Japan, Orientalmotor

Orientalmotor BLE2 Series Brushless Motors

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: BLE2 Series

Overview

The new motor structure is smaller than previous models and enables high power and high efficiency.

The driver equipped with the digital indication panel can easily set the speed.

Advantages of Brushless Motors

The brushless motor achieves high efficiency by employing permanent magnets in the rotor section.

The energy saving motors reduce power consumption and CO2 emissions.

Furthermore, the small size and light weight of the motor helps conserve resources and contributes to carbon neutrality initiatives.

Striving for User-Friendliness in Setting, Installation, and Wiring

Easy Setting With the Control Panel

The operation data and parameters can be set by using the operation keys or the setting dial while checking the digital indication.

The operation panel cannot be removed from the driver

Speed Setting Range

80~4000 r/min

(Varies with some gearheads)

Speed Regulation

±0.2 %

(at digital setting)

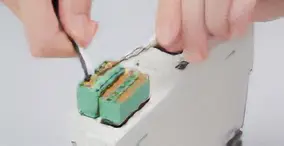

Quick and Reliable Wiring/Connecting

Quick and reliable wiring is possible thanks to the spring type connectors.

Effective Utilization of Installation Space

Multiple drivers can now be installed in contact with each other, making it possible to reduce the amount of installation space or increase the number of axes within the same equipment space.

Locking Lever Type Connector for Direct Connection

A locking lever type connector specifically designed for small motors allows direct connection between motor and driver.

Simple Connection

Cable connection is easy due to the locking lever that does not require screw fitting.

Installation Method

Insert the connector

Turn down the locking lever

Connection Completed

Direct Connection With Motors and Drivers*

Without an extension cable, a connection of up to 20 m is possible.

Flexible cables are also available

Use the flexible connection cable in applications where the cable is bent and flexed repeatedly.

Cable Outlet Direction Can be Selected

Supporting Customers With Enhanced Functions

The motors are equipped with 4 data setting methods and various functions that correspond with your purpose of use.

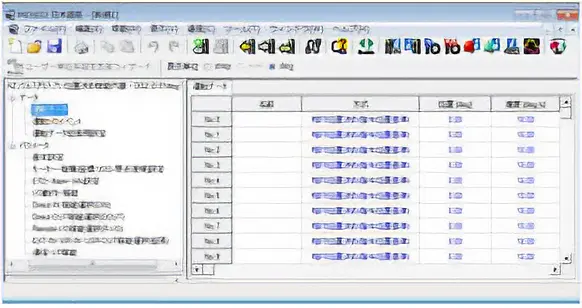

Using support software allows equipment start-up and operation status to be checked.

Operating Method

*When using the MEXE02 support software, the driver can be connected to the PC using a commercially available USB cable.

Setting Details

| Setting | Application and Purpose | Setting Value | Setting Method | |||

|---|---|---|---|---|---|---|

| Control Panel | External Speed Potentiometer PAVR2-20K | External DC Voltage | Support Software MEXE02 | |||

| Rotation Speed | Operation at the desired speed is available. | 80~4000 r/min | ● | ● | ● | ● |

| Torque Limiting | In addition to suppressing the max. output torque of a motor for safety purposes, the max. output torque can be limited according to the load. | 0~300 % | ● | ● | ● | ● |

| Acceleration/Deceleration Time | Acceleration time and deceleration time can be set to prevent excessive shock when starting and stopping. | 0.0~15.0 seconds | ● | - | - | ● |

| Multi-Speed Operation | Operation at 2 speeds or more is available. | Up to 16 speeds | ● | - | - | ● |

| Multi-Motor Control | Multiple motors can be operated at the same speed. | Less than 20 units (when a variable resistor is used) | - | ● | ● | - |

Main Functions of the Operation Panel and the MEXE02 Support Software

| Application and Purpose | Function | Description |

|---|---|---|

| Check the motor generated Torque | Load factor indication | Displays the load factor with the rated torque of the motor as 100 %. (Indication Range: 0~300 %) |

| Displays the conveyor transfer speed and the speed reduced by the gearhead | Gear ratio | When the gear ratio is set, the converted rotation speed can be displayed. |

| Operate the motor within the specified speed control range | Setting upper and lower rotation speed limits | Specify the upper and lower speed limit. |

| Changing the speed during motor operation | Speed teaching | Rotation speed in monitor mode during motor operation can be changed. |

| Simply hold the motor when stopped | Load holding function | Electrical holding torque can be generated when the motor is stopped. (Holding force up to 50 % of rated torque)

|

| Alleviate shock during starting and stopping | Impact softening filter | This function offers slow acceleration and stopping, so that the load being transported during starting and stopping does not move. |

| Check problem details | Alarm | This function enables you to identify and quickly respond to problems, including an overload, a disconnection or an operation error. |

| Use for operation verification and regular maintenance. | Information | Outputs before an alarm is generated.Inputting appropriate values for the parameters of each type of information will also help with equipment maintenance. |

| Protect specified data | Editing lock | Prohibit the editing/deletion of data and parameters with the driver’s control panel and local control operations. |

Useful Functions Utilizing Support Software MEXE02

By using the support software MEXE02, you can set and edit operation data and various parameters, as well as teach and monitor various conditions.

Comprehensive Support From Start-Up to Maintenance With a Variety of Functions

- Setting and Saving of Operation Data

- I/O Monitor

- Teaching, Remote Operation

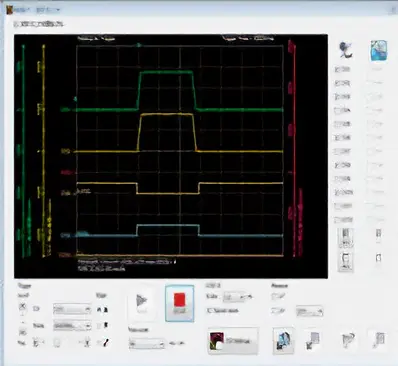

Waveform Monitor

Diagnostic and maintenance functions are available for trouble diagnosis and maintenance after operation is started.

- Alarm Monitor

- Status Monitor

- Information Monitor

IP67 Watertight, Dust-Resistant Motor That Can be Washed in Water

Excellent Protective Structure, Degree of Protection

Motor Structure

A sealing insert (O-ring) is used for the mating part to prevent water from entering the inside of the motor.

Connector Structure

The connector structure has a built-in gasket and O-ring for improved waterproofing.

It is IP67-compliant, including the connector part.

Improved Anti-Corrosion Properties

Special rust-resistant coating is applied, and stainless steel material is used for the output shaft and screws. The mounting surface is also painted to prevent rusting, even when assembled to stainless steel equipment.

Matches a Clean Environment

No cooling fan needed, because of the high efficiency motor. Therefore, there is no need to worry about generating dust from outside.

A Wide Variety of Gearheads to Choose From

In addition to the conventional parallel shaft gearhead GFV gearheads, a lineup of gearheads with features such as high gear ratio, high strength, and space saving is available. The permissible load and maximum permissible torque of the output shaft have been greatly increased.

Gearhead Types and Features

| Gearhead Type | Parallel Shaft Gearhead | Right-Angle Gearhead | Hollow Shaft Flat Gearhead | ||

|---|---|---|---|---|---|

| GFV Gearhead | JV Gearhead | JB Gearhead | JH Gearhead | FR Gearhead | |

| External View |  |  |  |  |  |

| Features |

|

|

|

|

|

| Output Power | 30 W, 60 W, 120 W 200 W, 300 W, 400 W | 200 W, 300 W, 400 W | 200 W, 300 W, 400 W | 60 W, 120 W, 200 W 300 W, 400 W | 30 W, 60 W, 120 W 200 W, 300 W, 400 W |

| Gear Ratio | 5~200 | 100~450 | 5~1200 | 5~200 | 5~200 |

| Rated Life | 10000 hours | 5000 hours | 5000 hours | 5000 hours | 10000 hours |

| Permissible Radial Load* | 1400 N | 3123 N | 3672 N | 2405 N | 2040 N |

| Permissible Axial Load* | 400 N | 480 N | 577 N | 550 N | 800 N |

| Permissible Torque* | 70 N·m | 198 N·m | 518 N·m | 82.8 N·m | 54 N·m |

*This value is for output power of 200 W, 3000 r/min, and the maximum gear ratio.

Related Products

-

Eagle Clamp VAFS Type Clamp for Horizontal Steel Plate

-

SAKUSAKU SG-43M-D Carbide Rotary Burr Three Pointed End Shape

-

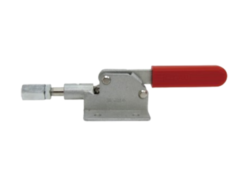

Kakuta No.51BXS-2S Straight Line Clamp

-

Kunimoto 0672001 KS Separator-Rebar Joint

-

Kanetec RMA-1545U Tilt Type Powerful Permanent Magnetic Chuck

-

NAGANO KEIKI CL14 Differential Pressure Switch