Japan, Orientalmotor

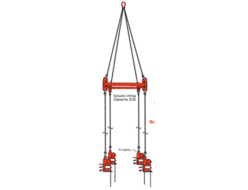

Orientalmotor LJ Linear Heads Combination with ASTEP AZ Series Rack-and-Pinion System

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: LJ Linear Heads

Compact Size and Maximum Transportable Mass of 200 kg

Maximum Transportable Mass 200 kg

Larger-diameter pinion with increased gear strength realizes a maximum transportable mass of 200 kg

Maximum Stroke 700 mm

Lineup of strokes from 100~700 mm

Comparison With Electric Linear Slide

A rack-and-pinion system can transport the transportable mass if it is mounted without consideration of the moment of inertia

Overview of Rack-and-Pinion System

The rack-and-pinion system can easily convert the rotation of the motor into linear motion.

Although the linear motion mechanism part is compact in design, it can transport a large load due to its high strength processing.

Contributing to Design Efficiency

Reduces Startup Time From Design

In comparison to building a rack-and-pinion mechanism yourself, the number of parts used and the man-hours required for design and assembly can be reduced.

Space Saving

The motor can run by itself by fixing both ends of the rack. Effective for installation where motor space is difficult to secure.

Reduced Labor for Assembly and Maintenance

Can be Easily Combined With a Parallel Shaft Gearhead

Installation and maintenance of the motor can be easily performed.

The Rack Can be Mounted Both Horizontally and Vertically

The ability to freely choose the mounting direction adds to improved ease of design and cost reductions through the sharing of parts.

Applications

The rack-and-pinion system, which can be applied to a variety of applications, is a user-friendly product that can be selected as if it were a component.

Bucket Transfer Belt Conveyor

- ① Rack is fixed and motor section moves vertically

- ② Motor is fixed and rack moves horizontally

Machine Parts Cleaning Equipment

- ① Motor is fixed and rack moves vertically

- ② Rack is fixed and motor moves horizontally

Real examples from the Oriental Motor production facilities of load elevating and lowering equipment used to explain points for adoption of products.

Oriental Motor’s extensive product lineup and wide range of services contribute to overall reduced costs, by shortening startup times, and equipment design with specifications to meet your needs.

Labor-Saving Ideas

At Japan’s Manufacturing sites, labor shortages due to a decline in the working population associated with the decreasing birthrate and aging population is becoming an issue. Amidst this, there is an urgent need for labor-saving that reduces the burden of “heavy lifting work” and “repetitive work such as sorting.” Rack-and-pinion system that transports high loads contributing to labor-saving in manufacturing operations.

Loading and unloading of buckets, which places a burden on the body. Automatic lifting equipment using a rack-and-pinion system can reduce the burden on the operator.

Battery-Free Absolute Encoder Equipped

It is equipped with a small battery-free mechanical absolute encoder (ABZO sensor). This can help improve productivity and reduce costs.

- Mechanical-Type Sensor

Retains positioning information even when power is not supplied - Multi-Rotation Absolute Encoder

Absolute position detection is possible with ±900 (1,800) revolutions of the motor shaft from the home position

No External Sensors Required

As it is an absolute system, home sensors or limit sensors are not required.

Advantages

- Improved High-Speed Return-to-Home + Return-to-Home Accuracy

- Reduced Cost

- Simple Wiring

- Not Affected by External Sensor Malfunction

Battery-Free

Mechanical sensors do not require batteries.

Positioning information is managed mechanically by the ABZO Sensor.

Advantages

- No need to replace batteries

- Unlimited Driver Installation Possibilities

- Safe for Overseas Shipping

Simplifying the Main Program via Sequence Function

The AZ Series come equipped with a wide variety of sequence functions such as timer settings for linked operation and during operations, conditional branching, and loop operation. (excluding some models)

It can be set up using the support software MEXE02, which simplifies the sequence program of the host system.

- Positioning Operation Data Setting Value (max. 256)

- General-Purpose I/O Signal Counts (Input 10, Output 6)

- Communication I/O Signal Counts (Input 16, Output 16)

Return-to-Home Not Required (Built-in controller type)

Even if the power shuts down during a positioning operation, the position information is retained. With the built-in controller type, the positioning operation can be restarted without performing return-to-home, after an emergency stop on the production line or a blackout.

Data Collection of Motor Operation Status and Functions Useful for Preventive and Predictive Maintenance

This software is equipped with various monitoring functions for checking the operating status of the motor.

By using different types of equipment for different situations, it is possible to shorten the start-up and adjustment time of the equipment, as well as to utilize it for maintenance and servicing.

Information Functions Useful for Preventive and Predictive Maintenance

By setting arbitrary numerical values for the monitor items of each source of information, external signals can be output when the values are reached.

Importing this information into the host controller helps in early detection of problems and adjustment of product maintenance timing.

Examples of Information Functions

TRIP Information

You can set the number of rotations you want to output in advance, and output when that number is reached. (Motor operation will continue)

Temperature Information

You can set the desired output temperature in advance, and the driver will output when it reaches that temperature. (Motor operation will continue)

Standardized Wiring, Control, and Maintenance Parts

Various actuator products equipped with the αSTEP AZ Series are available.

Each of them has the same motor and driver, for standardized wiring, control, and maintenance parts.

Wiring Standardization

The wiring for motor cables, input/output signals, and the power supply is the same.

Control Standardization

These products can be operated via the same method, since the control method is the same. For the network control, the remote I/O and the command code are also the same. It saves you the trouble of creating a program.

Unification of Maintenance Parts

Maintenance parts can be minimized, since the motor, driver, and cable are common to all. Management costs (parts cost, management space) can be reduced.

Products Equipped With the AZ Series

Electric Actuators (AZ Series equipped)

| Electric Linear Slides | Electric Cylinders | Compact Electric Cylinders | Rack-and-Pinion System | Electric Grippers | Hollow Rotary Actuators |

|---|---|---|---|---|---|

| EAS Series EZS Series EZSH Series | EAC Series | DR Series DRS2 Series | L Series LJ Linear Heads | EH Series | DGII Series |

- The power supply input of the installed motor differs between Series. Please refer to each series page for the detailed product line.

Driver Features and Product Line

Drivers That Can be Selected to Match the Host Controller

| Driver Type | Compatible Interfaces | Single Axis Driver | |

|---|---|---|---|

| AC Input | |||

| |||

| Network Compatible | Drivers are controlled directly from a host control device through industrial network | EtherCAT | ○ |

| EtherNet/IP™ | ○ | ||

| PROFINET | ○ | ||

| MECHATROLINK-Ⅲ | ○ | ||

| SSCNETⅢ/H | ○ | ||

| Built-in Controller | Operation data is built into the driver.Controllable via Modbus (RTU) and I/O. Can be controlled via CC-Link by using a network converter. | Modbus (RTU) I/O CC-Link* | ○ |

| Pulse Input with RS-485 Communication | Controlled by pulse signal. Motor status information can be monitored via Modbus (RTU). | Pulse input Modbus (RTU) | ○ |

| Pulse Input | Controlled by pulse signal | Pulse input | ○ |

- *EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

- *EtherNet/IP™ is a trademark of ODVA.

- *PROFINET is a trademark or registered trademark of PROFIBUS Nutzerorganisation e.V. (PNO).

- *MECHATROLINK is a registered trademark of the MECHATROLINK Members Association.

- *SSCNETⅢ/H is a registered trademark of Mitsubishi Electric Corporation.

- *CC-Link is a registered trademark of the CC-Link Partner Association.

Product Line

Please purchase the linear head, geared motor, driver, and connection cable separately.

LJ Linear Heads Combination With AZ Series

| Rack Moving Direction | Frame Size [mm] | Type | Power Supply Input | Transportable Mass [kg] | Operating Speed Range [mm/s] | Stroke [mm] | Motor | Electromagnetic Brake |

|---|---|---|---|---|---|---|---|---|

| 90 | - | AC | 25 | 0~500 | 100~700 | AZM98-TS10 | Equipped/Not equipped |

| 65 | 0~200 | |||||||

| 35 | 0~282 | AZM98-TS20 | ||||||

| 130 | 0~50 | |||||||

| 55 | 0~188 | AZM98-TS30 | ||||||

| 200 | 0~40 |

Drivers

| Driver Type | Power Supply Input [V] | |

|---|---|---|

| Built-In Controller | Single-Phase 100-120 Single-Phase/Three-Phase 200-240 | |

| Pulse Input With RS-485 Communication | ||

| Pulse Input | ||

| EtherCAT Compatible | ||

| EtherNet/IP Compatible | ||

| PROFINET Compatible | ||

| MECHATROLINK-III Compatible | Single-Phase 100-120 Single-Phase/Three-Phase 200-240 | |

| SSCNET III/H Compatible |

Connection Cable Sets/Flexible Connection Cable Sets

- Motor cable from motor cannot be connected directly to driver. Find the right connection cable.

- Use flexible connection cables in applications where the cable is bent.

| Length [m] | |

|---|---|

| 0.5~20 |

|