Bending, Japan, Toyo Kensetsu Kohki

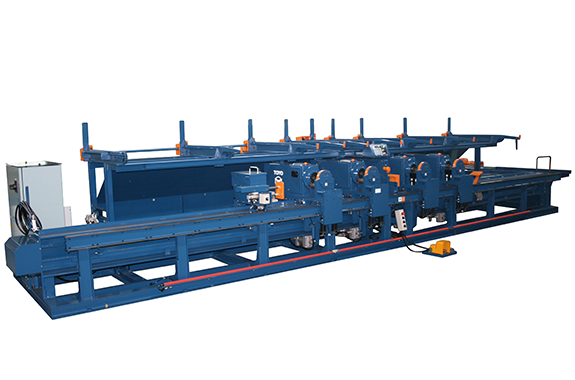

TOYO KENSETSU KOHKI TBS-25-NC4RV AUTO REBAR BENDING

Products Made in Japan

Manufacturer: TOYO KENSETSU KOHKI

Model: TBS-25-NC4RV

Features

- AUTO REBAR BENDING

- Bar (Small)

- Bar (Large)

- Reduce manpower

- Mass production

- High strength rebar processing

- Rebar fabrication

- Precast concrete

| Model | TBS-25-NC4RV |

|---|---|

| Capacity | SD390: D10-9 ~ D25-1 SD490: D10-9 ~ D25-1 SD785: D10-8 ~ D16-3 |

| Required breaker capacity | 50A |

| Bending unit revolution | 2.5~7.5rpm |

Machine & Processing

Specifications

| Specifications | TBS-25-NC4RV (10m) |

| Required breaker capacity | 50A |

| Min, distance between fulcrum centers | 390mm(No.2-3) |

| Max, distance between fulcrum centers | 9,340mm(No.1-4) |

| Bending angle | 15~180° |

| Bending unit revolution | 2.5~7.5 rpm(50/60Hz) |

| Total motor capacity | 12.55kW (including air-compressor) |

| Dimensions (LXWXH) | 10,435×2,260×1,605mm |

| Total weight | 6,400kg |

Similtaneous Max. Bending Quantity (pcs).

| Rebar diameter | D10 | D13 | D16 | D19 | D22 | D25 |

| Fulcrum roller dia. | Φ39 | Φ52 | Φ62 | Φ74 | Φ86 | Φ97 |

| SD390 | 9 | 7 | 5 | 3 | 2 | 1 |

| SD490 | 9 | 7 | 4 | 2 | 1 | 1 |

| SD785 | 8 | 5 | 3 | _ | _ | _ |

Details

・TBS-25-NC4RV is an automatic rebar bending machine which is for bending high-strength rebar (SD785 D10-D16, SD490 D10-D25).

・TBS-25-NC4RV is most suitable for bending closed stirrups, railway construction and building construction.

・Chucking device grabs rebar, which raises the dimension accuracy of finished products.

・Shapes, dimensions and angles can be easily set on the user-friendly touch screen.

・Touch screen is placed in the middle, which raises working efficiency.

・Taking material grade into consideration, inverter is equipped in order to raise the bending accuracy.

・Number counter device is built-in, which is capable of counting q’ty of rebar mechanically.

・With the numeric control, it is not necessary to measure dimensions manually.

・Bending speed change function is available.”

Other items of TOYO KENSETSU KOHKI

Request the quotation for TOYO KENSETSU KOHKI

Related Products

-

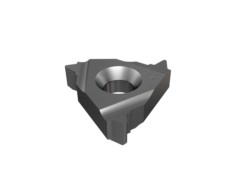

SAKUSAKU 16IR AG60 External Threading Insert General-Purpose 60°

-

Shimizu Kusunuki Taro Handy for Gardening

-

Tosei Sharyo GLH Series (Folding Handle) Gold Lifter

-

Kyowa PVL-10KA PVL Voltage-output Pressure Transducer

-

Kyowa BEE-A-1MP BEE-A Soil Pressure Transducer

-

NAGANO KEIKI JC__ Pressure Gauge with Electric Contact