Bolt & Nut, Japan, Takenaka Seisakusho

Takenaka Seisakusho NANOTECT® Coating Bolt

Import from: Japan

Manufacturer: Takenaka Seisakusho

Super-hard, Anticorrosive, CNT-Composited Coating “NANOTECT®”

Features

Abrasion Resistance: NANOTECT® has excellent resistance againtst wear and abrasion.

Impact Resistance: NANOTECT® has the highest impact resistance of all resin coatings.

Bending Resistance: NANOTECT® has very high bending resistance.

Bending resistance: NANOTECT® has very high bending resistance.

Film Hardness: NANOTECT® film is almost as hard as metal coatings.

Lubrication: NANOTECT® has very high lubrication performance like PTFE coating.

Anti Corrosion: NANOTECT® has excellent corrosion resistance with the electric conductivity of CNT insulated by our unique technology of surface grafting.

Treating process

Surface treatment using carbon nanotubes, a world-first new dream material

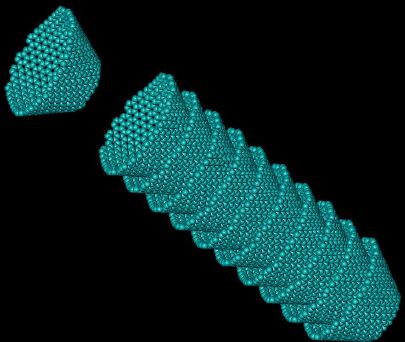

Image of Cup-Stacked-type Carbon Nanotube (CSCNT) provided by GSI Creos Corp., Japan

World’s first uniformly dispersed carbon nanotubes

Carbon nanotubes have several times the tensile strength of steel and have high conductivity: they are a next-generation carbon material. Without being mixed with resin, the conductivity of the carbon nanotube materials cause corrosion, so they were not suitable as a coating for anti-corrosion purposes, however, Takenaka’s unique technology called “grafting” successfully blocks the conductivity and disperses the carbon nanotubes uniformly and at high density. The result has been a fusion of the strength of carbon nanotubes with Takenaka’s anticorrosion technology to create surface treatment, NANOTECT®.

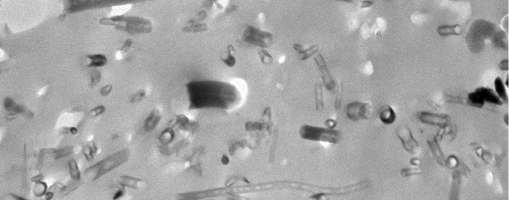

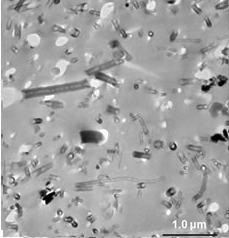

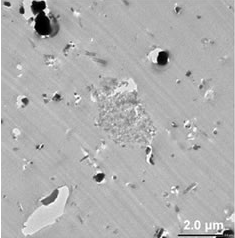

Dispersion effect of Carbon Nanotube on solvent

Comparison of dispersion state of Carbon Nanotube in resin

grafted Carbon Nanotube (NANOTECT®)

Not grafted Carbon Nanotube

Related Products

-

KONAN MB2 Tank Bottom Sanitary Valves Manually-operated

-

KGK UX/UM/UA Ultra-Miniature Angle Probe

-

Daitoukeiki CP-3 Desktop reference dead weight pressure guage(High pressure)

-

Takeda Machinery ABM-1015/1530/1540G Drilling Machine

-

NAGANO KEIKI CS41 Pressure Switch

-

Furuto Industrial (Monf) No.601 OPP Adhesive Tape