Japan, Showa Sokki

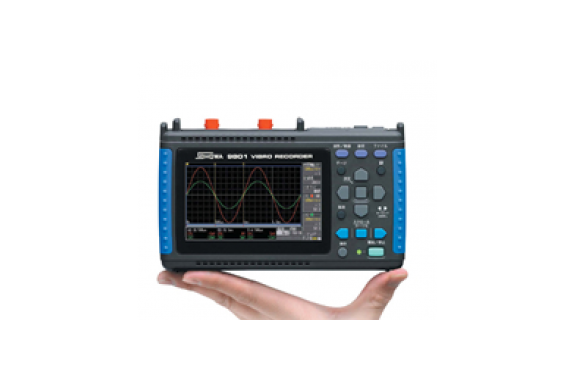

SHOWA SOKKI 9801 Vibration waveform recorder Vibro recorder

Made in Japan

Manufacturer: SHOWA SOKKI

Model: 9801

Features

Smaller and easier to use. Perfect for recording vibrations!

・You can easily record waveforms by connecting to a vibration meter.

・It records to a CF card and can transfer to a PC.

・The system provides trigger and pre-trigger functions for recording impact waveforms.

・You can record voltage signals like vibration waveforms, with a maximum sampling rate of 400 kHz.

. You can perform frequency analysis using FFT analysis software (option).

. You can select high-speed recording and long-time recording by switching the sampling time.

- This is a compact recorder with a 4.3-inch TFT color liquid crystal display. The main body weighs about 600g, making it lightweight and easy to carry.

- It is suitable for combination with our portable vibration meter and other vibration meters.

Application example

Optimal recorder/recorder for recording vibration waveforms

Waveforms of vibration spread over a wide range, from very low frequencies such as those of buildings and ground to high frequencies such as those of high-speed spindles. MODEL-9801 is a recorder that can handle those wide bands. Furthermore, it efficiently records signals only when abnormal vibrations occur due to its trigger function.

■ Vibration of rotating machines such as motor pumps

Display an example of a blower vibration waveform in displacement mode.

You can change the time axis and voltage axis so that the vibration waveform is easy to see. It is easy to operate because you can change while checking the waveform.

■ High-frequency vibration such as abnormal bearings

Example of displaying vibration waveform with higher frequency in acceleration mode

The high-resolution TFT LCD display is very clean, allowing for precise observation of even fine waveforms. You can easily save waveforms by pressing the save button at the bottom right of the screen.

■ Acceleration waveform of drop impact.

Example of displaying the drop impact as an acceleration waveform.

This screen records the impact of packaging and the dropping of a digital camera. By setting the trigger, it captures the shock waveform at a fixed position on the screen.

Recording only when abnormal vibration occurs/Recording using trigger/pre-trigger.

Using the trigger function initiates recording when the system receives a signal with a preset level. Therefore, even if you wait for a long time, it will not waste memory.

You can put the recorder on standby and record only when abnormal vibration occurs.

You can also record the signal before applying the trigger using the pre-trigger function. This is useful for recording impacts.

The waveform below records the impact. There is a [T] mark on the left side of the upper part, but that’s when the trigger worked.

In the waveform below, we recorded the time 40ms before the trigger and 160ms after the trigger.

You can see that we efficiently recorded only the time before and after the moment the impact worked.

Display waveforms on a computer. Do a frequency analysis.

By using the wave processor that comes with the Vibro Recorder MODEL-9801, you can observe the waveforms recorded by the recorder on your computer.

The wave processor has the following features.

・Application software that realizes waveform display and CSV text conversion on a personal computer.

・XY display is possible.

・There are graphic input, comment input and template functions that support report creation.

・Multiple files can be converted to CSV data at once.

Specification

| basic specifications | |

|---|---|

| Measurement function Input method/number of channels |

Memory recorder, recorder. 2 channels. |

| Maximum sampling speed | 1M Sample/s (1μ, all channels simultaneously). |

| Memory capacity | 12bit×2M word/CH. |

| Backup function | Clock, setting conditions, waveform data. |

| External control terminal | Terminal block, external trigger input, trigger input/output. |

| Interface | USB: UB2.0 compliant, HighSpeed compatible. Function: Connect to PC and transfer CF card files to PC. |

| Environmental conditions (no condensation) | Operating temperature and humidity range: 0 to 40°C, 80% RH or less. Storage temperature and humidity range: -10 to 50°C, 80% RH or less. |

| Power consumption | AC adapter 9786: 100 to 240 VAC (50/60 Hz). battery pack 9780: Continuous operating time: about 2 hours. 12 VDC system: 10 to 16 VDC (connection cable is made-to-order). |

| Compliant standard | Safety: EN61010. EMC: EN61326, EN61000_3_2, EN61000_3_3. |

| Charging time (9780) | 200 minutes (reference value at 25°C) using AC adapter 9786. |

| External dimensions/mass | Dimensions: Approx. 176W x 101H x 41Dmm. Weight: Approx. 600g (with battery pack 9780 installed). |

| Accessories | AC adapter 9786, strap, USB cable, application disk (for wave processor 9801), instruction manual. |

| Input section (accuracy 23±5°C 80% RH or less, specified 30 minutes after power-on, accuracy guaranteed for 1 year) | |

| input terminal | Insulated BNC terminal. |

| Measuring range | 10mV to 50V/DIV, 12 ranges, full scale (FS): 10 DIV. low-pass filter: 5/50/500/5kHz. |

| Accuracy, frequency characteristics | DC Amplitude: ±0.5%FS DC to 50kHz-3dB. |

| Input resistance, capacitance | Input resistance: 1MΩ, Input capacitance: 7pF. |

| Input coupling | DC/GND. |

| Maximum input voltage | 400 VDC (maximum voltage that can be applied between input terminals without damage). |

| Maximum rated voltage to ground | AC, DC 300V CATII. |

| Memory recorder function | |

| Time axis | 100 μs to 5 min/DIV 20 ranges, time axis resolution: 100 points. /DIV, time axis expansion: x2 to x10, compression 1/2 to 1/1,000. |

| Sampling period | 1/100 of the time axis range (maximum 1 μs cycle, all channels simultaneously). |

| Record length | 10 steps from 20 to 20,000 DIV (In the case of continuous, there is a limit on the time axis). |

| Pre-trigger | Recording before trigger is possible, 0 to 100% of recording length. |

| Others | Expansion of voltage axis x2 to x10, compression (1/2, 1/5). |

| External memory | Setting conditions, measurement data (text and binary), screen data. |

| Screen copy | Saves the display screen of the main unit to a CF card in compressed bitmap format. |

| Scaling | Input values can be converted from voltage to physical quantities such as acceleration. |

| Auto save | Possible. |

| Waveform monitor | Settings can be made while monitoring the waveform on the waveform screen. |

| Record display | |

| Display body | 4.3-inch WQVGA-TFT color LCD (480 x 272 dots). |

| Display resolution | Waveform part: 20DIV (time axis) x 10DIV (voltage axis). 1DIV = 20dot x 20dot. |

| Trigger function | |

| Trigger mode | single, continuous. |

| Trigger source | Analog input 2ch, external trigger (falling edge of 2.5V or terminal short), ON/OFF for each source. |

| Trigger type | Level: Rise or fall of the set voltage. Window trigger: When the level enters or exits the upper or lower limit. |

| Other functions | Pre-trigger function to capture before and after trigger, trigger output. |

| Wave processor (software specification supplied with 9801) | |

| Operating environment | PC that can run Windows 2000, XP, Vista (32bit version) (*2). |

| File read | Waveform data saved by 9801 (binary format, extension MEM). |

| Slide display | Waveform files in the same folder can be displayed in order. |

| Text conversion | Data conversion format: CSV, data thinning possible. |

- Kouei is Distributor/Agent of SHOWA SOKKI

- Other items of SHOWA SOKKI

- Request the quotation for SHOWA SOKKI