Taseto

TASETO JIKI CHECK Magnetic Particle Inspection

Product Made in Japan

Manufacturer: TASETO

Model: JIKI CHECK

Applications

Ferromagnetic metals (mild steels, high

tensile steels, steel castings)

● Features

1. Excellent in detecting surface flaws on ferromagnetic steels (unusable for non-magnetic materials).

2. Can also detect flaws that are not open to the surface.

3. Low testing cost

4. LED Blacklight is cordless

● Principle

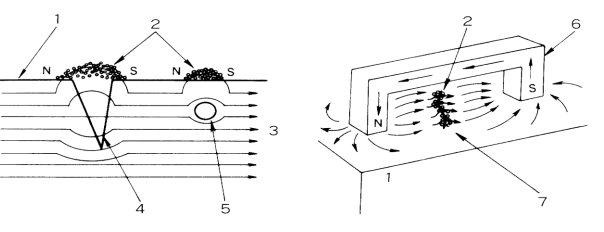

Applying a high current to a magnetized object, or exciting an object placed in a strong magnetic field causes the magnetic field to bend by discontinuities such as cracks or pinholes, which exist on the object surface or relatively shallow subsurface, to leak out at the defective surface as if magnetic poles were produced there. If you apply TASETO JIKI CHECK to the leakage surface, its magnetic particles are absorbed over a wide range by the defective surface, thus making minute flaws visible to the naked eye. The magnetic particle testing method employs the principle.

Key:1. Item to be inspected 2. Magnetic particles 3. Magnetic field 4. Surface flaw 5. Internal flaw 6. Magnetic pole 7. Flaw

Testing Method

The magnetic particle testing follows the procedure as follows.

Pre-cleaning

Magnetization (direct current, current induction, prod, coil or yoke method)

Application of TASETO JIKI CHECK

(continuous, residual, spraying, immersion, wet or dry method)

Interpretation (under white light or black light in a dark room)

Demagnetization (attenuation or transmission method)

Product List

Fluorescent magnetic Particles

| Designation | Fluorescent color | Mean particle size | Application | Characteristics |

|---|---|---|---|---|

| F-300 | Greenish yellow | 7.0μm | Raw materials | General inspection |

| F-330(E) | Greenish yellow | 5.0μm | Precision parts | Precision inspection. Standard type |

| F-660 | Greenish yellow | 4.5μm | Precision parts | Precision inspection |

| F-910 | Greenish yellow | 10μm | Automated testing | Very high brightness, good durability. |

| G-660 | Greenish yellow | 4.5μm | Precision parts | Instant type, no dispersing agent is required. |

Non-fluorescent magnetic particles

| Designation | Appearance | Mean particle size | Method |

|---|---|---|---|

| B-100 | Black powder | 15μm | Dry |

| B-200 | Black powder | 5μm | Wet |

| B-200 | Aerosol | 1μm | Wet |

Contrast Paint

| Contrast Paint | M1 | Aerosol |

|---|

Dispersible agents for magnetic particles

| Designation | Addition rate | Characteristics |

|---|---|---|

| SP-700 | 1~2% | Good dispersibility and wettability of magnetic particles. Also excellent in defoaming and rust resistance. |

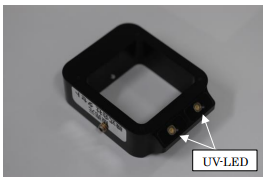

Induced type LED blacklight (cordless)