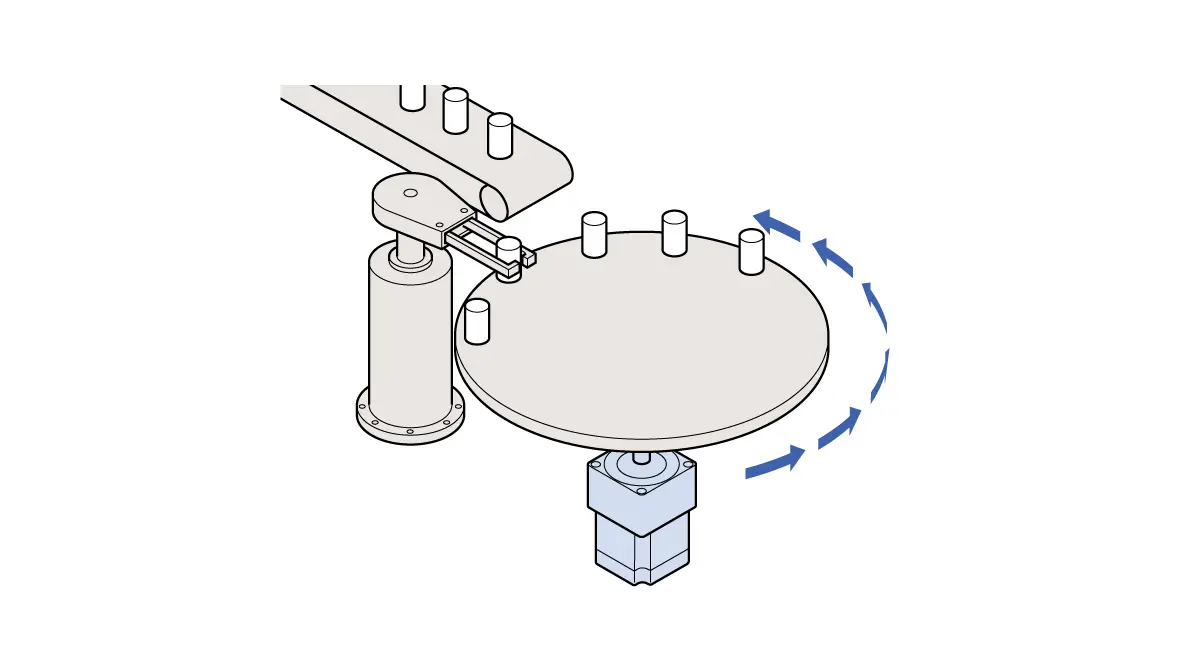

Position management in the same direction

The round function enables position management even in applications where positioning in the same direction is repeated.

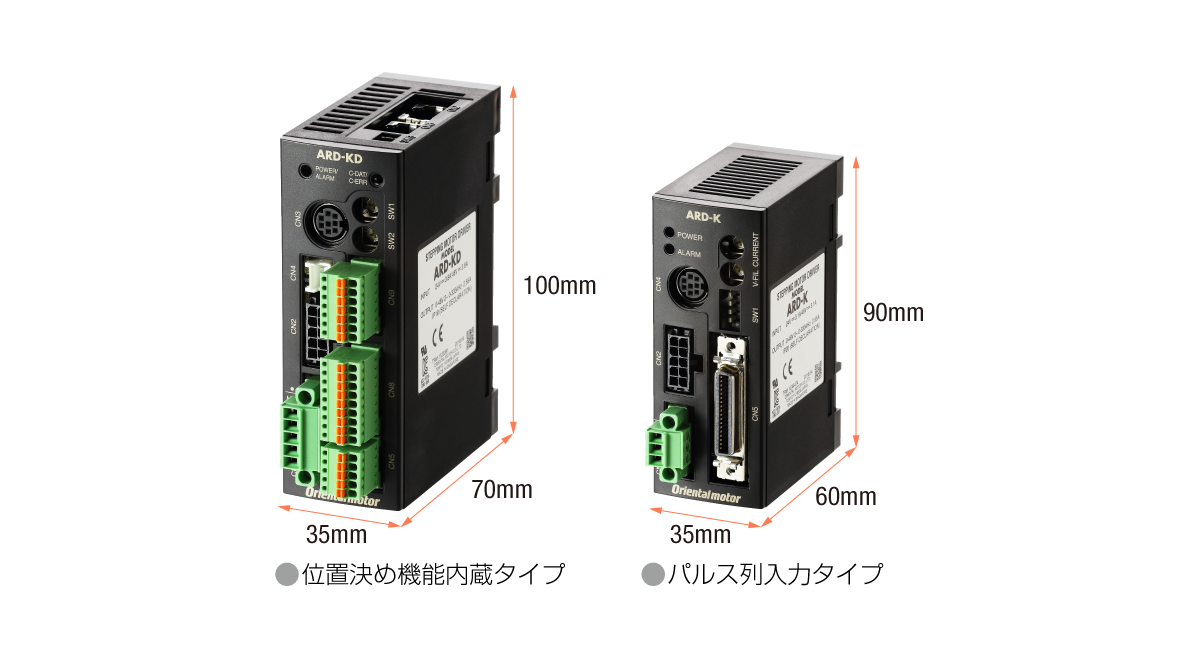

Compact small driver (DC power input only)

This contributes to space saving in control panels and equipment. It can be directly mounted on a DIN rail.

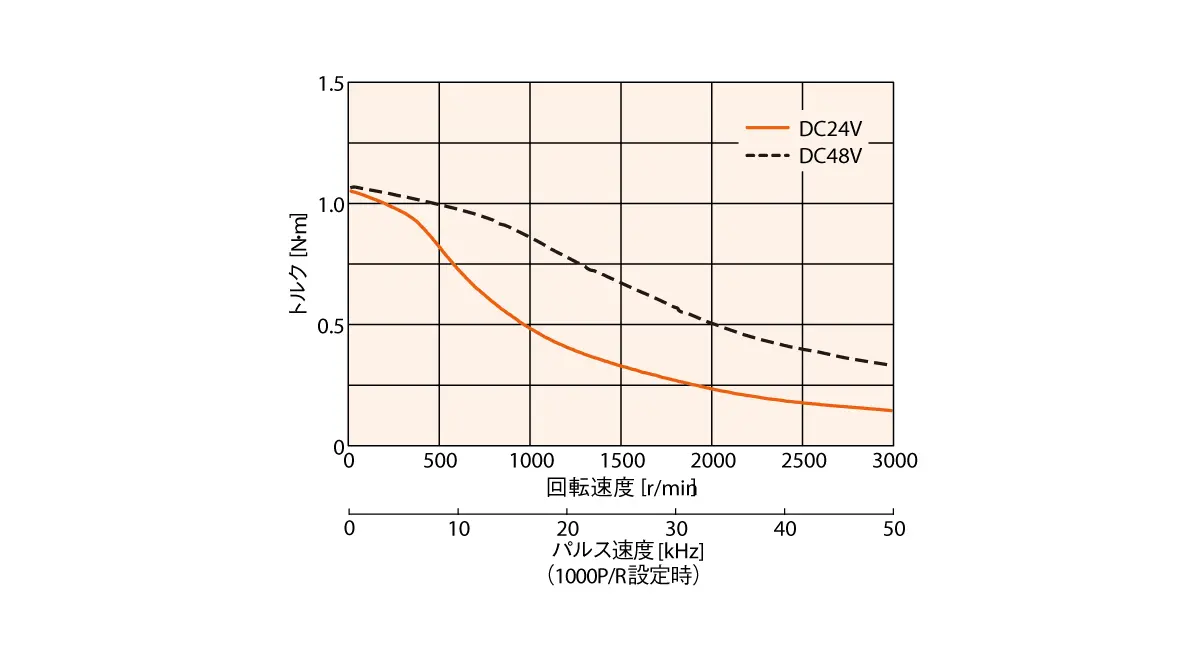

Supports DC48V

The power supply specifications are DC24V or DC48V. When used with DC48V, the torque is increased compared to DC24V. (Mounting dimensions 20mm and 28mm are only compatible with DC24V input.)

Easier to use with improved stepping motor characteristics

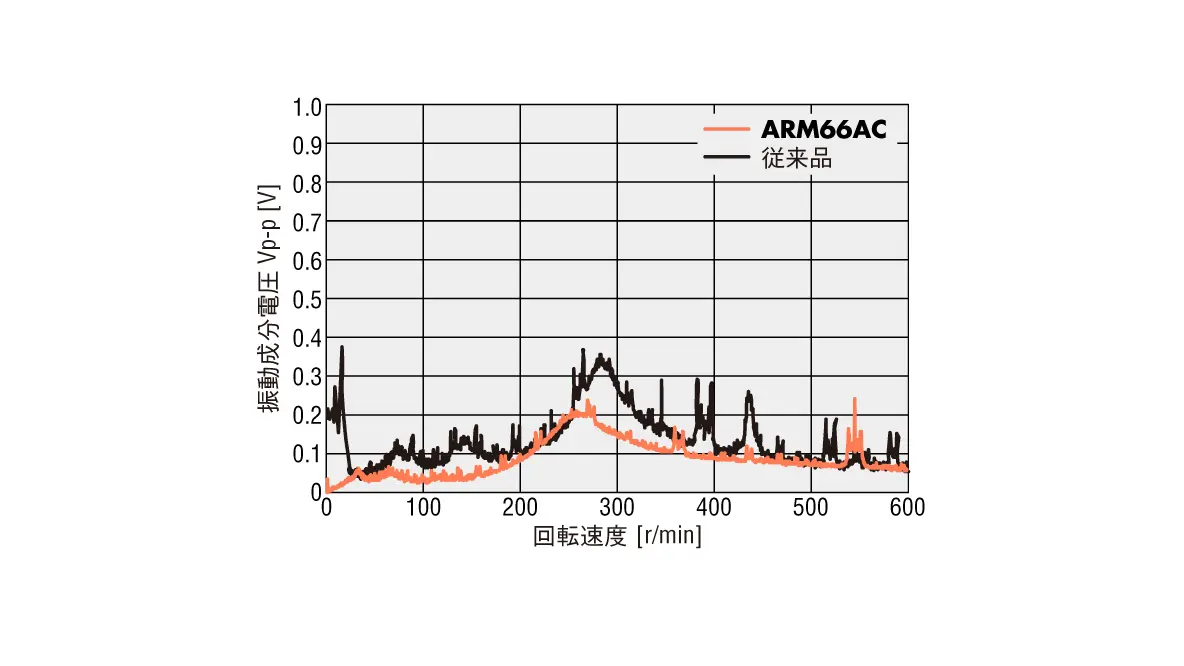

Low vibration

In addition to the micro-step drive method, the smooth drive function has been added, making operation even smoother. Even without changing the pulse input settings, micro-step drive is automatically performed at the same movement amount and speed as in full step.

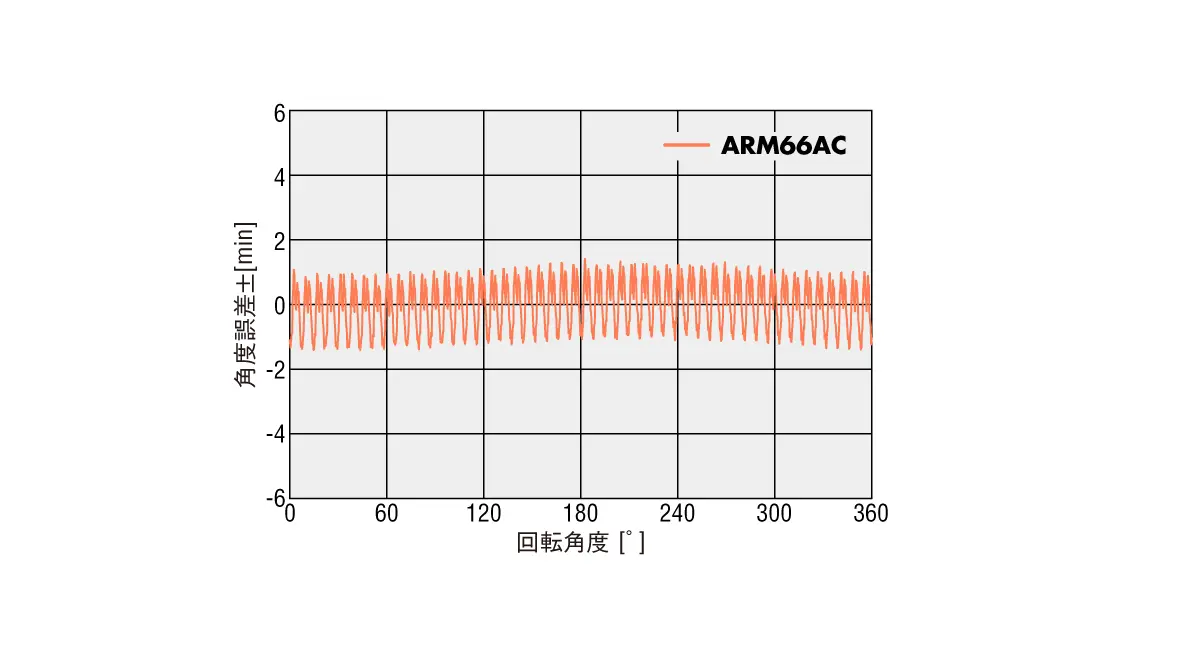

Improved angle accuracy

Improvements in current control technology have improved the motor’s static angle error, enabling more precise positioning.

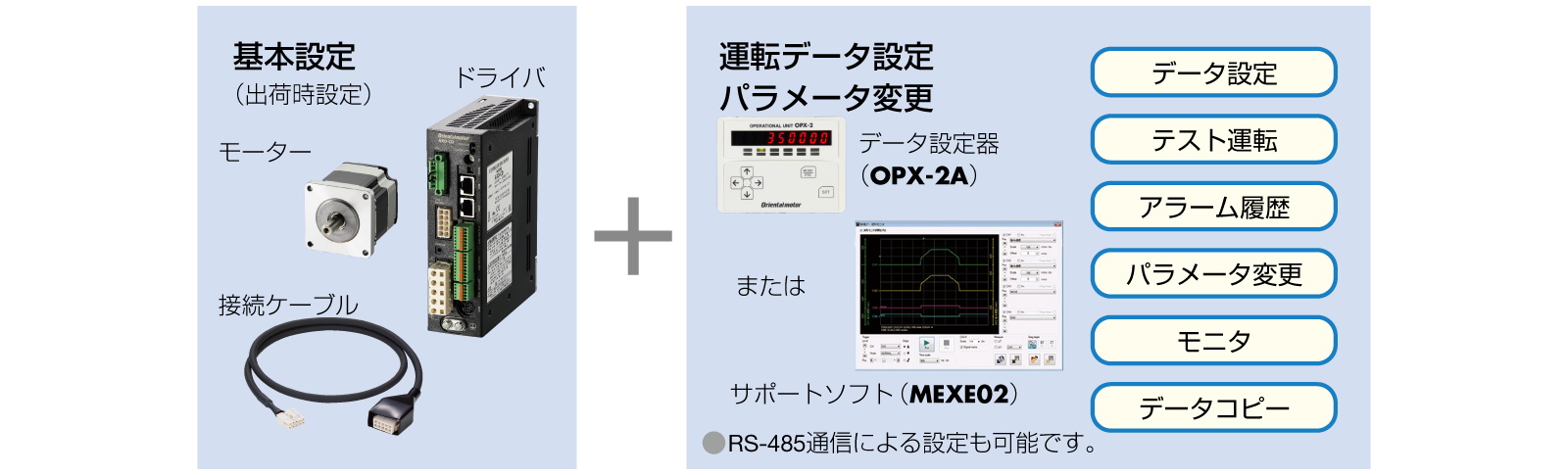

Easy to set up and operate

The support software MEXE02 is software that supports everything from start-up to maintenance. It allows you to set and edit operation data and various parameters on a computer, as well as teach and monitor various conditions.

Waveform Monitor

It has a full range of monitor functions that allow you to grasp the motor operating status and I/O status.

Supports various standards and equipment design (AC power input only)

Protection rating: IP65 *

The motor’s protection rating is IP65 * . It prevents dust from entering and hindering normal operation. (*Excluding the motor mounting surface and connector. Double shaft products are IP20.)

Compliant with semiconductor manufacturing equipment standard “SEMI F47”

This product complies with the power supply voltage drop standard in the SEMI standard. It can be considered for use in semiconductor manufacturing equipment. However, please be sure to evaluate it with the actual equipment.

Compliant with international safety standards

It has obtained UL/CSA standard certification and carries CE marking (Low Voltage Directive, EMC Directive).

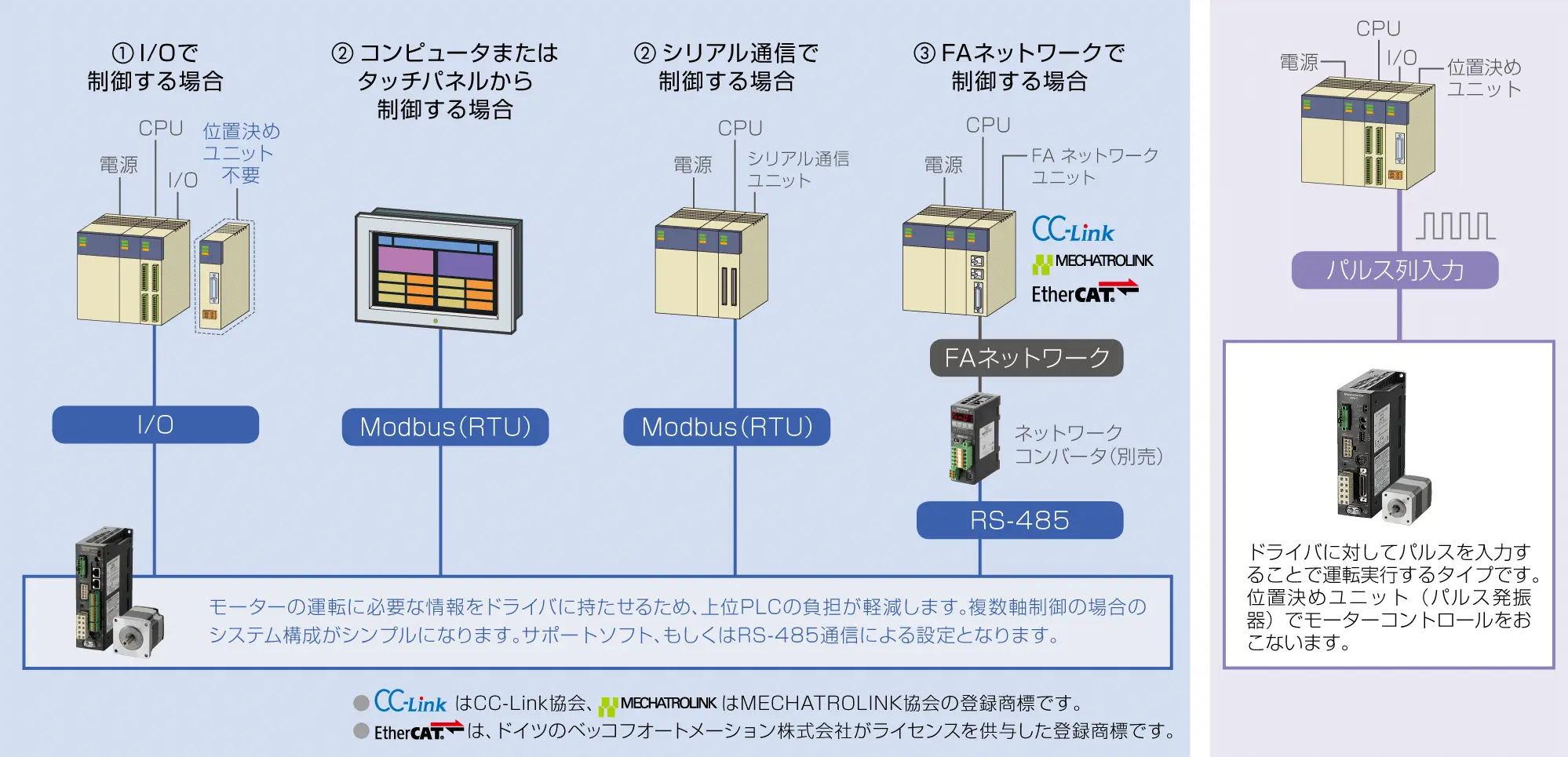

Two types of drivers to choose from depending on your system configuration

Two types are available to choose from: a type with built-in positioning function and a pulse train input type to match the host system .

Positioning function built-in type

The information required for motor operation is set in the driver, reducing the burden on the host PLC. Settings are made using the data setter OPX-2A (sold separately), support software MEXE02, or RS-485 communication. For multiple axis control, the system configuration is simplified.

Type of driving

For the type with built-in positioning function, you set operation data such as operation speed and movement amount, and then select the operation data to operate. There are 4 operation types.

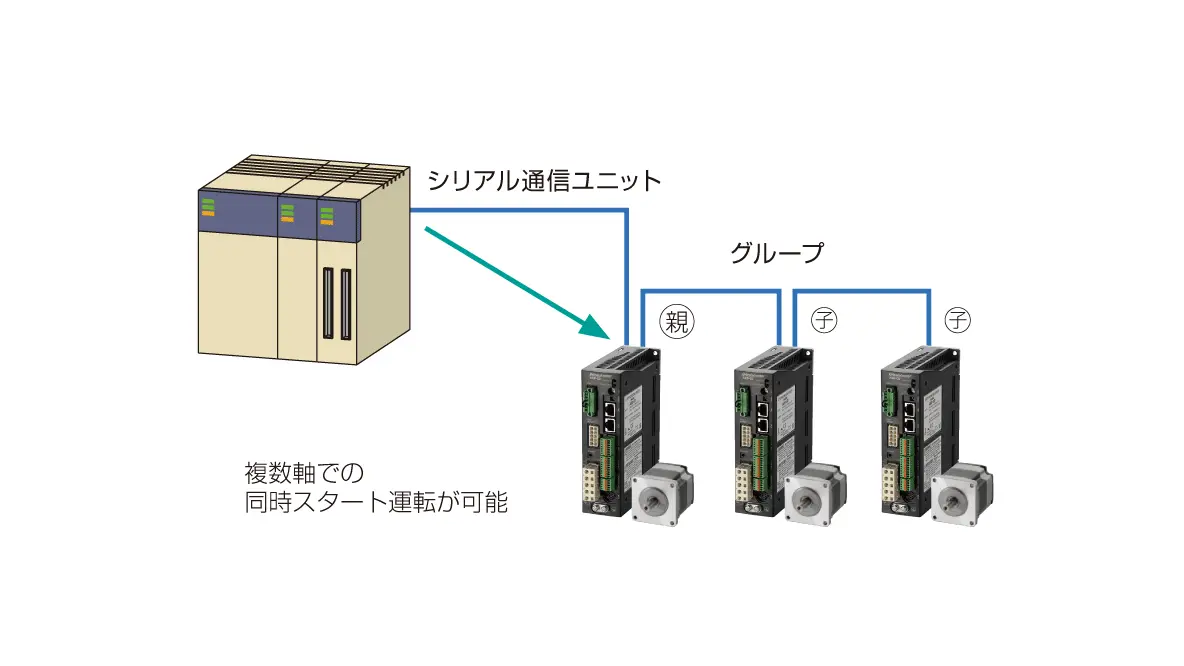

Group sending function

This function starts multiple axes simultaneously via Modbus (RTU) communication and FA network. Multiple drivers are grouped together, and when an operation command is sent to the parent unit of that group, all drivers in the same group as the parent unit will operate simultaneously. In the case of Modbus (RTU) communication, it also supports simultaneous movement amount/speed changes and monitoring.

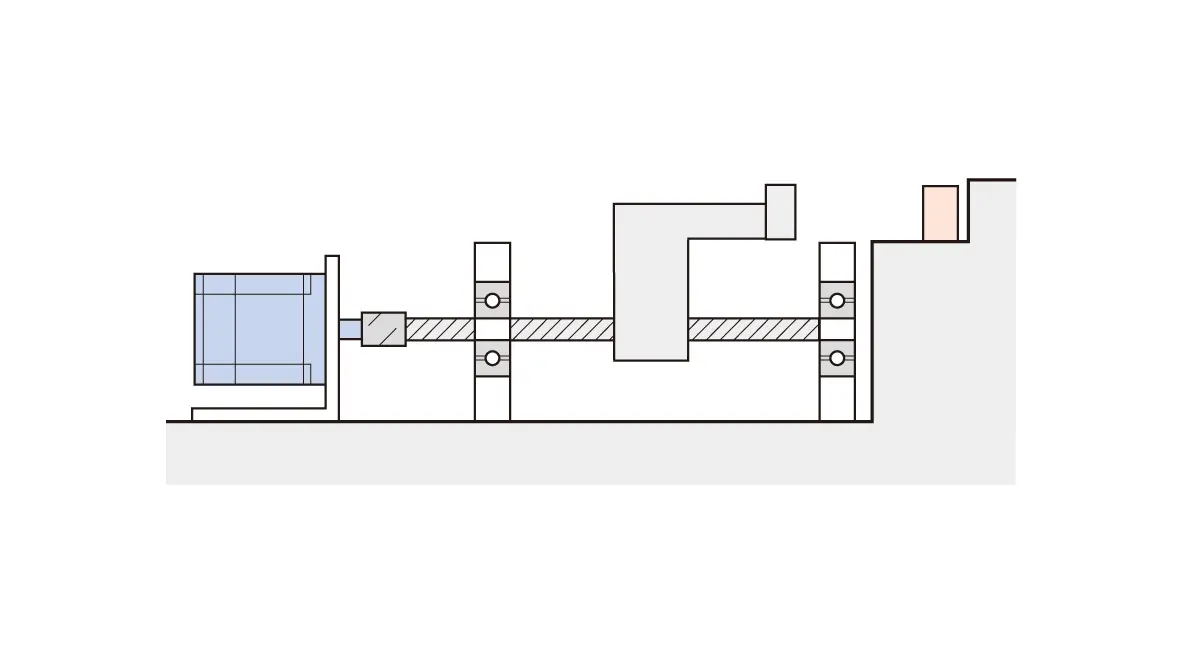

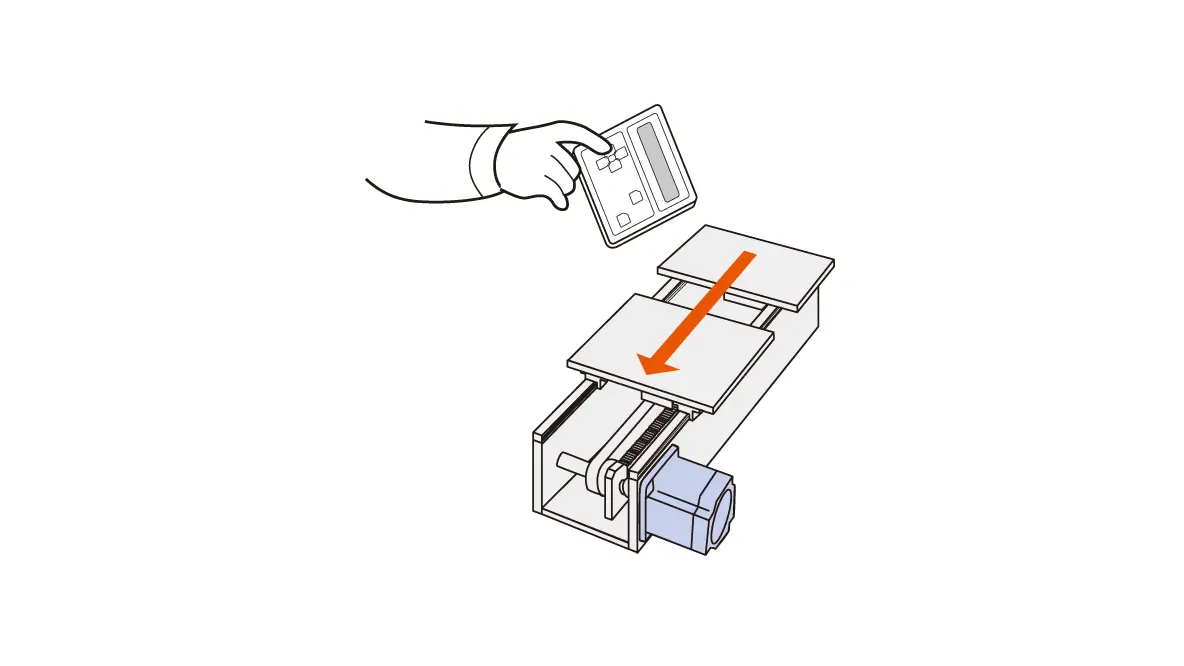

Teaching function

Teaching function

Teaching can be performed using the data setter OPX-2A (sold separately) or the support software MEXE02. The table is moved to the desired position, and the position data at that time is stored as positioning data.

System configuration by control type with built-in positioning function

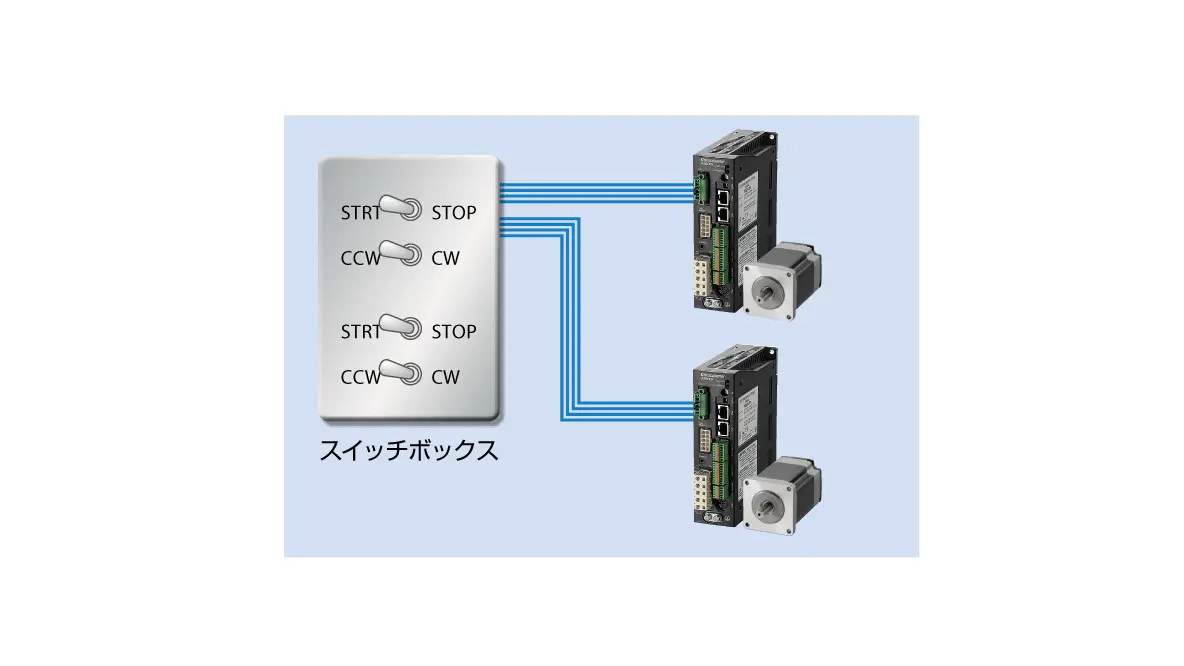

Switch box usage example – I/O controlLow-cost design

To set the operation data in the driver, simply connect it to a switch on hand to start and stop the motor. Easy control without using a PLC.

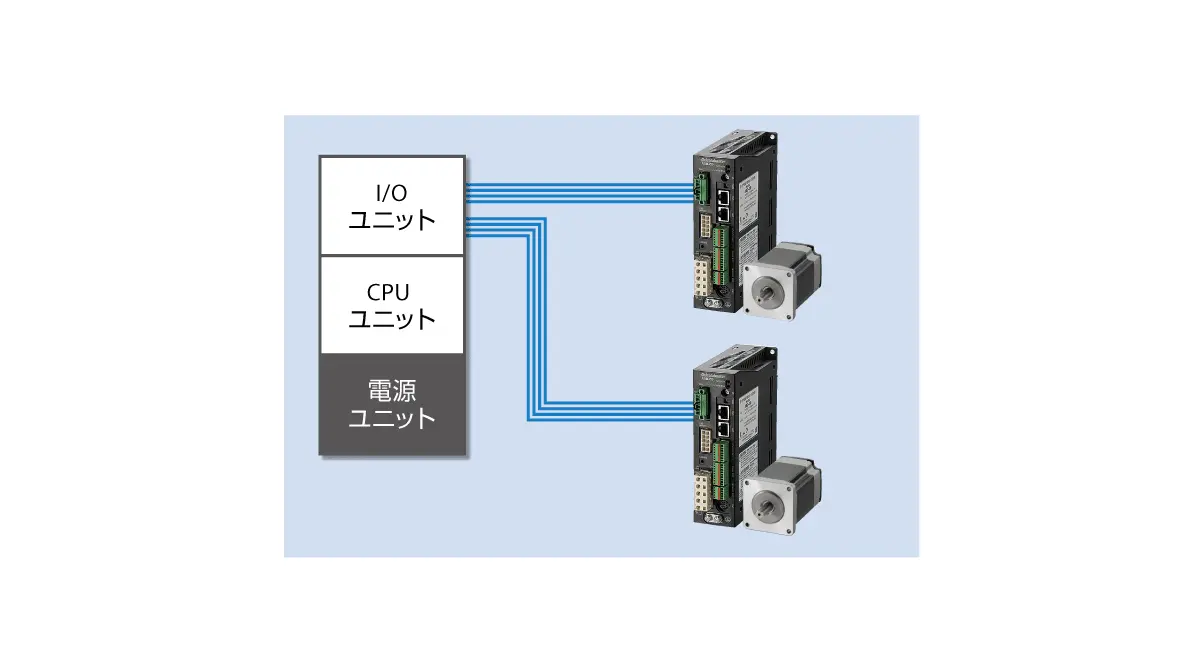

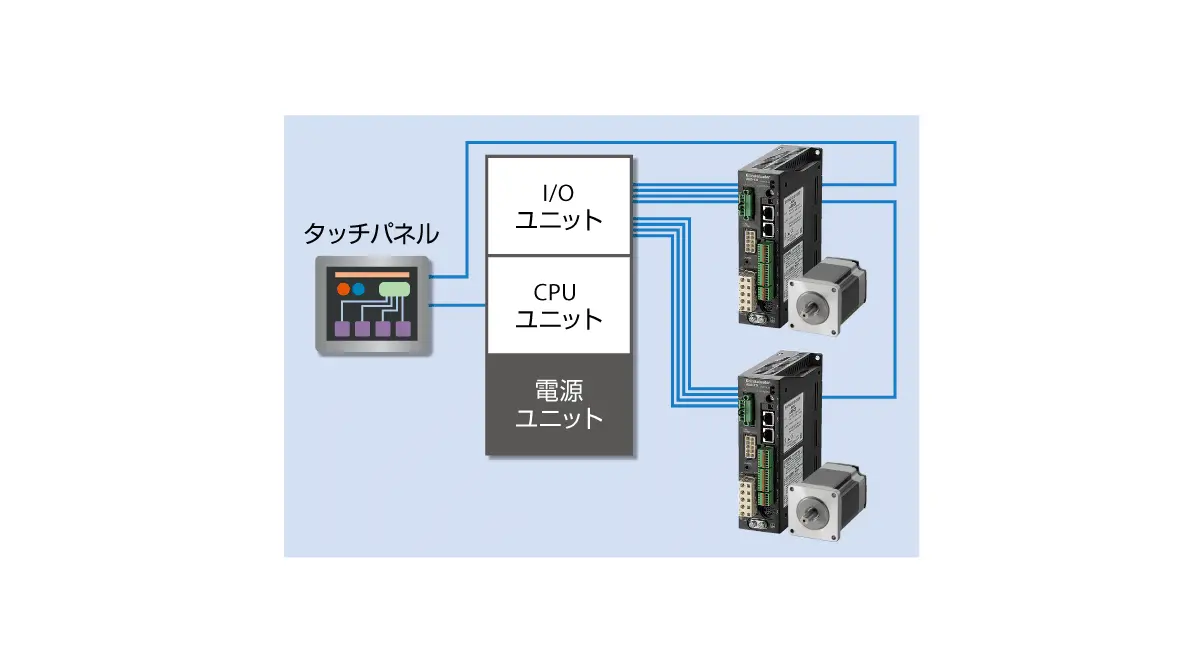

PLC Usage Example – I/O ControlLow-cost designSpace saving

When using a PLC, you can configure an operation system by directly connecting it to an I/O unit. Since a positioning unit is not required on the PLC side, this saves space and simplifies the system.

PLC/Touch Panel Usage Examples – I/O ControlSupports small lots of various products

Under normal circumstances, the motor is started and stopped by the I/O. Operation data settings can be changed, monitored, and alarms displayed on a touch panel that uses Modbus (RTU) communication. Even if there are many setups, they can be easily changed on the touch panel, reducing the burden of building a ladder.

Control via Modbus (RTU)/RS-485 communicationReduced wiringSerial unit compatibleComputer ControlSystem simplification

Operation data settings, parameter settings, and operation command inputs are performed via RS-485 communication. Up to 31 drivers can be connected to one serial communication unit, and multiple axes can be started simultaneously. It supports Modbus (RTU) and can be connected to touch panels, computers, etc.