Bolt & Nut, Japan, Takenaka Seisakusho

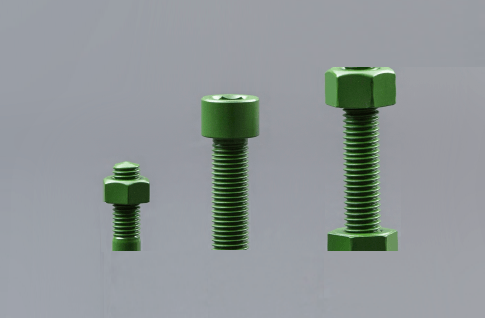

Takenaka Seisakusho TAKECOAT®-1000 Coating Bolt

Import from: Japan

Manufacturer: Takenaka Seisakusho

TAKECOAT®-1000 Surface Treatment

Fluorocarbon polymer coating in the world’s top shareTAKECOAT®-1000 saves your plants from corrosion in a corrosive area such as sea and desert area etc.

- TAKECOAT®-1000 is an astounding surface treatment with approximately 6-times the durability of hot-dip galvanizing as shown in salt spray testing to evaluate rust resistance. TAKECOAT®-1000 protects metal products from rust and extends their life in various corrosive environments.

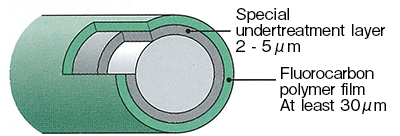

- TAKECOAT® -1000 has a two-layer structure of special fluorocarbon polymer film and special under-treatment layer. Combined with a special treatment technology, the film is thin but is excellent in corrosion resistance and durability. The surface has a high lubricity.So, TAKECOAT®-1000 has the most suitable coating propaties for fasteners. This product has been used in structures and environment requiring corrosion resistance for a long period, including fastening bolts and metal parts for bridges, underground segments, buried pipes, marine structures, petroleum plants etc.

Features

Resistance to rust and corrosion: TAKECOAT®-1000 showed astounding anti-rust performance of 6,000 hours (hot-dip galvanizing was approx. 1,000 hours) in salt spray testing measuring anti-rust and anticorrosion performance. The superiority of that performance has also been affirmed from numerous outdoor exposure tests and usage results, on and under the sea, etc. Third-party organizations (Japan Quality Assurance Organization, US firm KTA Inc., etc.) have verified its superior performance in indoor accelerated corrosion tests.

Durability: Owing to high lubricity and hardness of fluorocarbon polymer film, the film is hardly damaged even when a high load or shearing force of a few 10 tons is applied on the film surface. Forming of rust from the damage portion is very rare. (Particularly effective for fastening of bolts). Stainless steel bolts are used with the aim of preventing seizing.

Heat resistance: Fluorocarbon polymer features excellent heat resistance and refrigerant resistance.Temperature of continuous use: -196°C to +200°CTemperature of intermittent use: -196·C to +230·C

Insulation: The film of fluorocarbon polymer is very thin and rigid, and is almost free from pin hole. Hence, it is effective to prevent (crevice corrosion),(galvanic corrosion),(pitting corrosion), etc. When steel bolts treated with TAKECOAT®-1000 are used to fasten stainless steel flanges, use plain washers treated with TAKECOAT®-1000 without fail.* For insulation in high voltage atmosphere, ELE CUT is recommended.

Stable fastening of bolts: In spite of fluorocarbon resin coating, it is excellent in lubricity, low in torque and unidorm making fastening of bolts is easier.

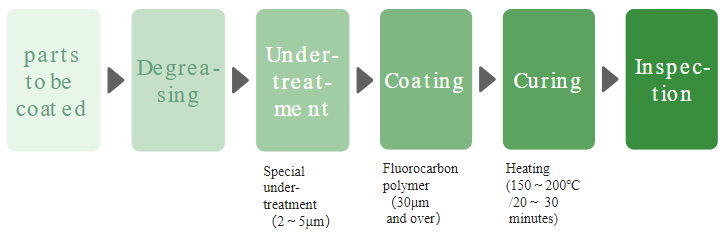

Treating process

By the manufacturing method of Takenaka’s original treatment technology, a thin and uniform film is formed.

There is no danger of hydrogen embrittlement because there is no pickling process.

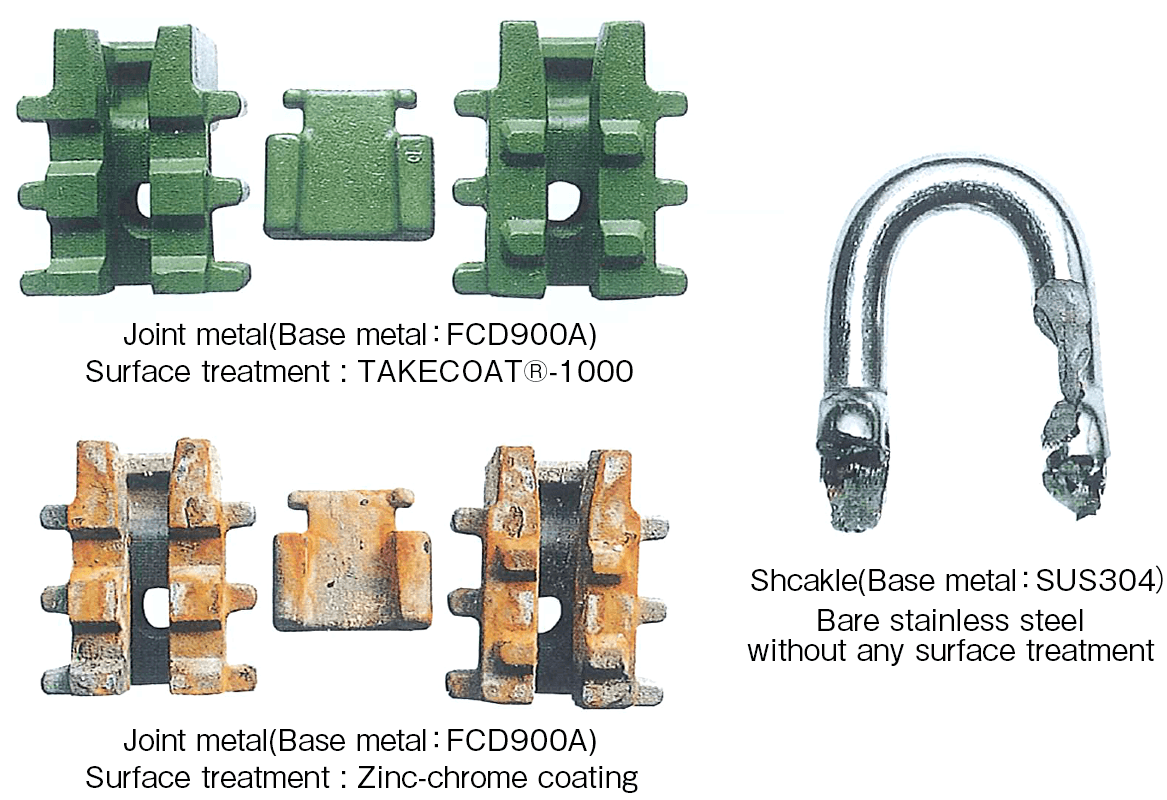

Durability in sea

Stainless steel corrodes in sea. Even in the such severe marine corrosive environments, TAKECOAT®-1000 protects metal from corrosion.

After 2 years of marine exposure test (Pacific Ocean coast, immersed in seawater)

Solt spray test