Japan, Orientalmotor

Orientalmotor DRS2 Series Compact Electric Cylinder

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: DRS2 Series

Major features

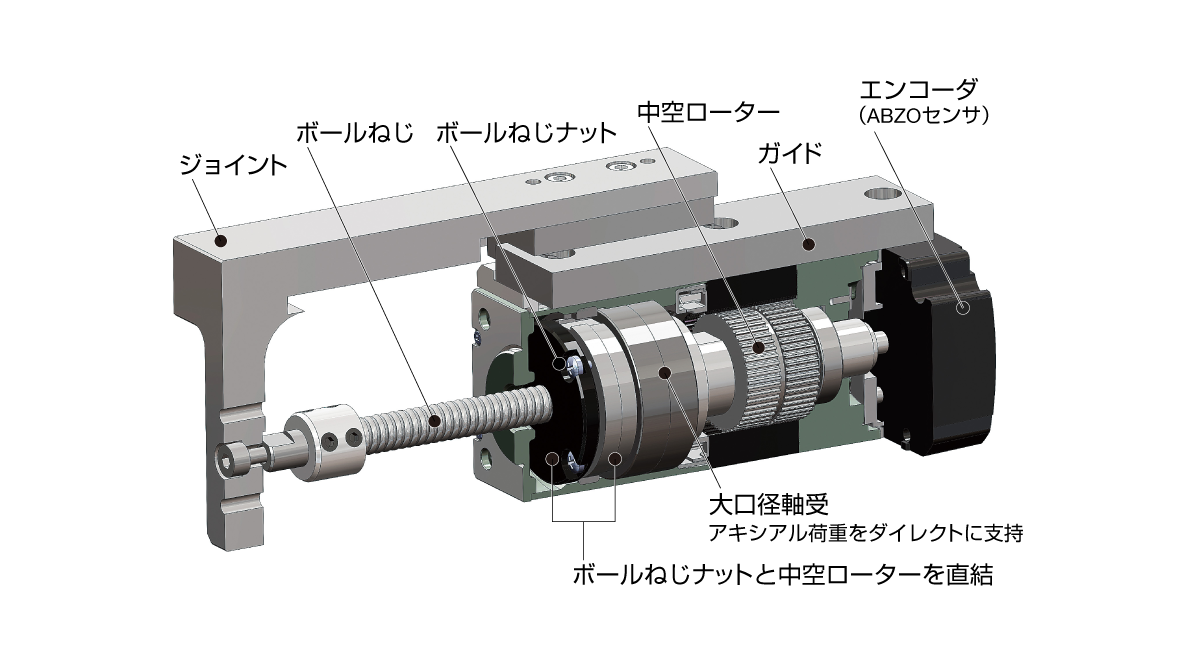

αSTEP and ball screw integrated structure

High-precision positioning is achieved by combining the high-precision αSTEP with a ball screw.

By integrating the hollow rotor and ball screw nut without using connecting parts such as couplings, the effects of backlash caused by component rigidity and combination are reduced.

Two types of drive ball screws

| Drive Ball Screw | precision | Rolling |

|---|---|---|

| Repeated positioning accuracy | ±0.003mm | ±0.01mm |

| Minimum Movement | 0.001mm | |

Achieves high payload and high speed operation *

| Lead | 2mm | 8mm |

|---|---|---|

| Payload capacity (horizontal and vertical) | 10kg | 5kg |

| maximum speed | 50mm/s | 200mm/s |

- *The specifications in the table are for a guided type with a mounting angle of 42 mm.

We have prepared a support tool that can calculate the approximate positioning time for applicable our electric actuator products according to the “model” and “operating conditions.”

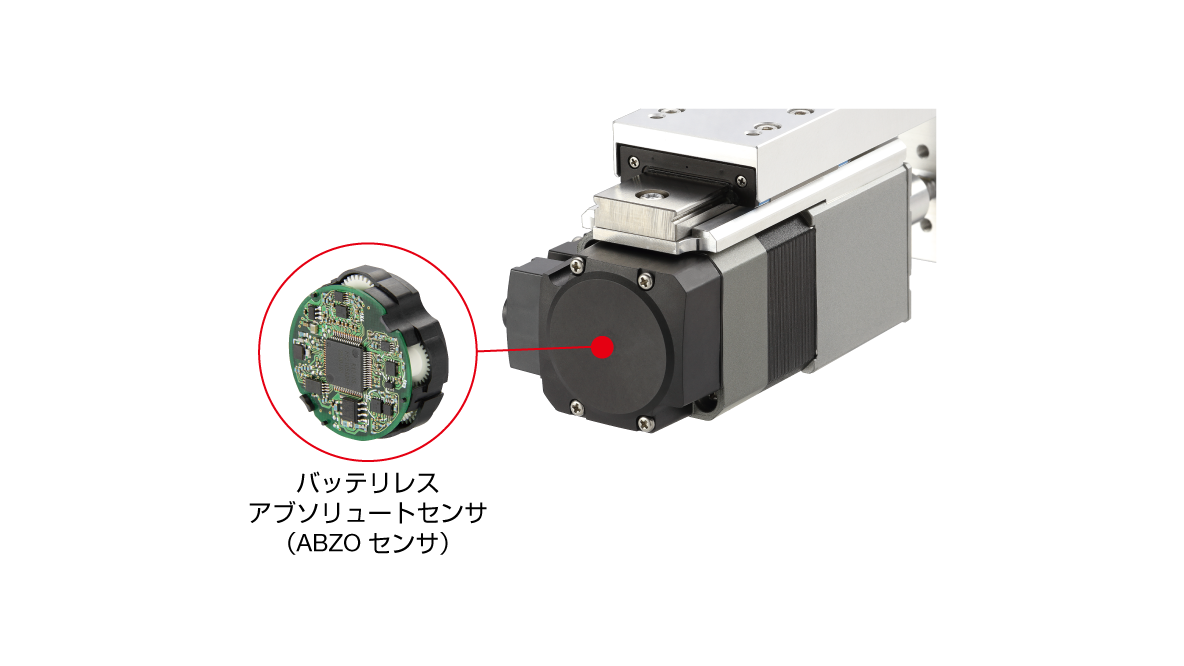

Equipped with αSTEP AZ series drive motor

- Built-in battery-less absolute sensor, constantly monitors motor position information without the need for an external sensor

- High reliability through closed loop control

- High efficiency reduces motor heat generation and saves energy

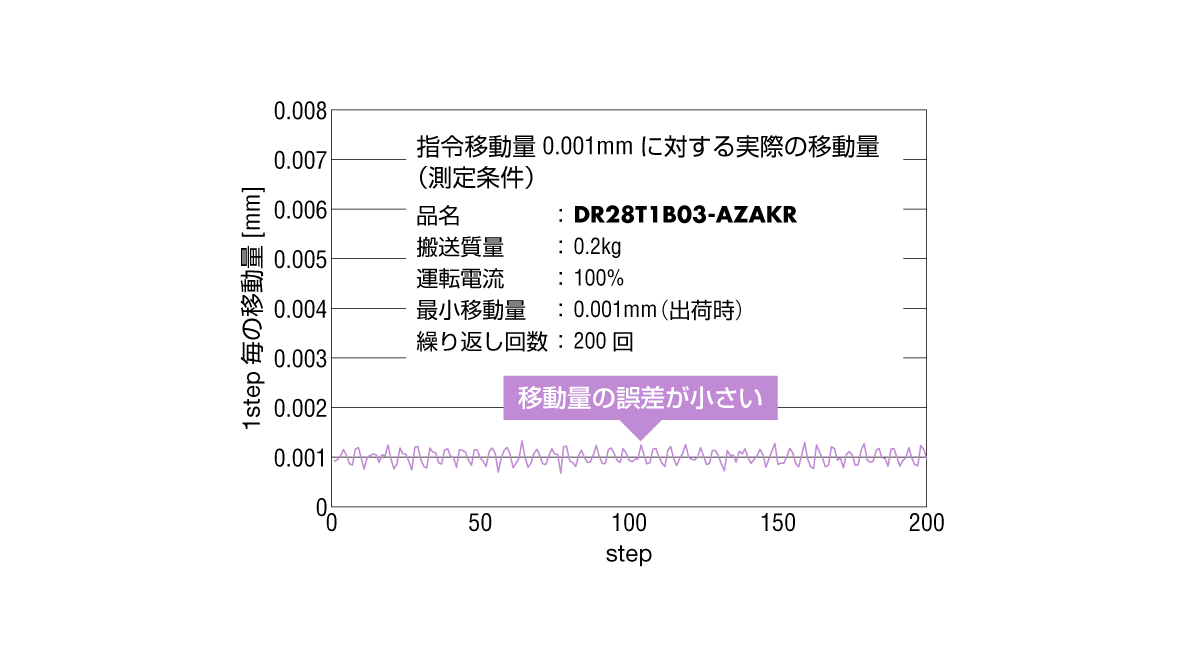

Stable fine feeding is possible

Equipped with αSTEP, it is possible to stably repeat minute movements one step at a time, making it ideal for fine adjustments to cameras and lenses.

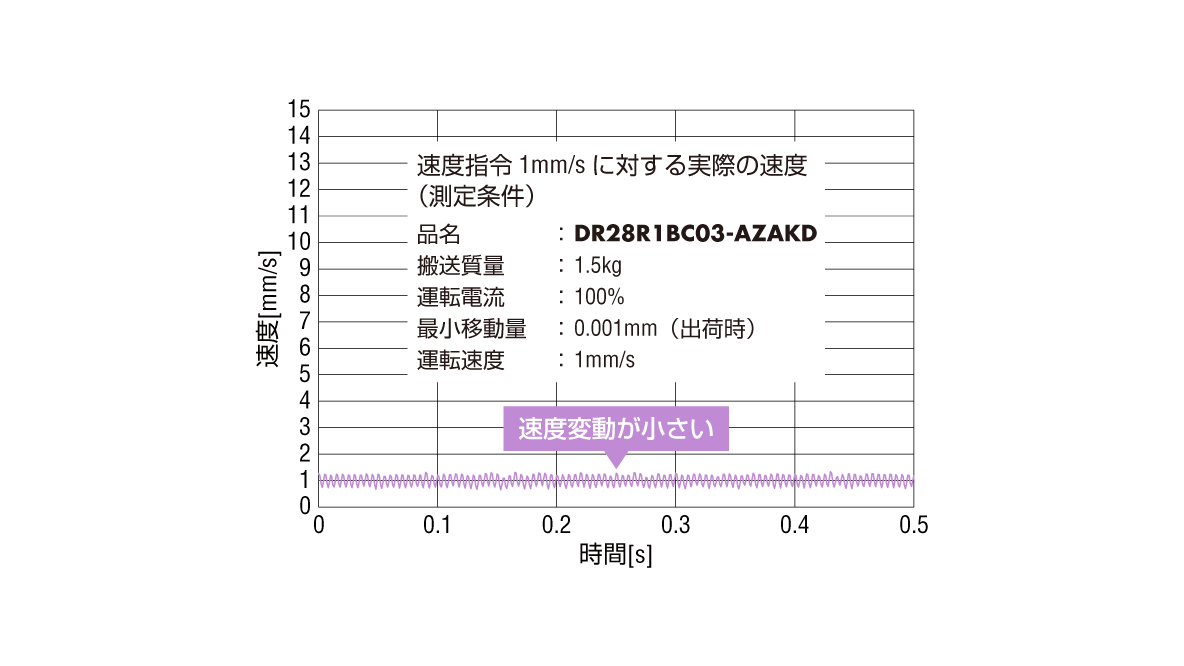

Slow and smooth movement

The micro-step drive and smooth drive functions * suppress vibrations at low speeds, allowing smooth movement. Ideal for the drive shaft that steadily supplies solution from a syringe.

- * This control automatically drives in microsteps at the same movement distance and speed as in full step without changing the pulse input settings.

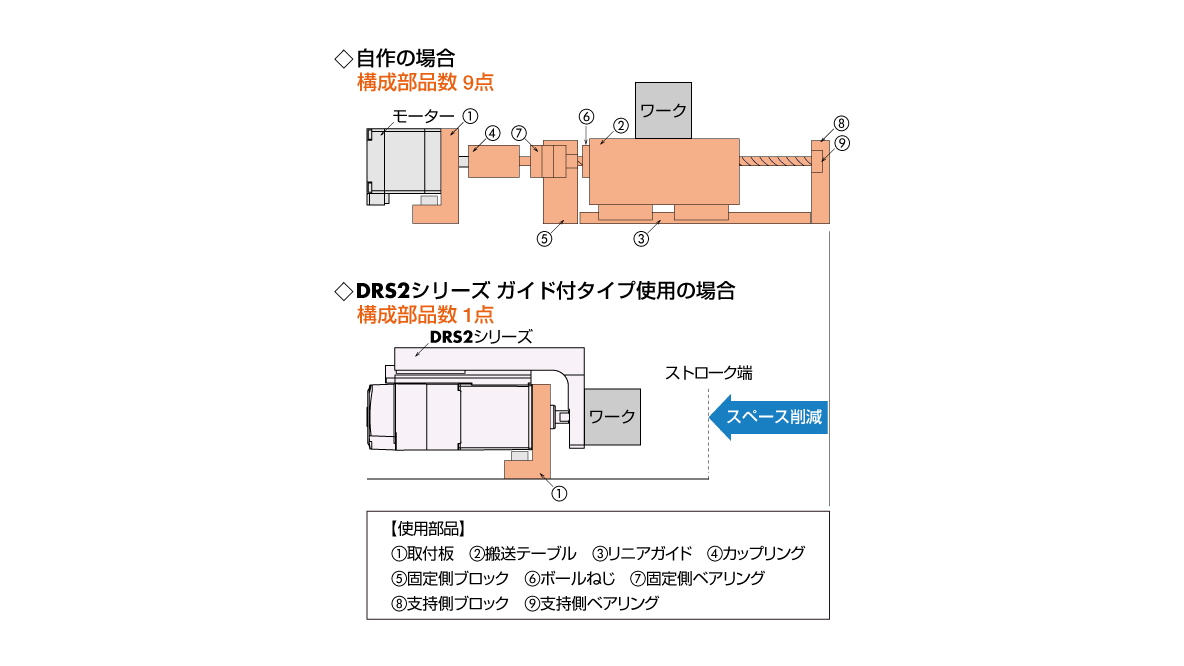

Contributes to smaller and lighter equipment

The compact body that integrates αSTEP and ball screws contributes to downsizing and space saving of equipment.

The weight reduction of the equipment tip is expected to improve design freedom.

Types and additional functions can be freely combined

Guide Type

This product is equipped with a highly rigid guide that can secure a load to the cylinder.

It is easy to directly attach a load.

No guide type

It can be directly built into equipment due to its compact shape without guides, etc.

It can also be used as a compact thrust shaft in the load transport guide of equipment.

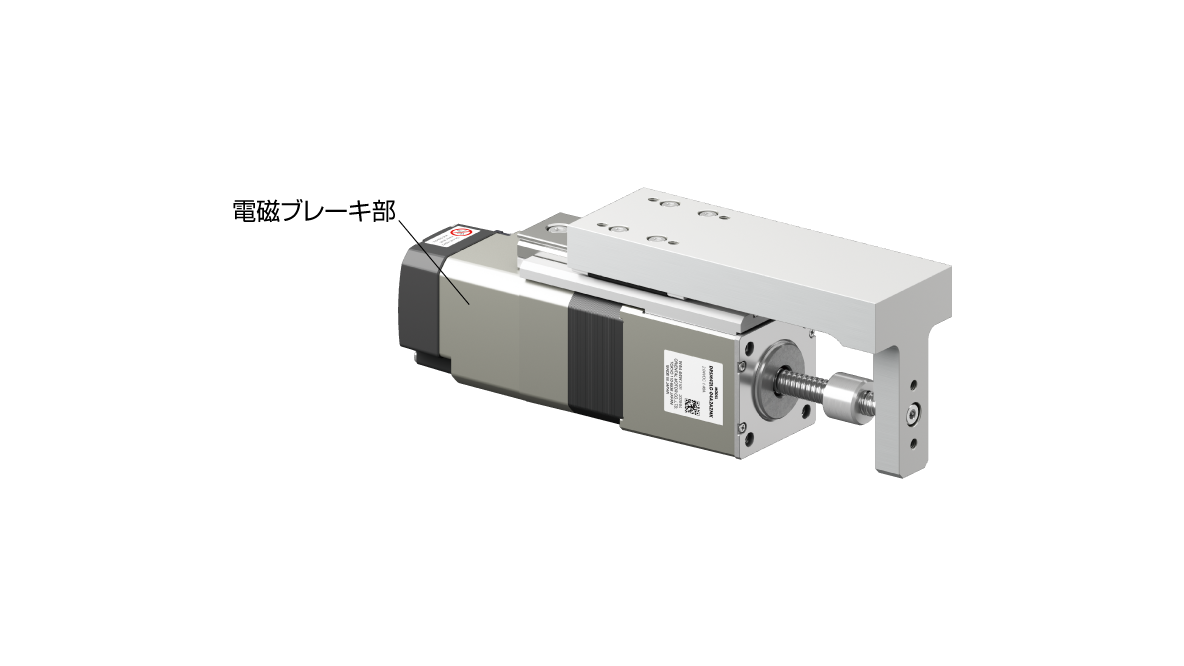

Lineup includes guided and non-guide types with electromagnetic brakes

We offer a lineup of models with electromagnetic brakes that operate without excitation. The stopped position can be maintained when the power is turned off. Even if installed vertically, there is no need to worry about the workpiece dropping during maintenance work.

Shorten the time it takes to start up equipment

Linear motion mechanism concentrated in a compact body

Since there is no need to manufacture parts yourself, you can reduce the time required for “designing equipment and selecting parts” and “adjusting assembly and installation precision,” which leads to more efficient equipment startup.

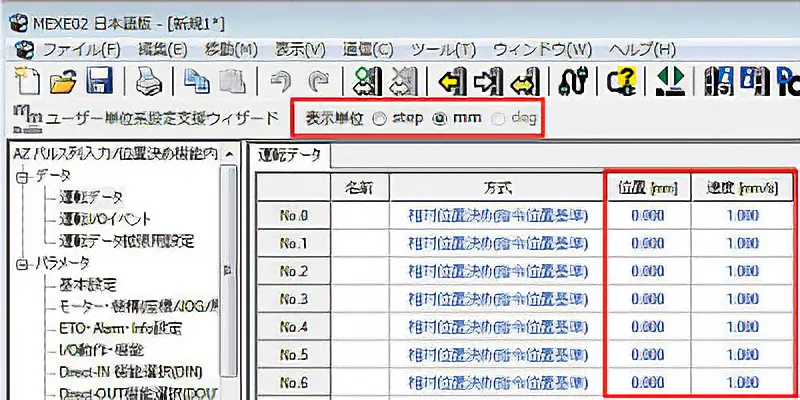

Parameters required for operation are already set

Mechanical parameters such as lead and stroke are set by the ABZO sensor at the time of shipment. After purchase, they can be set in units of mm, which contributes to shortening the start-up time of the equipment.

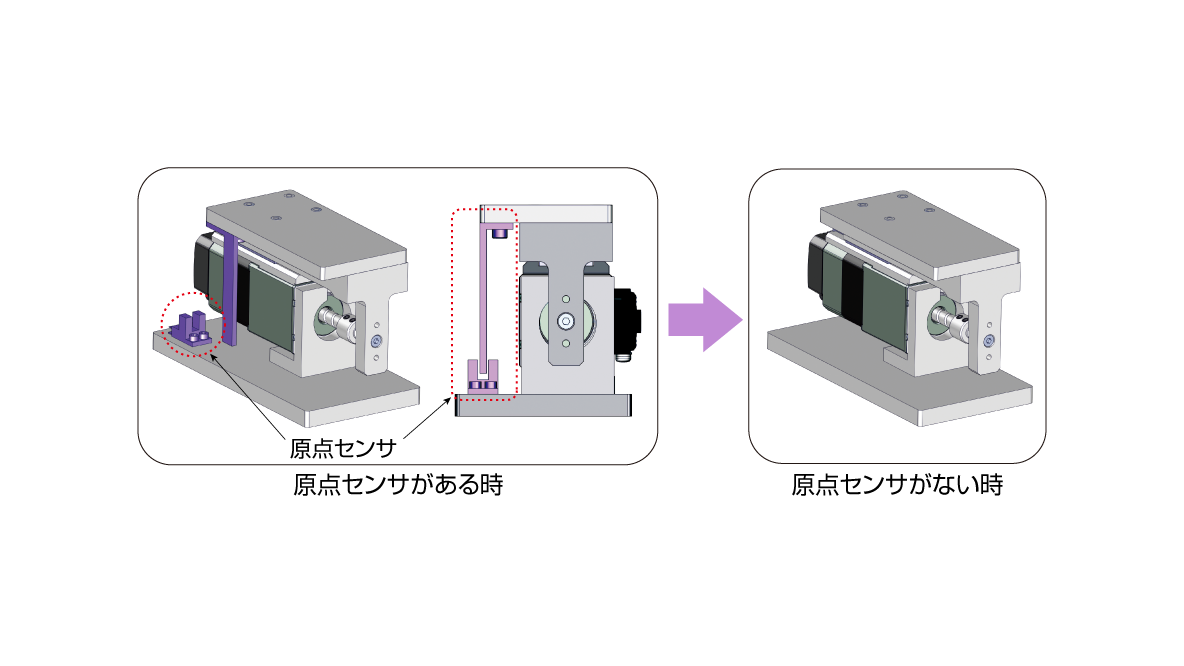

No origin sensor required

Position information is mechanically managed by the ABZO sensor, so there is no need for external sensors such as origin sensors or limit sensors. This also avoids the trouble of periodic maintenance that occurs when using external sensors.