Japan, Orientalmotor

Orientalmotor US2 Series AC Speed Control Motors

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: US2 Series

Overview of US2 Series

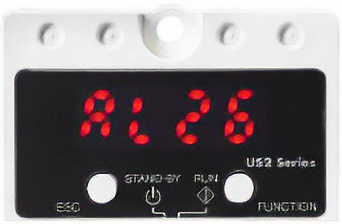

Easy Operation

The digital display panel and setting dials allow for intuitive operation.

It is so simple to use that anyone can master it without looking at the manual.

Simple and Intuitive Operation

Turn the setting dial to set the desired value. Determine the rotation speed by simply pushing the setting dial.

Start, Stop, and Change of Rotation Direction

With single switch operation, start, stop, and change the rotation direction. There is no need to install an external switch.

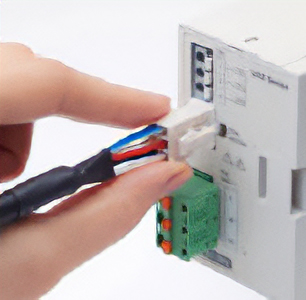

Simple Wiring

Just connect the motor and speed controller, connect to the power supply to start up immediately.

The speed controller has connectors and a built-in capacitor, which eliminates troublesome wiring and connections.

Maximum Extension Distance 10 m

Easy connection between motor and speed controller via connector.

Extend the connection between the motor and speed controller up to 10 meters for greater flexibility.

Built-In Capacitor

The built-in capacitor reduces the need for wiring, and saves space.

High Reliability

Low Noise and Simple System Configuration

The motors and speed controllers used in the US2 Series generate almost no noise.

Therefore, you need fewer noise-suppressing accessories, which simplifies installation, reduces costs, and saves space.

Speed Control Using Closed Loop Control

Stable Operation Even When Load Fluctuates

Thus, requiring fewer noise-suppressing accessories makes installation easier, lowers expenses, and conserves space. In addition, the digitalization of the control circuit has improved the speed regulation from -5 % to ±1 % (reference value).

Useful Functions

Open the Front Panel to Set Various Functions

- Digital Display

Monitoring information and alarm codes can be displayed. - Equipped With Indicator

Configure to display either the gearhead output shaft rotation speed or the conveyor transfer speed. - Operation Method Selection

Select whether to operate by the switch on the front panel or by external commands. - Data Protection (Lock)

Lock the data setting so that the set rotation speed cannot be changed.

Smooth Operation When Starting and Stopping

Adjust motor acceleration time using the acceleration/deceleration time potentiometer.

Setting time 0.1~15 seconds (Factory Setting: Fixed at 1 second)

Protection of Motor and Speed Controller

Protects the motor and speed controller with an alarm display if motor generates abnormal heat, has a poor connection, or locks up.

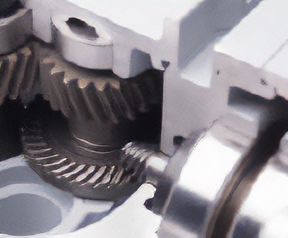

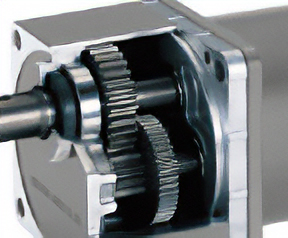

Both right-angle and parallel shafts utilize high-strength gears.

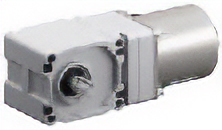

Use of a High Permissible Torque, High Strength Gearhead

Uses a motor and gearhead that excels in both permissible torque and strength.

Right-Angle Hollow Shaft Hypoid JH Gearhead

High strength hypoid gears are used. Significant torque enhancement and noise reduction compared to conventional products are achieved.

The radial and axial loads on the gearhead output shaft are also greatly increased, contributing to the downsizing and enhanced reliability of the equipment.

Parallel Shaft Gearhead GV Gearhead

By increasing the size of the output shaft bearing and using carburized gears, the permissible torque and permissible radial and axial loads have been increased compared to the conventional gearhead.

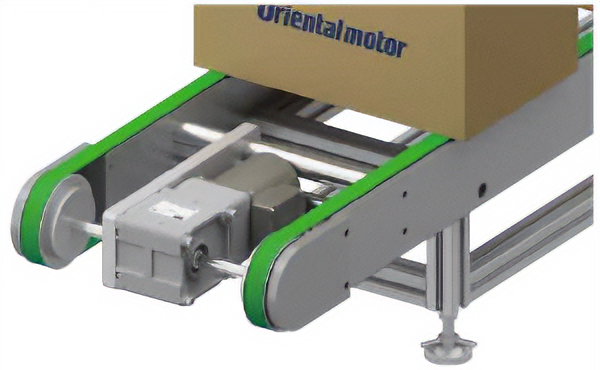

Space Saving and Cost Reduction

Right-Angle Hollow Shaft Hypoid JH Gearhead/Right-Angle Solid Shaft Hypoid JL Gearhead

Motor Mounted Perpendicularly to Drive Shaft for Space Saving

Cost Reduction by Directly Linking to the Drive Shaft

Installation Inside the Conveyor Saves Even More Space

Conveyor drive rollers can be installed on both ends of the load shaft of a hollow shaft type.

The equipment can be made even smaller compared to when the motor is installed on the side of the conveyor.

Easy Installation With Torque Arm

The torque arm (sold separately) further reduces installation time and effort. (Hollow shaft type)

Easily centered with the equipment

Only one needed to stop rotation and secure the equipment

Product Line

The “motor,” “speed controller,” and “connection cable” are arranged separately. They can be purchased in various combinations.

(When the screen transitions upon selecting motor type, the product names of the motor, speed controller, and connection cable, each associated with a “+,” will be displayed as a candidate.)

Parallel Shaft Gearhead GV Gearhead and Round Shaft Type

| Combination Motor | Voltage [V] | Upper Row: Motor Frame Size/Lower Row: Output Power | ||||||

|---|---|---|---|---|---|---|---|---|

| 60 mm | 70 mm | 80 mm | 90 mm | |||||

| 6 W | 15 W | 25 W | 40 W | 60 W | 90 W | |||

| Parallel Shaft Gearhead GV Gearhead | Single-Phase 100 Single-Phase 110/115 Single-Phase 200 Single-Phase 220/230 | ● | ● | ● | ● | ● | ● |

| Round Shaft Type | |||||||

Right-Angle Hypoid Gearheads

| Combination Motor | Voltage [V] | Upper Row: Motor Frame Size/Lower Row: Output Power | ||||||

|---|---|---|---|---|---|---|---|---|

| 60 mm | 70 mm | 80 mm | 90 mm | |||||

| 6 W | 15 W | 25 W | 40 W | 60 W | 90 W | |||

| Hollow right-angle shaft hypoid JH gearhead | Single-Phase 100 Single-Phase 110/115 Single-Phase 200 Single-Phase 220/230 | – | – | ● | ● | – | ● |

| Right-angle solid shaft hypoid JL gearhead | |||||||