Japan, Sam Steel Checker, Tachibana Eletech

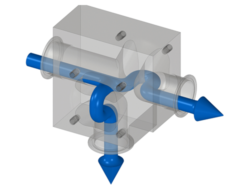

Tachibana Eletech D-200 Sam Steel Checker

Product Made in Japan

Manufacturer: Tachibana Eletech

Model: D-200

Advantages

- Non-destructive measurement

- Portable

- No need for skill to use (only about 5 seconds per measurement)

Applications

– Checking whether the current product of steel is the same as the standard.

– Confirming whether the cut steel sheet is the same material as the cut surface or not.

– Classifying steel materials with different materials.

– Estimating steel with unknown material.

Precautions before use

– Remove black skin and rust on the surface of steel material.

– Wipe off the water in the measurement area.

– Only use when there is no AC current flows through the steel material.

– Ensure the temperature of steel material is 5C ~ 35C.

– The average value of the same part measured three or more times.

– The thickness of the steel material in the measurement part should be 2 mm or more.

– Avoid the part that is rapidly cooled.

– Use the probe carefully and be careful not to damage the sensor needle.

Specifications

| Display method | Digital display type |

|---|---|

| External dimensions | 140X200X60 (mm) (body dimensions) |

| Weight | Approximately 2.4 kg (main unit and probe) |

| Power supply | Built-in battery |

| Specification temperature range | 0 ℃ ~ + 40 ℃ |

| Measured steel temperature | 5 ℃ ~ + 35 ℃ |

| Storage temperature range | -10 ℃ ~ + 50 ℃ |

| Humidity | 80% RH or less |

| Number of continuous measurements | 300 times for 5 seconds |

| Measurable range | Various steel materials and alloys from mild steel to stainless steel |

| component | Main unit, probe, battery (built-in main unit), cable (for probe, AC power supply, DC power supply), carrying case, dedicated charger, standard sample (2 types), stick file, sandpaper. |

Related Products

-

Saitamaseiki AK-1102CL Grinders and single action sanders

-

UNIKA SDS MAX Type SDS-Max Bit

-

TONE 571, 572 Ratchet Handle & Ratchet Head

-

Nakatani Kikai NAS7B‐CR Angle Grinder (Diamond Cutter, 7 Inch Type)

-

Nippon Daiya Valve Sampling Valve Dead Space Countermeasure Products

-

Organo ORPERSION E400 Slime Control Agent for RO Membranes