Japan, Orientalmotor

Orientalmotor DH Series Hollow Rotary Actuator

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: DH Serie

Features

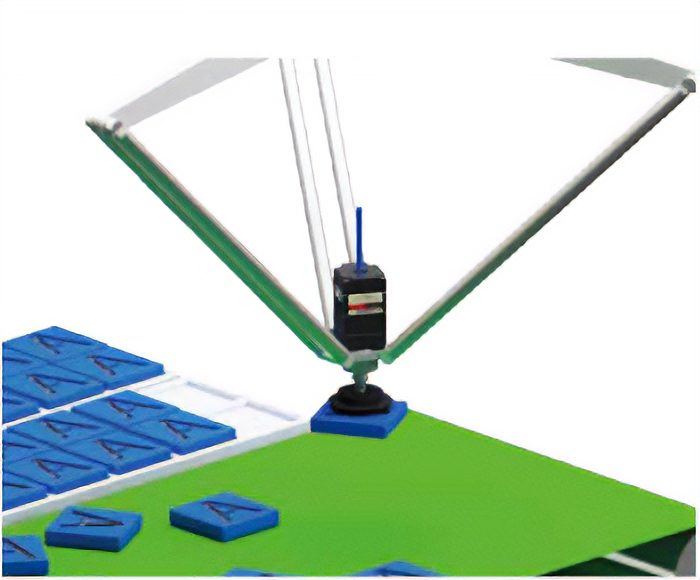

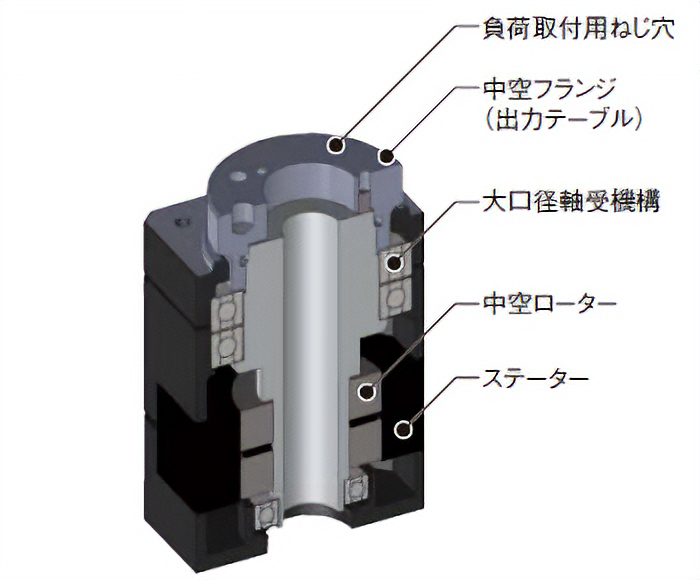

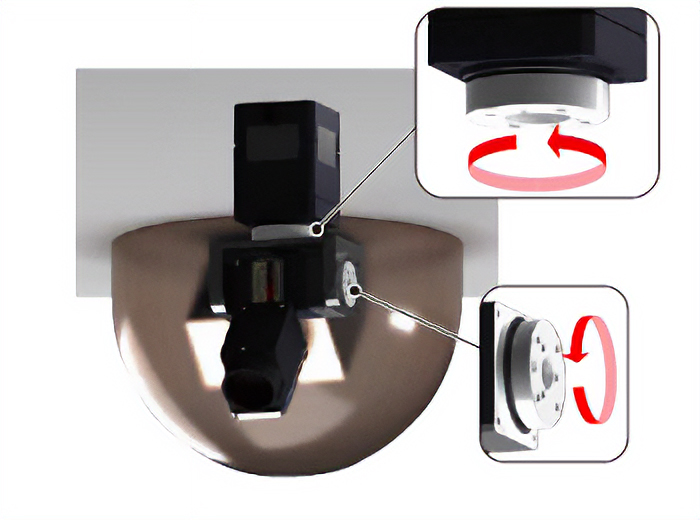

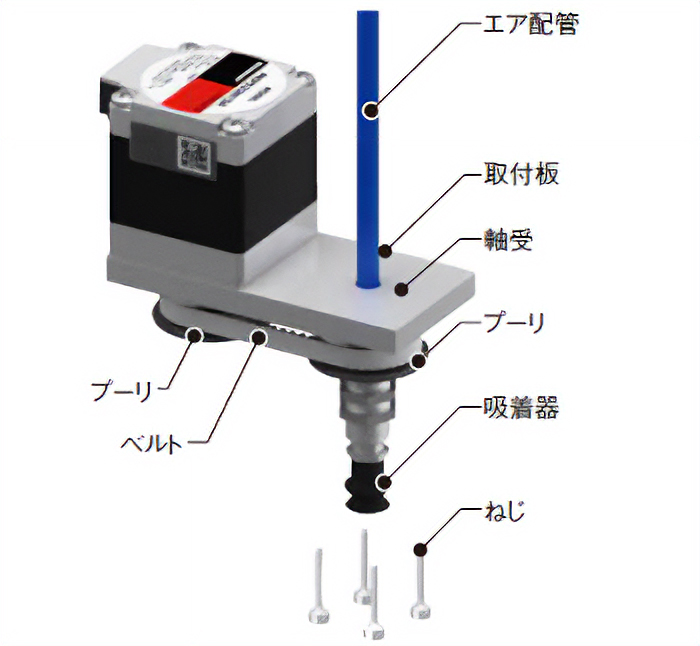

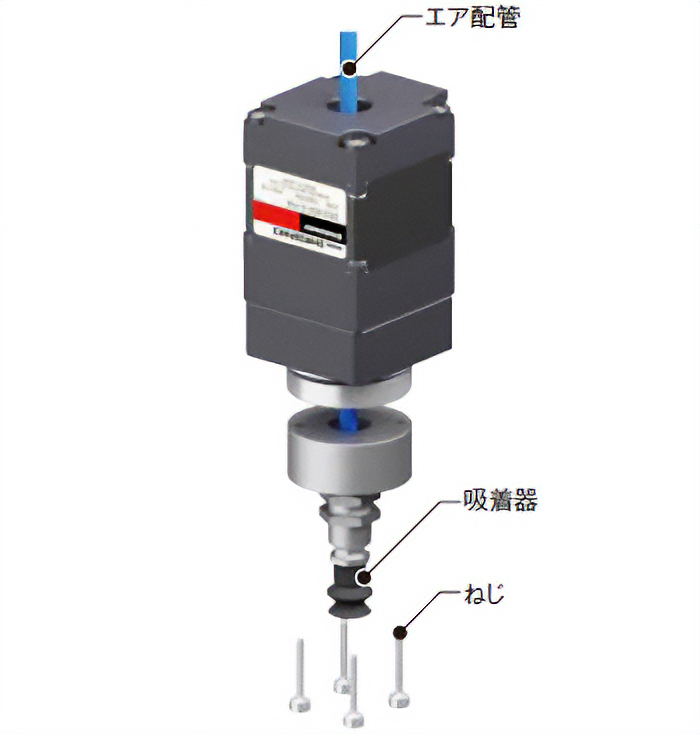

The hollow structure simplifies piping and wiring at the tip of the device.

This actuator uses a hollow flange for a 5-phase stepping motor. By passing air piping, wiring, and light through the hollow section, it contributes to simplifying the design of the device tip and making it smaller and lighter.

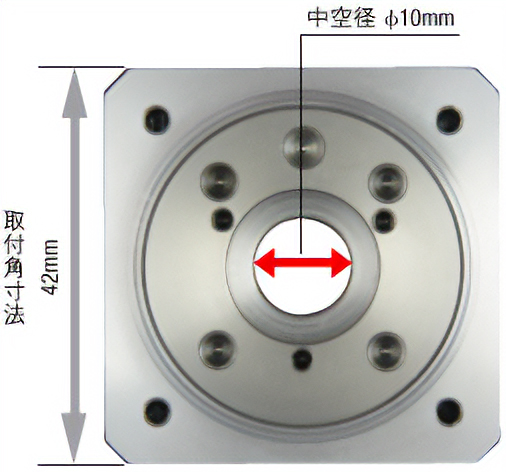

| Product name | Mounting angle dimensions | Hollow Diameter | mass |

|---|---|---|---|

| DHM28PAK2 | 28mm | φ5.2mm | 0.17kg |

| DHM42PAK | 42mm | φ10mm | 0.47kg |

Flange mounting helps reduce the number of parts around the moving part

A load can be attached directly to the hollow flange, helping to reduce the number of parts around the moving part.

Since parts that were previously prepared by customers themselves are no longer necessary, the time required for device design and part selection is reduced.

Furthermore, the time required for assembly and adjustment of installation accuracy is reduced, contributing to improved production efficiency for customers.

Benefits of adopting this device

- Reduce design time

- Parts cost reduction

- Reduce assembly man-hours

- Reduced time for precision adjustment

- Reduce maintenance time

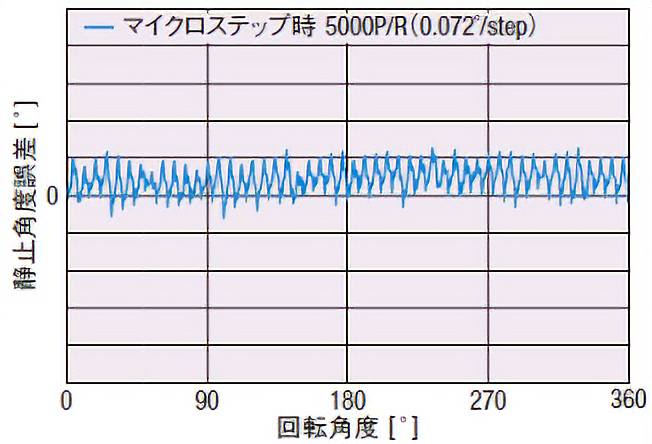

Achieves highly accurate positioning

Equipped with a 5-phase stepping motor, it can perform highly accurate positioning and repeat fine movements stably. When combined with a CVD driver, it can perform micro-step drive, and the smooth drive function suppresses vibrations at low speeds for smooth operation. In addition, since the hollow flange does not use a transmission mechanism such as a coupling or belt, there is no effect on accuracy due to component rigidity or combination errors.

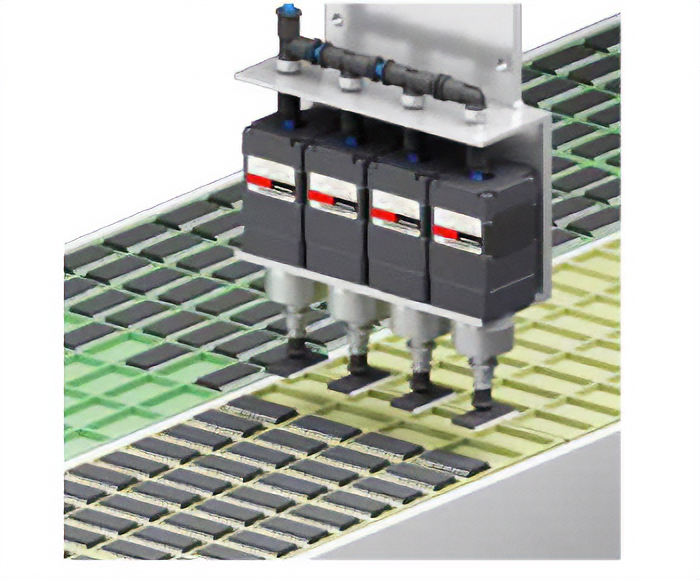

Benefits of adopting this device

- High precision part alignment

- Weight reduction of the adsorber unit

- Parallel arrangement reduces the size of the suction unit

Product name Static Angle Error Repeated positioning accuracy DHM28PAK2 ±0.33° ±0.15° DHM42PAK ±0.11° ±0.05°

Line up

Actuator

| Product name | Mounting angle dimensions | Hollow Diameter | Static Angle Error | Repeated positioning accuracy | Maximum static torque |

|---|---|---|---|---|---|

| DHM28PAK2 | 28mm | φ5.2mm | ±0.33° | ±0.15° | 0.029N・m |

| DHM42PAK | 42mm | φ10mm | ±0.11° | ±0.05° | 0.175N・m |

Driver

| Driver Type | Input Power | |

|---|---|---|

| Pulse train input | DC24V | |

| RS-485 communication |

Connection cable/Flexible connection cable

Mounting angle: 28mm

- If the cable is to be bent, use a flexible connection cable.

- We also offer a “relay cable driver side” that can be added to the connection cable.

| Length [m] | |

|---|---|

| 0.5–10 |

The driver has a connector.

- If the cable is to be bent, use a flexible connection cable.

- An “extension connection cable without terminal processing” between the motor and driver is also available.

| Length [m] | |

|---|---|

| 0.5–1 |

please note

The wiring distance between the motor and driver should be 10m or less.

Related Products

-

Super Tool SJC0.5S, SJC1S Screw Cam Clamp (J-Type, Twist Cam Type)

-

Toho Seisakusho VVC-2702AF Type Electric High-Speed Ball Valve

-

SHIGEMATSU DR28SL2W Dust Respirator

-

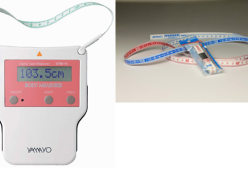

Yamayo DTM-15 Digital Body Measure & MM-15 Body Measure

-

SHIGEMATSU AP-07 Powered-Air Purifying Respirators

-

Howa MBN-350VCT1K Vertical Machining Center (Inline Type/MBN-Series)