Japan, Orientalmotor

Orientalmotor BMU Series Brushless Motors

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: BMU Series

Rotate and Push. Easy Speed Control.

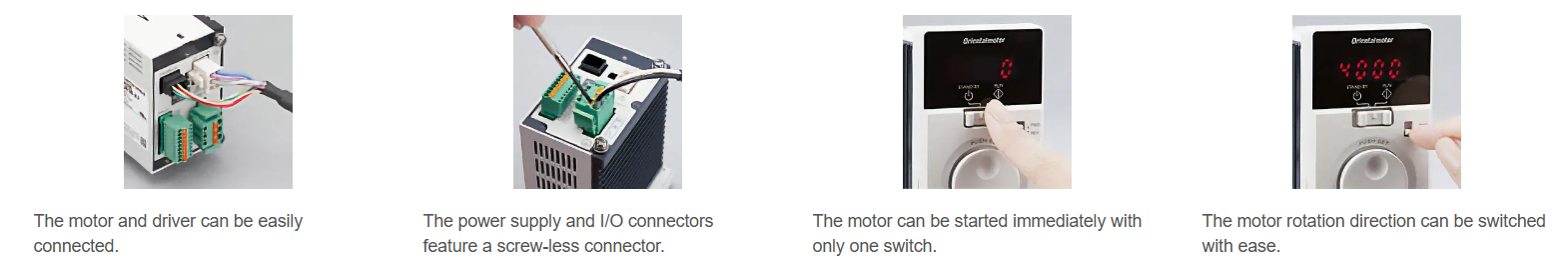

Simple Wiring. Immediate Start.

Maximum Rotation Speed 4000 r/min, Speed Ratio 1:50 (2.5 times higher than conventional products)

The BMU Series has a maximum speed of 4000 r/min. A speed ratio of 1:50 (80~4000 r/min) is achieved. Speed regulation has also been greatly improved from ±0.5 % to ±0.2 % of conventional products.

Advantages of Brushless Motors

The brushless motor achieves high efficiency by employing permanent magnets in the rotor section.

The energy saving motors reduce power consumption and CO2 emissions.

Furthermore, the small size and light weight of the motor helps conserve resources and contributes to carbon neutrality initiatives.

Full Functionality

Speed Display

Displays the motor rotation speed in increments of 1 r/min. Calculate the conveyor gear ratio and set the “Gear Ratio” parameter to display the conveyor transfer speed in m/s.

Load Factor Display

With the rated torque of the motor at 100 %, the load factor can be displayed as a percentage (40~200 %).

The load condition during start-up, as well as the load condition due to the aging deterioration of the equipment, can be confirmed.

Protective Function

Equipped with various protective functions, such as the overload protective function and the overvoltage protective function.

When any protective function is activated, the alarm code is shown on the display and the alarm signal is output.

4-Speed Operation

4-speed operation is possible by setting the data to operation data No. 0, No. 1, No. 2, or No. 3, and switching the input of the M0 and M1 terminals.

Note

When operating in 4-speed settings, the rotation direction of the motor cannot be changed by external input signals.

(30, 60, 120 W)

Setting the Acceleration/Deceleration Time

The setting for the acceleration time and deceleration time can be adjusted with the acceleration/deceleration time potentiometer, or can be done via the digital setting.

Setting Range: 0.0~15.0 sec (Initial value: 0.5 sec)

Fine adjustment of the shock mitigation is possible when starting and stopping the load, and the time can be freely set to match the takt time.

Output Shaft Holding When Stopped

The load can be electrically held when the motor is at standstill. (Holding force of approximately 50 % of the rated torque)

Note

If the power supply to the driver is turned OFF, the holding force dissipates. This cannot be used to prevent a fall during a power outage.

Other Functions

Setting Dial Operations Lock

When operating by an external signal, operation of the switch on the front panel can be set to “Invalid”.

Connector Type Direct Connection

Locking Lever Type Connector for Direct Connection (Connector type)

A locking lever type connector specifically designed for small motors allows direct connection between motor and driver.

Simple Connection

Cable connection is easy due to the locking lever that does not require screw fitting.

Installation Method

- Insert the connector

- Turn down the locking lever

- Connection Completed

Direct Connection With Motors and Drivers*

Without an extension cable, a connection of up to 10 m is possible.

Cable Outlet Direction Can be Selected

IP67 Watertight, Dust-Resistant Motor That Can be Washed in Water

Excellent Protective Structure, Degree of Protection

Motor Structure

A sealing insert (O-ring) is used for the mating part to prevent water from entering the inside of the motor.

Connector Structure

The connector structure has a built-in gasket and O-ring for improved waterproofing.

It is IP67-compliant, including the connector part.

Improved Anti-Corrosion Properties

Special rust-resistant coating is applied, and stainless steel material is used for the output shaft and screws. The mounting surface is also painted to prevent rusting, even when assembled to stainless steel equipment.

Matches a Clean Environment

No cooling fan needed, because of the high efficiency motor. Therefore, there is no need to worry about generating dust from outside.

New Connection Cable With IP66/IP67 Rating (For connector type)

Watertight, dust-resistant connection cable for relay connection of motors and drivers are now available.

The connector of the relay section is IP66/IP67-compliant

A Wide Variety of Gearheads to Choose From

In addition to the conventional parallel shaft gearhead GFV gearheads, a lineup of gearheads with features such as high gear ratio, high strength, and space saving is available.

The permissible load and maximum permissible torque of the output shaft have been greatly increased.

Gearhead Types and Features

| Gearhead Type | Parallel Shaft Gearhead | Right-Angle Gearhead | Hollow Shaft Flat Gearhead | ||

|---|---|---|---|---|---|

| GFV Gearhead | JV Gearhead | JB Gearhead | JH Gearhead | FR Gearhead | |

| External View |  |  |  |  |  |

| Features |

|

|

|

|

|

| Output Power | 30 W, 60 W, 120 W 200 W, 300 W, 400 W | 200 W, 300 W, 400 W | 200 W, 300 W, 400 W | 60 W, 120 W, 200 W 300 W, 400 W | 30 W, 60 W, 120 W 200 W, 300 W, 400 W |

| Gear Ratio | 5~200 | 100~450 | 5~1200 | 5~200 | 5~200 |

| Rated Life | 10000 hours | 5000 hours | 5000 hours | 5000 hours | 10000 hours |

| Permissible Radial Load* | 1400 N | 3123 N | 3672 N | 2405 N | 2040 N |

| Permissible Axial Load* | 400 N | 480 N | 577 N | 550 N | 800 N |

| Permissible Torque* | 70 N·m | 198 N·m | 518 N·m | 82.8 N·m | 54 N·m |

- *This value is for output power of 200 W, 3000 r/min, and the maximum gear ratio.

Related Products

-

BIX BX/BP Extension Type MG/Slide Magnet Type Impact Sockets With Magnet 「3/8”・1/2”」

-

Mirai Kogyo STEW-A3ОК, STEW-PBK Viewing Post (Lightweight Type)

-

Watanabe A5000 Series A5□□□-03 Digital Panel Meter for DC current

-

SAKUSAKU 16IR 14W Outer Thread Cutting Insert Whitworth 55°

-

SAKUSAKU GYG72060 Square End Mill 2-Flute

-

Eagle Jack (Konno Corporation) JUB 80 Steel Type Holding Block