Japan, Satuma Denki

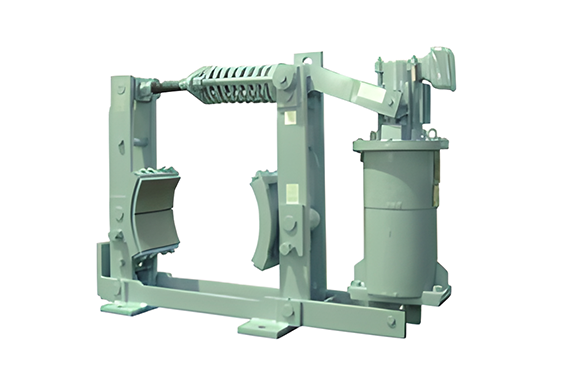

Satuma Denki BMS5-T, BMS5-WT Lifter Brakes MEW

Made in Japan

Manufacturer : Satuma

Model : BMS5-T, BMS5-WT

The MEW Lifter brake uses a MEW Lifter (trade name of an electro-hydraulic lifter) instead of the electromagnet used by an electromagnetic brake. The MEW Lifter characteristics mean a slower operation with less impact than electromagnetic brakes. To further decrease the operational speed, type BMS5- WT decreases the braking torque, and uses a MEW Lifter equipped with a lowering time-adjustment mechanism, which is ideal for traversing and traveling of cranes and stopping of conveyers.

Types and Ratings of Drum Type Brakes

| Brake Type | BMS5-T type MEW Lifter brakes & BMS5-WT type MEW Lifter brakes |

| Applicable standard | JEM 1240 (AC. operated brakes for totally-enclosed fan-cooled low-voltage three-phase wound-rotor induction motor for crane use) |

| Actuation | No-voltage operation |

| Application | For traversing and traveling of cranes, for conveyers |

| Ambient temperature | -10°c ~ + 40°c |

| Protective structure of operation unit | Dustproof type (Main unit: Unprotected type) |

| Insulation class of operation unit | Class E insulation |

| Rated voltage and frequency | 400V 50Hz、440V 60Hz |

| Usage rate of operation unit | 60% |

| Actuating cycle | 400 (cycle/hour) BMS5-2840 (W) T or smaller, 250 (cycle/hour) BMS5-3145 (W) T or larger |

| Coating color | Munsell 5B5/ 0.5 |

Application of Drum Type Brakes to motors

| Motor | AC-operated DC electromagnetic brakes and MEW Lifter brakes | |||||||

| Frame No. |

Number of poles |

Type of MEW Lifter brake | Motor output and rated braking torque | |||||

| 25%ED | 40%ED | 60%ED | ||||||

| Motor output

(kW) |

Rated braking torque(N·m) | Motor output(kW) | Rated braking torque (N·m) | Motor output

(kW) |

Rated braking torque (N·m) | |||

|

132M |

6 |

BMS5-1316T | 2.5 | 49 | 2. 2 | 49 | 1.8 | 49 |

| 4 | 66 | 3 . 7 | 66 | 3 | 49 | |||

|

160M |

6 |

BMS 5-1620T- 1 | 6.3 | 98 | 5.5 | 98 | 4. 5/6. 3 | 98 |

| BMS5-1620T-2 | 8.5 | 137 | 7 . 5 | 137 | — | — | ||

| 160 L | 6 | BMS5-1620T- 2 | 13 | 208 | 11 | 208 | 9 | 137 |

| 180 L | 6 | BMS5-1825T | 17 | 294 | 15 | 294 | 13 | 208 |

| 200 L | 6 | BMS5-2025T | 392 | 22 | 392 | 18.5 | 294 | |

| 225M | 6 | BMS5 – 2231T | 33 | 519 | 30 | 519 | 25 | 392 |

|

250M |

6 |

BMS5- 2535TB | 40 | 617 | 37 | 617 | 30 | 519 |

| 50 | 784 | 45 | 784 | 37 | 617 | |||

| 280M | 8 | BMS5 – 2840T | 63 | 1290 | 55 | 1290 | 45 | 980 |

|

315M |

8 |

BMS5- 3145T |

85 | 1760 | 75 | 1760 | 63 | 1290 |

| 100 | 2080 | 90 | 1760 | 75 | 1760 | |||

|

355L |

10 |

BMS5- 3550T |

125 | 3280 | 110 | 3280 | 90 | 2600 |

| — | – – | 132 | 3280 | 110 | 3280 | |||

| 150 | 3920 | –·- | — | — | — | |||

|

400 L |

10 |

BMS5- 4056T |

185 | 4660 | 160 | 3920 | 132 | 3920 |

| — | — | –·- | — | 160 | 3920 | |||

| 220 | 5490 | 200 | 5490 | — | — | |||

Feature

1. A brake lining with a contact angle of 60° is adopted.

・Excellent initial braking torque characteristics and easy replacement

2. Automatic vertical gap adjustment of brake lining

・Simple maintenance and inspection

3. Can be manually opened

・This no-voltage actuation bake can be manually opened using a special auxiliary nut (bolt.)

4. Large electromagnetic brakes come with an air damper (which can be optionally mounted to other electromagnetic brakes. Please refer to the note column of each specification/external dimension table for the standard equipment scope.)

・Mounting the air damper helps ensure shockless and low-noise operation

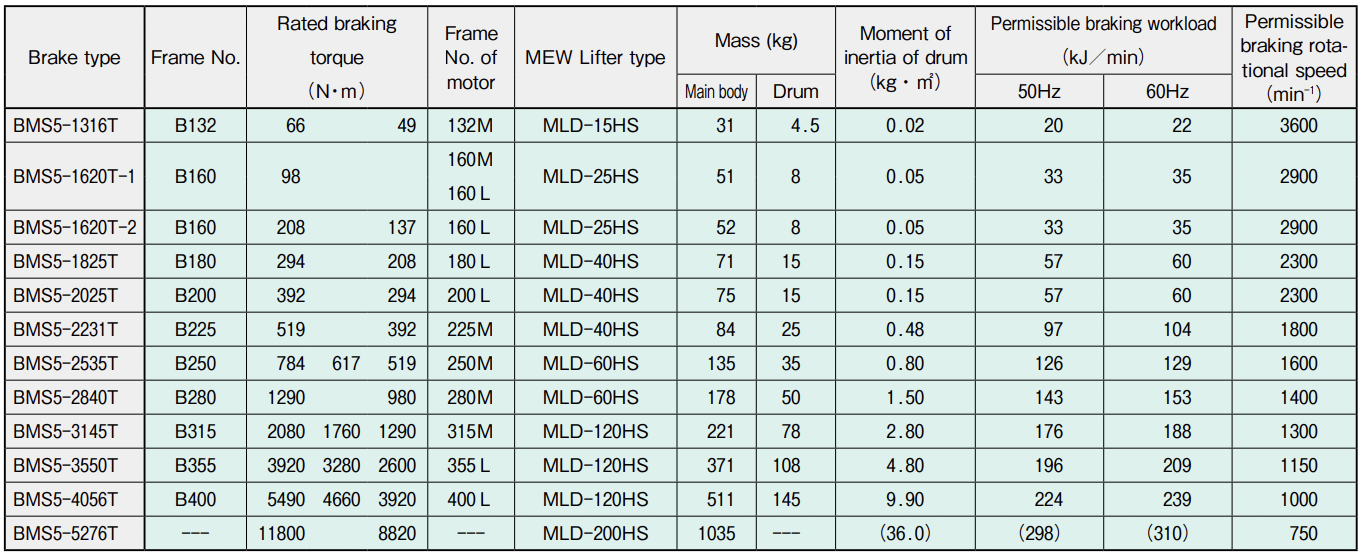

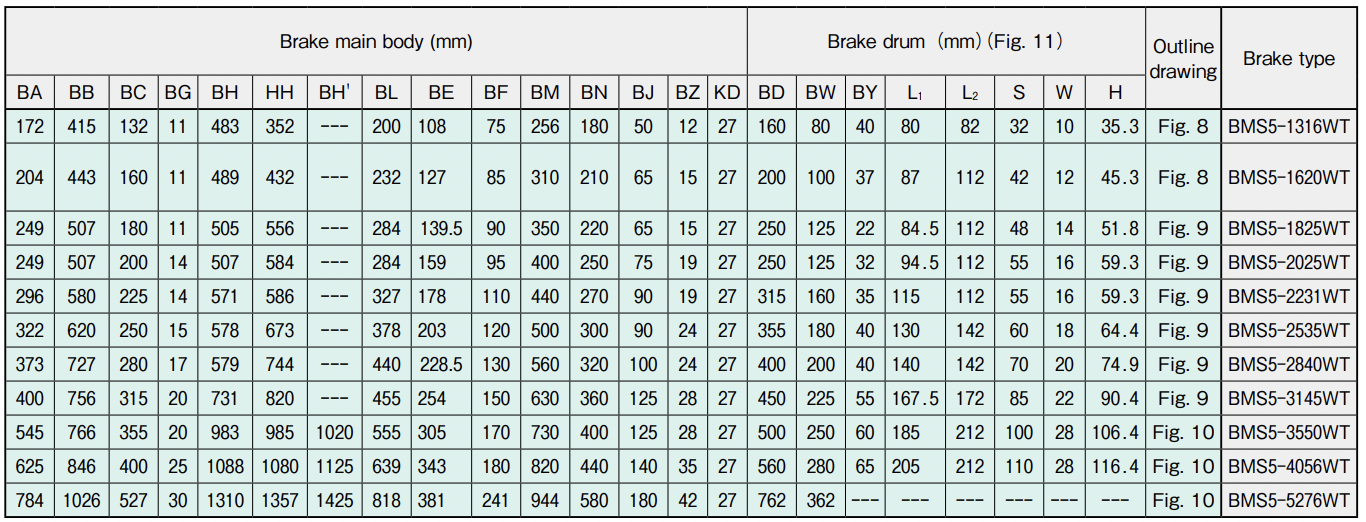

Specifications and external dimensions of BMS5-T Type MEW Lifter brakes

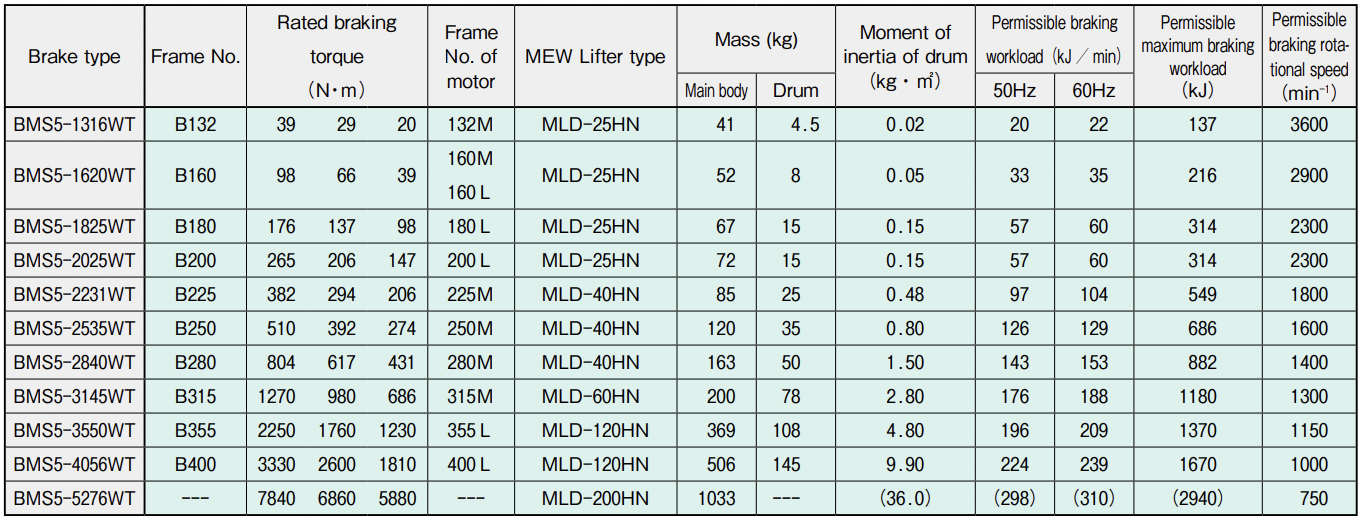

Specifications and external dimensions of BMS5-WT Type MEW Lifter brakes

Note 1: See Table 1 (P.1 and 2) for major ratings.

Note 1: See Table 1 (P.1 and 2) for major ratings.

Note 2: Shared use for 200 V and 400 V is possible by changing the connection of the MEW Lifter, but shared use for 50- and 60-Hz frequencies is not allowed.

Note 3: MLD-15HS (used for BMS5-1316T) is exclusive for each voltage and frequency.

Note 4: The moment of inertia and each braking workload of the brake drum for BMS5-5276 (W)T are for your reference.

Note 5: Contact us when using the brake for crane hoisting. Some brakes are not appropriate for this purpose.

Fig. 10 BMS5-3550(W)T〜5276(W)T

Note 6 : The brake drum (Fig. 11) is made of gray cast iron (FC250.)