Taseto

TASETO GFW Series Flux Cored Wires

Product Made In Japan

Manufacturer: Maiko Shokai

Model: GFW Series

| Trade Name | Certification | |

|---|---|---|

| JIS | AWS | |

| GFW308 | JIS Z 3323 TS308-FB0 | AWS A5.22 E308T0-1 |

| GFW308H | JIS Z 3323 TS308H-BiF-FB0 | AWS A5.22 E308HT0-1 |

| GFW308L | JIS Z 3323 TS308L-FB0 | AWS A5.22 E308LT0-1 |

| GFW308LAP | JIS Z 3323 TS308L-FC1 | AWS A5.22 E308LT1-1 |

| GFW309 | JIS Z 3323 TS309-FB0 | AWS A5.22 E309T0-1 |

| GFW309L | JIS Z 3323 TS309L-FB0 | AWS A5.22 E309LT0-1 |

| GFW309LAP | JIS Z 3323 TS309L-FC1 | AWS A5.22 E309LT1-1 |

| GFW309Mo | JIS Z 3323 TS309Mo-FB0 | AWS A5.22 E309MoT0-1 |

| GFW309MoL | JIS Z 3323 TS309LMo-FB0 | AWS A5.22 E309LMoT0-1 |

| GFW309MoLAP | JIS Z 3323 TS309LMo-FC1 | AWS A5.22 E309LMoT1-1 |

| GFW310E | JIS Z 3323 TS310-FC0 | AWS A5.22 E310T0-1 |

| GFW312 | JIS Z 3323 TS312-FB0 | AWS A5.22 E312T0-1 |

| GFW316 | JIS Z 3323 TS316-FB0 | AWS A5.22 E316T0-1 |

| GFW316L | JIS Z 3323 TS316L-FB0 | AWS A5.22 E316LT0-1 |

| GFW316LAP | JIS Z 3323 TS316L-FC1 | AWS A5.22 E316LT1-1 |

| GFW317L | JIS Z 3323 TS317L-FC0 | AWS A5.22 E317LT0-1 |

| GFW347 | JIS Z 3323 TS347-FB0 | AWS A5.22 E347T0-1 |

| GFW347L | JIS Z 3323 TS347L-FB0 | AWS A5.22 E347T0-1 |

| GFW329J3L | JIS Z 3323 TS2209-FC0 | AWS A5.22 E2209T0-1 |

| GFW2594 | JJIS Z 3323 TS329J4L-FC0 | AWS A5.22 E2594T0-1 |

| GFW82 | – | AWS A5.34 TNi6082-04 |

| GFW625 | – | AWS A5.34 TNi6625-04 |

| GFWHsC276 | – | AWS A5.34 TNi6276-04 |

| GFWHsC-22 | – | AWS A5.34 TNi6022-04 |

Specification

GFW308

Applicable Specification

JIS Z 3323 TS308-FB0

AWSA5.22 E308T0-1/4

Applications and Characteristics

TASETO GFW308 is used for welding Type 304 stainless steel.

Chemical Composition of All Weld Metal (%)

| C | Si Mn | P | S | Ni | Cr | Mo | Cu | ||

|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.041 | 0.56 | 1.46 | 0.018 | 0.004 | 9.72 | 19.79 | 0.02 | 0.02 |

Ferrite Content of All Weld Metal

* Typical Ferrite Content: 8.9% (Schaeffler’s Diagram)

13.9FN (DeLong’s Diagram) 10% (Ferrite Scope)

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) |

|---|---|---|

| Typical 406 | 619 | 38.0 |

Sizes Available, Shielding Gas

| Size, | Shielding Gas |

|---|---|

| 1.2, | CO2 or Ar+20%CO2, 20L/min, |

| 1.6 | CO2 or Ar+20%CO2, 20Umin |

GFW308H

Applicable Specification

JIS Z 3323 TS308H BiF-FB0

AWS A5.22 E308HT0-1/4

Applications and Characteristics

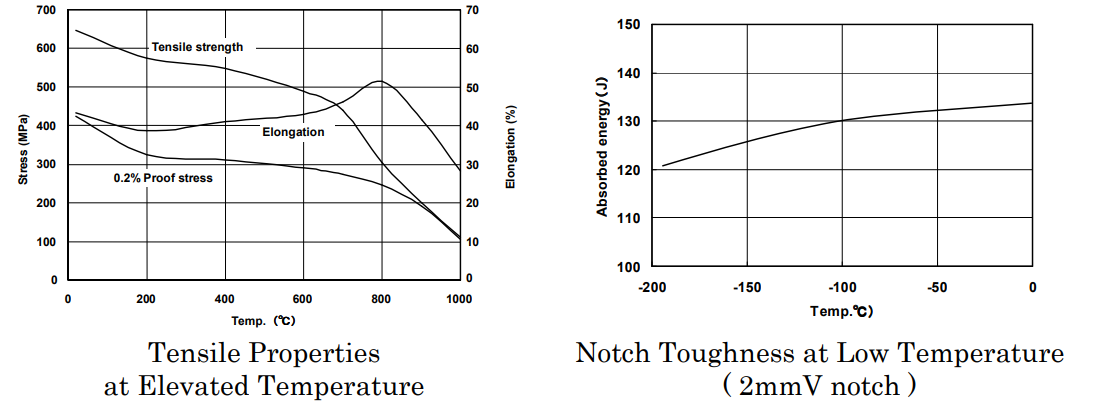

TASETO GFW308H is used for welding Type 304H for high-temperature service. As the ferrite content of welding metal is controlled to 3*8% in Schaeffler’s diagram, the mechanical properties of weld metal in elevated temperatures have been improved.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S Ni | Cr | Mo | Cu | ||

|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.045 | 0.45 | 1.43 | 0.022 | 0.005 | 9.88 | 19.22 | 0.02 | 0.02 |

Ferrite Content of All Weld Metal

* Typical Ferrite Content: 6.3% (Schaeffler’s Diagram)

7.1FN (DeLong’s Diagram)

6.4% (Ferrite Scope)

Mechanical Properties of All Weld Metal

| Test Temp. | 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) |

|---|---|---|---|

| Room Temp. | 404 | 617 | 43.0 |

| 300C | 319 | 453 | 27.1 |

| Typical 550C | 246 | 365 | 29.3 |

| 600C | 244 | 331 | 25.0 |

| 650C | 215 | 270 | 35.2 |

Creep Rupture

Test Temp. & Time Strength | |

|---|---|

| 550X: X 1000h | 240 MPa |

| 650X: X1000h | 127 MPa |

Absorbed Energy

| PWHT condition | Absorbed Energy |

|---|---|

| As welded | 75 J |

| 650C X l000h | 56 J |

| 750X:x 1000h | 52 J |

Sizes Available, Shielding Gas

| Size. | Shielding Gas |

|---|---|

| 1.2 | CO2 or Ar+20%CO2, 20L/min |

| 1.6 | CO2 or Ar+20%CO2, 20L/min |

GFW308L

Applications and Characteristics

TASETO GFW308L is used for welding of Type 304 and 304L stainless steel. Because of low carbon content, the resistance to intergranular corrosion is excellent and suitable for use in the case where solution heat treatment is impracticable.

Chemical Composition of All Weld Metal (%)

| C | Si Mn | P | S | Ni | Cr | Mo | Cu | ||

|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.026 | 0.39 | 1.55 | 0.018 | 0.003 | 10.19 | 19.86 | 0.02 | 0.02 |

Ferrite Content of All Weld Metal

* Typical Ferrite Content: 8.3% (Schaeffler’s Diagram). 11.4FN (DeLong’s Diagram). 9.0% (Ferrite Scope)

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | Absorbed Energy (J at -196X2) | |

|---|---|---|---|---|

| Typical | 352 | 543 | 44.0 | 32 |

● Corrosion Resistance of All Weld Metal

* Typical Corrosion Resistance 0.00076 in/month (0.22 g/m²・h)

(65%Nitric Acid Test)

180°bend without any defects

(Copper Sulfate-Sulfuric Acid Test: PWHT650℃×2h)

Sizes Available, Shielding Gas

| Size. | Shielding Gas |

|---|---|

| 1.2 | CO2 or Ar+20%CO2, 20L/min |

| 1.6 | CO2 or Ar+20%CO2, 20L/min |

GFW AP Series

Applications and Characteristics

AP series wire corresponds to JIS TSXXX-FC1, AWS EXXXT1-1 type wire and is suitable for positional welding with proper slag viscosity. Of course, AP Series wires are applicable in flat position and horizontal position. Shielding gas is limited to CO2 gas only.

| Trade Name | Position | Chemical Composition (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | ||

| GFW308LAP | Flat | 0.024 | 0.42 | 1. | 0.026 | 0.004 | 10. | 20. | 0.02 | 0.02 |

| Vertical Upward | 0.027 | 0.46 | 1. | 0.027 | 0.005 | 10. | 19. | 0.02 | 0.01 | |

| GFW3091-AP | Flat | 0.023 | 0.42 | 1. | 0.026 | 0.007 | 12. | 23. | 0.01 | 0.03 |

| Vertical Upward | 0.030 | 0.39 | 1. | 0.025 | 0.006 | 13. | 23. | 0.01 | 0.02 | |

| GFW316LAP | Flat | 0.023 | 0.42 | 1. | 0.028 | 0.004 | 13. | 19. | 2. | 0.03 |

| Vertical Upward | 0.032 | 0.44 | 1. | 0.026 | 0.005 | 13. | 19.10 | 2. | 0.03 | |

| GFW309MoLAP | Flat | 0.027 | 0.36 | 2. | 0.027 | 0.005 | 13. | 23. | 2. | 0.05 |

| Vertical Upward | 0.034 | 0.39 | 2. | 0.026 | 0.005 | 13. | 23. | 2. | 0.03 | |

| •Typical Mechanical Properties of All welded Metal | (Flat position) | |

|---|---|---|

| Tensile Strength Trade Name (MPa) | 5D Elongation (%) | |

| GFW308LAP | 560 | 40. |

| OFW309LAP | 584 | 36. |

| GFW316LAP | 564 | 37. |

| OFW309MoLAP | 593 | 34. |

•Recommended Welding Conditions

| Position | Welding Current (A) | Welding Voltage Welding Speed (V) (mm/min) |

|---|---|---|

| Flat | 170^200 | 28-42 200–400 |

| Horizontal | 170^200 | 28-42 200–400 |

| Vertical Upward | 130—- 170 | 24^26 80.–200 |

| Vertical Downward | 180^200 | 26^28 400–600 |

| Overhead | 140– 170 | 24^-26 250–450 |

Welding Conditions:

| Position | Welding Current (A) | Welding Voltage (V) | Welding Speed (mm/min) | Weaving Width (mm) |

|---|---|---|---|---|

| Specifications | 150 | 25 | 10 | 8 |

GFW309

Applications and Characteristics

TASETO GFW309 is designed with higher Ni, Cr, and ferrite content than those of Type 308 weld metal. So, GFW309 is used for welding dissimilar metals such as stainless steel to carbon steel or to low alloy steel, welding the first layer of stainless steel side in joining clad steel, and welding the first layer of overlay welding on carbon steel or low alloy steel.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | |

|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.034 | 0.63 | 1.41 | 0.018 | 0.003 | 12.62 | 24.28 | 0.02 | 0.03 |

● Ferrite Content of All Weld Metal

* Typical Ferrite Content: 13.4% (Schaeffler’s Diagram)

>18FN (DeLong’s Diagram)

20% (Ferrite Scope)

● Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | |

|---|---|---|---|

| Typical | 452 | 603 | 33.0 |

Sizes Available, Shielding Gas and Approvals

| Size (mm) | Shielding Gas |

|---|---|

| 1.2 | CO2 or Ar+20%CO2, 20L/min |

| 1.6 | CO2 or Ar+20%CO2, 20L/min |

GFW309L

Applicable Specification

JIS Z 3323 TS309L-FB0

AWS A5.22 E309LT0-1/4

Applications and Characteristics

TASETO GFW309L has the same composition as GFW309, except low carbon content of less than 0.04%. So this wire is suitable for welding the first layer of low carbon type stainless steel overlay or clad steel.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | |

|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.025 | 0.61 | 1.31 | 0.015 | 0.004 | 12.55 | 24.12 | 0.02 | 0.02 |

Ferrite Content of All Weld Metal

Typical Ferrite Content: 14.2% (Schaeffler’s Diagram)

>18FN (DeLong’s Diagram)

22% (Ferrite Scope)

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | |

|---|---|---|---|

| Typical | 431 | 595 | 35.0 |

Sizes Available, Shielding Gas

| Size (mm) | Shielding Gas |

|---|---|

| 1.2 | CO2 or Ar+20%CO2, 20L/min |

| 1.6 | CO2 or Ar+20%CO2, 20L/min |

GFW309Mo

Applicable Specification

JIS Z 3323 TS309Mo-FB0

AWS A5.22 E309LMoT0-1/4

Applications and Characteristics

TASETO GFW309Mo has the same uses as GFW309. As Mo is added about 2% in weld metal, GFW309Mo is suitable for welding the first layer of Type 316 stainless steel overlay or clad steel.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | |

|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.034 | 0.60 | 1.19 | 0.020 | 0.003 | 12.82 | 22.87 | 2.37 | 0.02 |

Ferrite Content of All Weld Metal

Typical Ferrite Content: 15.5% (Schaeffler’s Diagram)

>18FN (DeLong’s Diagram)

24% (Ferrite Scope)

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | |

|---|---|---|---|

| Typical | 500 | 683 | 32.0 |

Sizes Available, Shielding Gas

| Size (mm) | Shielding Gas |

|---|---|

| 1.2 | CO2 or Ar+20%CO2, 20L/min |

| 1.6 | CO2 or Ar+20%CO2, 20L/min |

GFW309MoL

Applicable Specification

JIS Z 3323 TS309LMo-FB0

AWS A5.22 E309LMoT0-1/4

Applications and Characteristics

TASETO GFW309MoL has the same uses as GFW309Mo. As the carbon content is decreased to 0.04% or less, it is suitable for welding the first layer of Type 316L stainless steel overlay or clad steel.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | |

|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.021 | 0.64 | 1.15 | 0.020 | 0.003 | 12.69 | 23.08 | 2.31 | 0.02 |

Ferrite Content of All Weld Metal

Typical Ferrite Content: 18.3% (Schaeffler’s Diagram)

>18FN (DeLong’s Diagram)

25% (Ferrite Scope)

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | |

|---|---|---|---|

| Typical | 515 | 686 | 30.0 |

● Sizes Available, Shielding Gas

| Size (mm) | Shielding Gas |

|---|---|

| 1.2 | CO2 or Ar+20%CO2, 20L/min |

| 1.6 | CO2 or Ar+20%CO2, 20L/min |

GFW310E

Applicable Specification

JIS Z3323 TS310-FC0

AWS A5.22 E310T0-1

Applications and Characteristics

TASETO GFW310E is used for welding AISI310 or SUS310S and welding dissimilar metals such as stainless steel and carbon steel combinations. Weld metal has excellent corrosion resistibility and heat resistance, because of the higher content of Cr and Ni than Type 308 weld metal.

Notes on Usage

Please refer to “Guideline for Welding Stainless Steel with GFW Wires”.

* Because of the fully austenitic structure of weld metal, the weld metal susceptibility to hot cracking is high. So, the welding current must be kept within 150~200A. In the case of highly restrained conditions, it must be kept within 150~170A. Keep the interpass temperature at 120℃ or below. To minimize crater cracks, fill craters with filler metal and remove crater cracks with a grinder.

Use 100%CO2 as shielding gas.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | |

|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.170 | 0.45 | 2.03 | 0.022 | 0.003 | 20.63 | 25.40 | 0.04 | 0.03 |

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | |

|---|---|---|---|

| Typical | 391 | 592 | 37.0 |

Sizes Available and Shielding Gas

| Size (mm) | Shielding Gas |

|---|---|

| 1.2 | 100% CO2, 20L/min |

GFW312

Applications and Characteristics

TASETO GFW312 contains a higher amount of ferrite than Type 309 all weld metal. It is suited for dissimilar metal joints and overlay welding of carbon steel containing a higher amount of carbon or nickel. Because of high ferrite content, post-weld heat treatment can result in embrittlement.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | |

|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.110 | 0.48 | 1.39 | 0.025 | 0.002 | 8.99 | 28.60 | 0.01 | 0.02 |

Ferrite Content of All Weld Metal

* Typical Ferrite Content: >20% (Schaeffler’s Diagram)

>18FN (DeLong’s Diagram)

36% (Ferrite Scope)

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | |

|---|---|---|---|

| Typical | 565 | 714 | 23.0 |

Sizes Available and Shielding Gas

| Size (mm) | Shielding Gas |

|---|---|

| 1.2 | CO2 or Ar+20%CO2, 20L/min |

GFW316

Applicable Specification

JIS Z 3323 TS316-FB0

AWS A5.22 E316T0-1/4

Applications and Characteristics

TASETO GFW316 is used for welding Type 316 stainless steel. This wire has good corrosion resistibility against non-oxidizing acids (e.g. acetic acid, dilute sulfuric acid) and salts.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | |

|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.036 | 0.54 | 1.24 | 0.020 | 0.007 | 11.80 | 18.87 | 2.25 | 0.05 |

Ferrite Content of All Weld Metal

* Typical Ferrite Content: 7.3% (Schaeffler’s Diagram)

12.1FN (DeLong’s Diagram)

13% (Ferrite Scope)

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | Absorbed Energy (J at 0℃) | |

|---|---|---|---|---|

| Typical | 392 | 556 | 43.0 | 55 |

Corrosion Resistance of All Weld Metal

*Typical Corrosion Resistance 7.78 g/m2・h ( 5% Sulfuric Acid Test )

Sizes Available, Shielding Gas

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | Absorbed Energy (J at 0℃) | |

|---|---|---|---|---|

| Typical | 392 | 556 | 43.0 | 55 |

GFW317L

Applicable Specification

JIS Z 3323 TS317L-FB0

AWS A5.22 E317LT0-1/4

Applications and Characteristics

TASETO GFW317L contains more Mo than GFW316L and has excellent resistance to pitting and intergranular corrosion. GFW317L is used for welding of Type 317 and Type 317L stainless steel used in bleaching equipment.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | |

|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.021 | 0.60 | 1.32 | 0.021 | 0.005 | 13.20 | 19.04 | 3.48 | 0.03 |

Ferrite Content of All Weld Metal

* Typical Ferrite Content: 8.2% (Schaeffler’s Diagram)

13.5FN (DeLong’s Diagram)

16% (Ferrite Scope)

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | Absorbed Energy (J at 0℃) | |

|---|---|---|---|---|

| Typical | 423 | 589 | 35.0 | 59 |

Corrosion Resistance of All Weld Metal

* Typical Corrosion Resistance 5.12g/㎡・h (5% Sulfuric Acid Test)

180°bend without any defects

(Copper Sulfate-Sulfuric Acid Test: PWHT 650℃×2h)

Sizes Available, Shielding Gas

| Size (mm) | Shielding Gas |

|---|---|

| 1.2 | CO2 or Ar+20%CO2, 20L/min |

| 1.6 | CO2 or Ar+20%CO2, 20L/min |

GFW347

Applicable Specification

JIS Z 3323 TS347-FB0

AWS A5.22 E347T0-1/4

Applications and Characteristics

TASETO GFW347 has excellent resistibility to intergranular corrosion, because of the carbon stabilizing effect of Nb added in the weld metal. It is used for welding Type 347 and Type 321 stabilized stainless steel.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Nb+Ta | |

|---|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.043 | 0.31 | 1.19 | 0.022 | 0.012 | 9.93 | 19.02 | 0.04 | 0.03 | 0.55 |

Ferrite Content of All Weld Metal

* Typical Ferrite Content: 6.3% (Schaeffler’s Diagram)

7.9FN (DeLong’s Diagram)

10% (Ferrite Scope)

Mechanical Properties of All Weld Metal

| Test Temp. (℃) | 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) |

|---|---|---|---|

| Room Temp. | 425 | 611 | 38.0 |

| 500 | 295 | 424 | 23.0 |

| 600 | 278 | 365 | 19.2 |

| 700 | 266 | 300 | 14.0 |

Corrosion Resistance of All Weld Metal

* Typical Corrosion Resistance : 0.00074 in/month(0.21 g/㎡・h) (65% Nitric Acid Test )

: 180°bend without any defects (Copper Sulfate-Sulfuric Acid Test: PWHT 650℃×2h)

Sizes Available, Shielding Gas

| Size (mm) | Shielding Gas |

|---|---|

| 1.2 | CO2 or Ar+20%CO2, 20L/min |

| 1.6 | CO2 or Ar+20%CO2, 20L/min |

GFW347L

Applicable Specification

JIS Z 3323 TS347L-FB0

AWS A5.22 E347T0-1/4

Applications and Characteristics

TASETO GFW347L has the same uses as GFW347. As it contains less carbon than GFW347, the resistance to intergranular corrosion is better than GFW347. GFW347L is suitable for overlay welding of Type 321 or 347 stainless steel.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Nb+Ta | |

|---|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.020 | 0.36 | 1.11 | 0.022 | 0.015 | 10.40 | 18.25 | 0.02 | 0.02 | 0.61 |

Ferrite Content of All Weld Metal

* Typical Ferrite Content: 5.1% (Schaeffler’s Diagram)

5.1FN (DeLong’s Diagram)

9% (Ferrite Scope)

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | Absorbed Energy (J at 0℃) | |

|---|---|---|---|---|

| Typical | 424 | 592 | 40.0 | 50 |

Corrosion Resistance of All Weld Metal

* Typical Corrosion Resistance : 0.00074 in/month(0.21 g/㎡・h) (65% Nitric Acid Test)

: 180°bend without any defects (Copper Sulfate-Sulfuric Acid Test: PWHT 650℃×2h)

Sizes Available, Shielding Gas

| Size (mm) | Shielding Gas |

|---|---|

| 1.2 | CO2 or Ar+20%CO2, 20L/min |

| 1.6 | CO2 or Ar+20%CO2, 20L/min |

GFW329J3L

Applicable Specification

JIS Z 3323 TS2209-FC0

AWS A5.22 E2209T0-1

Applications and Characteristics

TASETO GFW329J3L is used for welding duplex stainless steel such as Type 2205, UNS S31803, and lean duplex stainless steel such as UNS S32101, and S32304. Weld metal has excellent resistance to pitting corrosion and stress corrosion cracking. It has also resistance to seawater and phosphate.

Notes on Usage

* Please refer to “Guideline for Welding Stainless Steel with GFW Wires”.

Post-weld heat treatment causes severe embrittlement of weld metal.

Use 100%CO2 as shielding gas.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.029 | 0.47 | 0.88 | 0.018 | 0.005 | 9.10 | 23.38 | 3.25 | 0.03 | 0.13 |

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 5D Elongation (%) | |

|---|---|---|---|

| Typical | 577 | 790 | 30.0 |

Corrosion Resistance of All Weld Metal

* Typical Corrosion Resistance: 2.82 g/m2・h (5% Sulfuric Acid Test)

:8.92 g/m2・h (Ferric Chloride Test)

Sizes Available and Shielding Gas

| Size (mm) | Shielding Gas |

|---|---|

| 1.2 | CO2, 20L/min |

| 1.6 | CO2, 20L/min |

GFW2594

Applicable Specification

JIS Z 3323 TS329J4L-FC0

AWS A5.22 E2594T0-1

Applications and Characteristics

TASETO GFW2594 is used for welding of super duplex stainless steel such as UNS S32750, and S32760. As weld metal has a higher pitting resistance equivalent (PRE※) value than that of GFW329J4L, GFW2594 is suitable for more corrosive environment.

※ PRE = Cr% + 3.3xMo% + 16xN%

Notes on Usage

Preheating is not necessary and interpass temperature should be kept under 150℃.

Post-weld heat treatment causes severe embrittlement of weld metal.

Use 100%CO2 as shielding gas.

Chemical Composition of All Weld Metal (%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | W | N | PRE | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.030 | 0.51 | 0.86 | 0.015 | 0.004 | 9.56 | 26.12 | 3.51 | 0.87 | 0.75 | 0.23 | 41.4 |

Ferrite Content of All Weld Metal

WRC-1992 Diagram

Typical 65 FN

Tensile Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 4D Elongation (%) | |

|---|---|---|---|

| Typical | 687 | 891 | 28.0 |

Corrosion Resistance of All Weld Metal

Typical CPT in 6% Ferric Chloride Test (JIS G 0578) 35℃

Sizes Available and Shielding Gas

| Size (mm) | Shielding Gas |

|---|---|

| 1.2 | CO2, 20L/min |

GFW82

Applicable Specification

AWS A5.34 TNi6082-04

Applications and Characteristics

TASETO GFW82 can be applied to the welding of a wide variety of materials, such as welding of nickel alloy 600 (UNS N06600) or nickel alloy 601 (UNS N06601), welding of nickel alloy 800 (UNS N08800), welding of the dissimilar metal joint such as nickel alloy to nickel, stainless steel, or to low alloy steel, and welding of stainless steel to low alloy steel in high-temperature service. Also, it can be applied to the welding of clad steel and overlay welding on carbon steel.

Notes on Usage

* To minimize crater crack, fill craters with filler metal and remove crater crack with a grinder

Chemical Composition of All Weld Metal(%)

| C | Mn | Fe | P | S | Si | Cu | Ni | Ti | Cr | Nb+Ta | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.027 | 3.08 | 2.32 | 0.009 | 0.001 | 0.29 | Tr. | 69.80 | 0.49 | 21.57 | 2.71 |

Mechanical Properties of All Weld Metal

Sizes Available and Recommended Welding Conditions

| Size (mm) | Flat | Horizontal | ||||

|---|---|---|---|---|---|---|

| Current (A) | Voltage (V) | Speed (mm/min) | Current (A) | Voltage (V) | Speed (mm/min) | |

| 1.2 | 160-190 | 26-31 | 250-350 | 130-160 | 25-28 | 300-400 |

GFW625

Applicable Specification

AWS A5.34 TNi6625-04

Applications and Characteristics

TASETO GFW625 can be applied to welding of nickel alloy 625 (UNS N06625), welding of nickel alloy 800 (UNS N08800), welding on the clad side of nickel alloy 625 (UNS N06625) or nickel alloy 825 (UNS N08825) clad steel, and overlay welding of carbon steel. As GFW625 has a high PRE value and good resistivity for pitting corrosion, it can apply to welding of UNS S31254 class austenitic super stainless steel.

Notes on Usage

* To minimize crater crack, fill craters with filler metal and remove crater crack with a grinder.

Chemical Composition of All Weld Metal(%)

| C | Mn | Fe | P | S | Si | Cu | Ni | Ti | Cr | Cb+Ta | Mo | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.031 | 0.05 | 3.43 | 0.001 | 0.001 | 0.26 | 0.12 | 60.17 | 0.24 | 22.78 | 3.25 | 9.71 |

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 4D Elongation (%) | |

|---|---|---|---|

| Typical | 481 | 744 | 45 |

Sizes Available and Recommended Welding Conditions(DCEP)

| Size (mm) | FLat | Horizontal | ||||

|---|---|---|---|---|---|---|

| Current (A) | Voltage (V) | Speed (mm/min) | Current (A) | Voltage (V) | Speed (mm/min) | |

| 1.2 | 160-190 | 26-31 | 250-350 | 130-160 | 25-28 | 300-400 |

GFWHsC276

Applicable Specification

AWS A5.34 TNi6276-04

Applications and Characteristics

TASETO GFWHsC276 is used for welding of nickel alloy C (UNS N10002), nickel alloy C-276 (UNS N10276) to steel, and nickel alloy clad steel. It is also applicable for overlay welding.

As GFWHsC276 has a high PRE value and good resistivity for pitting corrosion, it can apply to welding of UNS S31254 class austenitic super stainless steel.

Notes on Usage

* To minimize crater crack, fill craters with filler metal and remove crater crack with a grinder.

Chemical Composition of All Weld Metal(%)

| C | Mn | Fe | P | S | Si | Cu | Ni | Co | Cr | Mo | V | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.014 | 0.32 | 6.18 | 0.011 | 0.002 | 0.12 | 0.04 | Rem | 1.18 | 15.84 | 16.12 | 0.03 | 3.65 |

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 4D Elongation (%) | Absorbed Energy (2mmVE0, J) | |

|---|---|---|---|---|

| Typical | 520 | 727 | 31 | 71 |

Corrosion Resistance of All Weld Metal

(Corrosion loss: g/㎡・h)

| 30% Hydrochloric Acid (40℃×1h) | 30% Sulfuric Acid (40℃×1h) | |

|---|---|---|

| Typical | 0.21 g/㎡・h | 0.21 g/㎡・h |

Sizes Available and Recommended Welding Conditions

| Size (mm) | Flat | Horizontal | ||||

|---|---|---|---|---|---|---|

| Current (A) | Voltage (V) | Speed (mm/min) | Current (A) | Voltage (V) | Speed (mm/min) | |

| 1.2 | 160-190 | 26-31 | 250-350 | 130-160 | 25-28 | 300-400 |

GFWHsC-22

Applications and Characteristics

TASETO GFWHsC-22 is used for the welding of nickel alloy C-22 (UNS N06022) or overlay welding. Also used for welding petrochemicals and various chemical equipment that is required for the resistibility against oxidizing and reducing acid.

Notes on Usage

* Only Ar+20%CO2 is permitted for use as shielding gas.

* To minimize crater crack, fill craters with filler metal and remove crater crack with a grinder.

Chemical Composition of All Weld Metal(%)

| C | Mn | Fe | P | S | Si | Cu | Ni | Co | Cr | Mo | V | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Typical | 0.018 | 0.34 | 5.46 | 0.008 | 0.002 | 0.18 | 0.04 | Rem | 0.81 | 21.44 | 12.95 | 0.23 | 3.11 |

Mechanical Properties of All Weld Metal

| 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | 4D Elongation (%) | |

|---|---|---|---|

| Typical | 515 | 717 | 30 |

Corrosion Resistance of All Weld

(Corrosion loss: g/㎡・h)

| 1.5% Hydrochloric Acid (boiling) | 30% Sulfuric Acid (boiling) | 30% Nitric Acid (boiling) | |

|---|---|---|---|

| Typical | 0.42 g/㎡・h | 0.091 g/㎡・h | 0.032 g/㎡・h |

Sizes Available and Recommended Welding Conditions

| Size (mm) | Flat | Horizontal | ||||

|---|---|---|---|---|---|---|

| Current (A) | Voltage (V) | Speed (mm/min) | Current (A) | Voltage (V) | Speed (mm/min) | |

| 1.2 | 160-190 | 26-32 | 250-350 | 130-160 | 25-28 | 300-400 |