Drilling And Cutting, Japan, Sumitomo Denko

Sumitomo Strong MultiDrill HX / HY – High Efficiency Solid Carbide Drills

Product Made in Japan

Manufacturer: Sumitomo

Model: HX / HY

Covers a wide range of cutting conditions for cast iron drilling. Easy-to-use and improved efficiency.

Product Video

Features

Model HX

Strong MultiDrill HX series is a special drill for cast iron which combines reduced cutting force and improved drill strength to achieve stable and high efficiency drilling.

For high-efficiency machining of cast iron

Utilizing a thick core with a special double margin design to ensure stable behavior even in high-efficiency drilling applications.

In addition, “RX-thinning” is used to significantly reduce cutting force to achieve high-efficiency drilling with more stability (for ø10mm drills) and also allowing high-efficiency drilling of more than vf=1,000mm/min.

Long tool life

“DEX Coat” exclusively for drills, utilizes nano-coating technology to achieve more than double the tool life of conventional coatings. Enhanced guiding function through optimizing margin positions, prevents breakage due to hole bending.

Model HY

Strong MultiDrill HY series is a 3-fluted drill that achieves stable, high efficiency drilling of steel and cast iron, reducing load placed on each cutting edge and ensuring long tool life.

For high-efficiency drilling of steel and cast iron

Utilizing a thick core with a 3-point margin design to achieve high-efficiency drilling with stable hole accuracy.

In addition, “RY-thinning” is used to achieve high-efficiency drilling with reduced cutting force and is applicable to cutting conditions of more than vf=800mm/min for steel and more than vf=1,000mm/min for cast iron (for ø10mm drills).

Long tool life

“DEX Coat” exclusively for drills, utilizes nano-coating technology to achieve more than double the tool life of conventional coatings.

High-level guiding functions with a 3-point margin design achieve stable and long tool life with minimized vibration

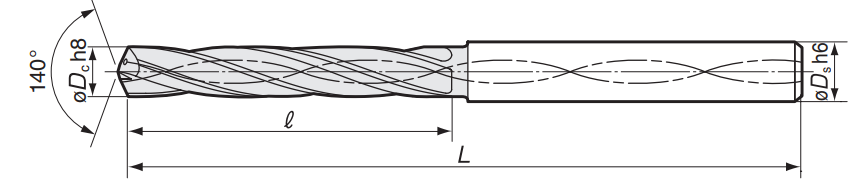

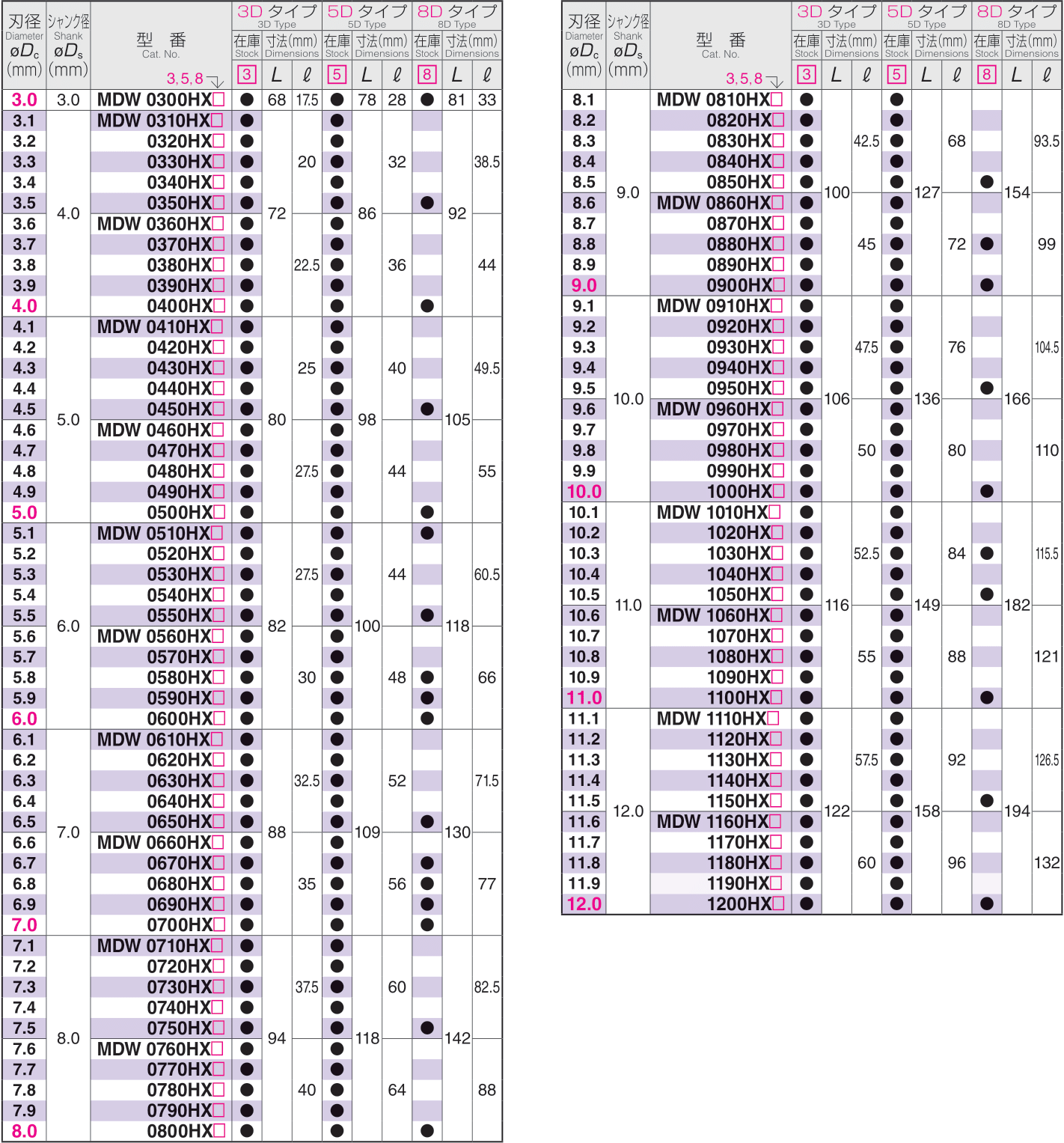

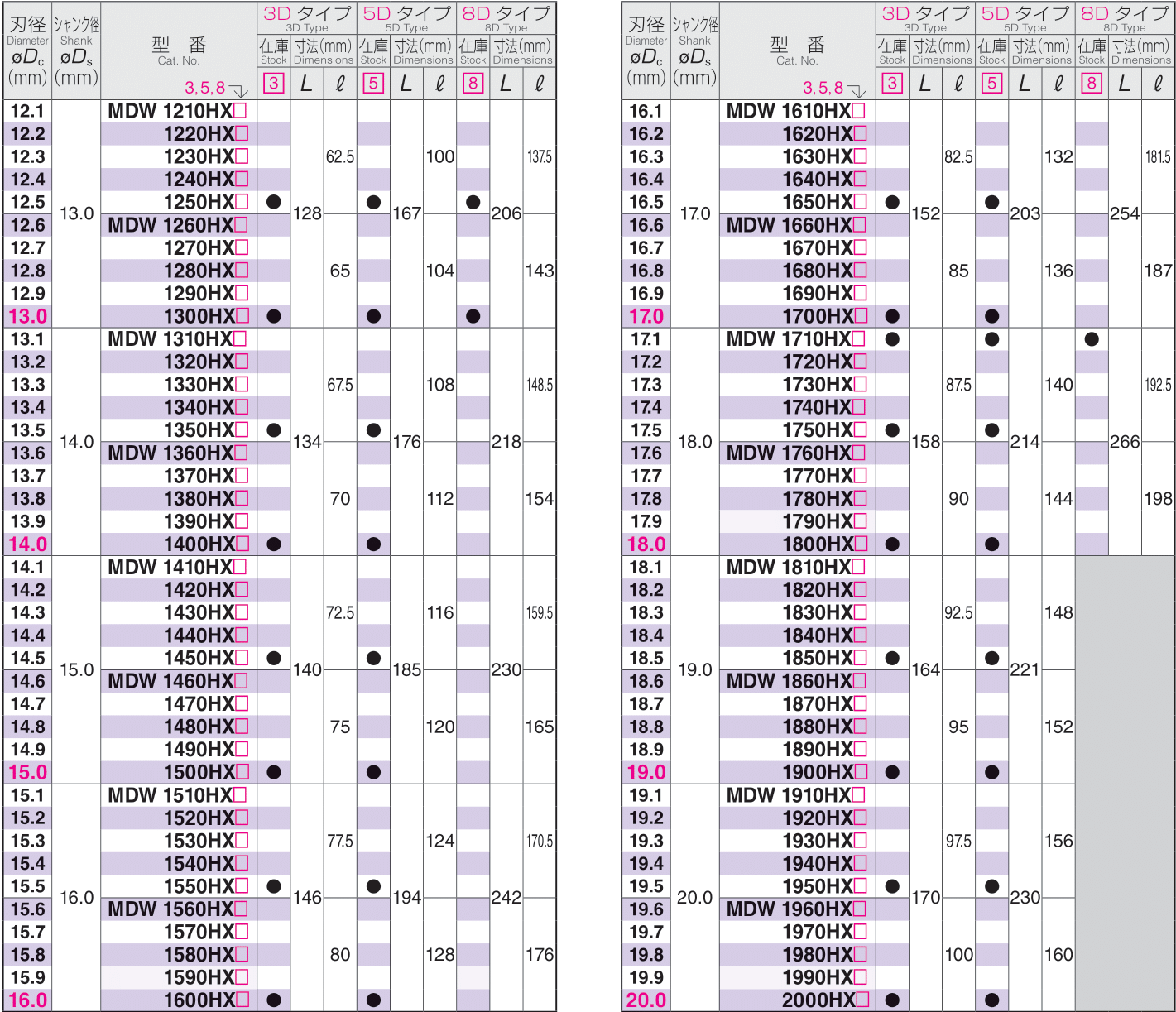

Specification

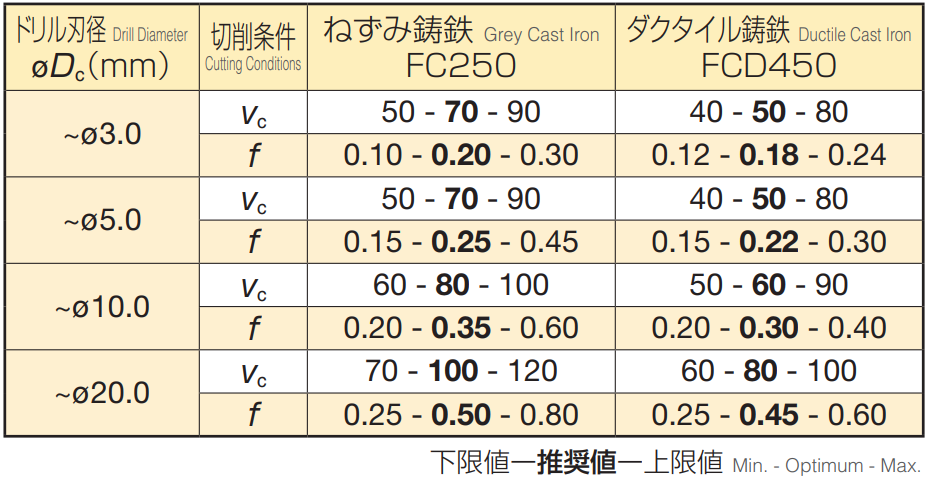

HX

Recommended Cutting Conditions

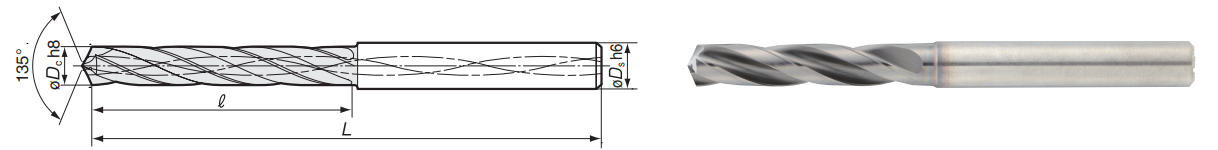

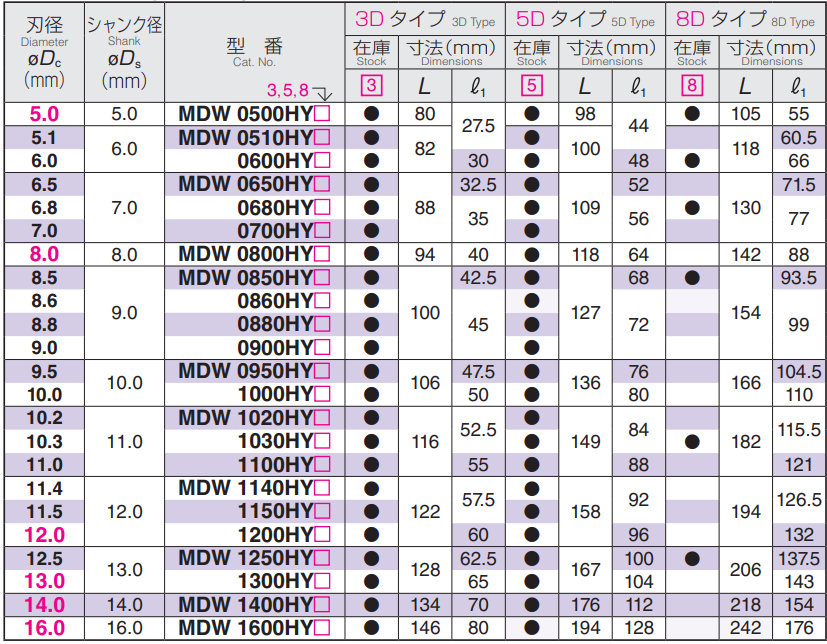

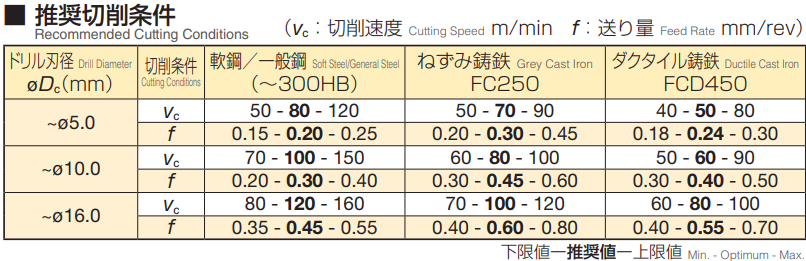

HY

Recommended Cutting Conditions

Related Products

-

Ross Asia Medium series Port size is 1/4″ to 1/2″. Flow rates up to 100 scfm (2832 l/min)

-

TONE CS100 Combination Wrench Set

-

SENSEZ MJI Terminal Box-type Pressure Sensors

-

Super Tool GWS250H Water Pump Pliers (Spring Type)

-

Yutani Impact Wrench (Straight Type)

-

Vessel No.SH-60 Compact AC Pulse Ionizing Bar (separate power supply type)