Japan, Orientalmotor

Orientalmotor NX Series Servomotor

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: NX Series

Features

Easy operation

Unlike stepping motors, it can stably drive large inertia and belt mechanisms without gain adjustment. Also, by manually adjusting the gain, it can be operated under more severe load conditions.

Achieves high inertia drive

Auto-tuning allows operation up to 50 times the rotor inertia, while manual tuning allows operation up to 100 times the rotor inertia.

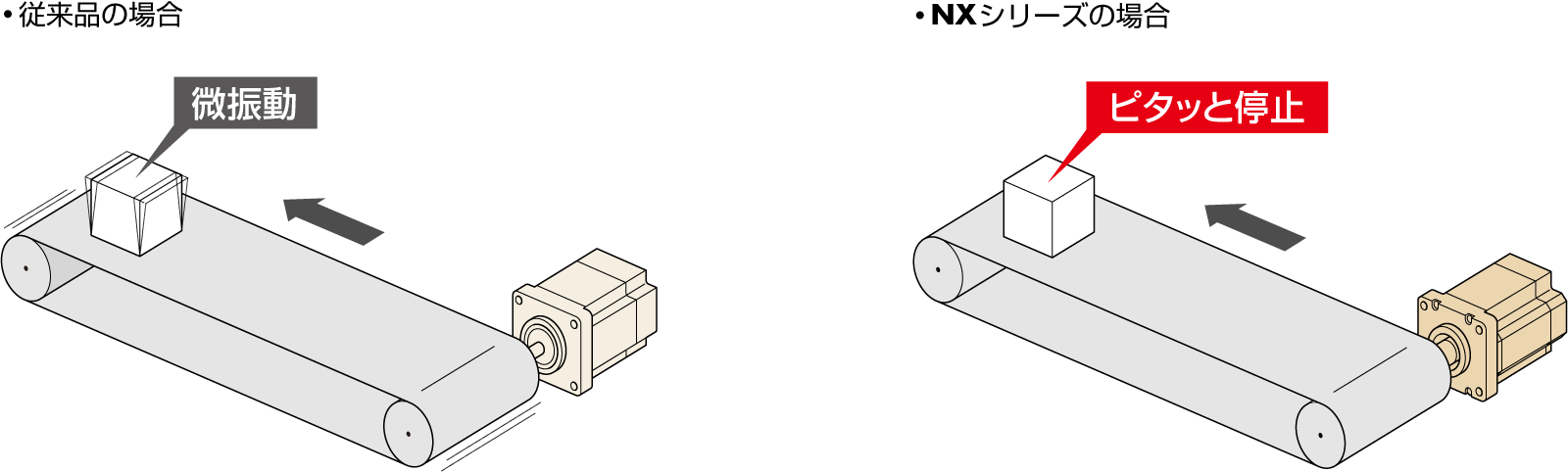

Belt mechanism ensures smooth operation

The belt mechanism operates similarly to a stepping motor and avoids any vibrations that occur before stopping. Additionally, by using this mechanism, the process becomes smoother and more efficient, ensuring a seamless operation throughout. Moreover, the belt mechanism enhances performance by eliminating interruptions, which contributes to a more reliable and precise functionality.

Easy to use

Basic settings and adjustments can be made using the switches and volume controls on the front panel, eliminating the need for cumbersome UP/DOWN key operations or a computer.

Easy setup and easy monitoring

By using the data setter (OPX-2A) or support software (MEXE02) sold separately, you can change parameters, set functions, and perform various monitors to better suit your system.

Operation status waveform monitor*

* Support software (MEXE02) is required to monitor the operating status waveform.

4 Control Modes

It can be operated in four control modes. In addition, by using the data setter (OPX-2A) or support software (MEXE02) sold separately, the functions of each control mode can be expanded.

Geared motor lineup

We offer four sizes of geared motors with mounting dimensions from 60 to 104 mm in combination with drivers.

Line up

| type | Rated power [W] | Mounting angle dimensions [mm] | Reduction ratio | Rated torque [N・m] | Instantaneous maximum torque [N・m] | Backlash [arcmin] | Electromagnetic brake | |

|---|---|---|---|---|---|---|---|---|

| Yes | none | |||||||

| standard | 50 | 42 | – | 0.159 | 0.478 | – | ○ | ○ |

| 100 | 0.318 | 0.955 | ○ | ○ | ||||

| 200 | 60 | 0.637 | 1.91 | ○ | ○ | |||

| 400 | 1.27 | 3.82 | ○ | ○ | ||||

| 750 | 85 | 2.39 | 7.16 | ○ | ○ | |||

| PS Geared | 50 | 60 | 1:5, 1:10, 1:25 | 0.716 to 3.22 | 2.15 to 9.66 | 15 or less | ○ | ○ |

| 100 | 1.43 to 6.44 | 4.29~19.3 | ○ | ○ | ||||

| 200 | 90 | 2.87 to 12.9 | 8.6–38.7 | ○ | ○ | |||

| 400 | 5.72 to 25.7 | 17.1 to 77.2 | ○ | ○ | ||||

Related Products

-

KORI SEIKI BEP Length Measurement Transmitter (Pulse Transmitter)

-

TONE GPAL-175 Auto Grip Pliers (Long Nose Type)

-

KETT ELECTRIC LABORATORY MT-900 Wood Moisture Tester

-

SAKUSAKU 2SSB-R10 Carbide Ball End Mill 2-Flute

-

YOSHITAKE GD-200C-N Pressure Reducing Valve – Water · Oil · Air

-

Organo D-4 K50 Filters