Japan, UHT CORPORATION

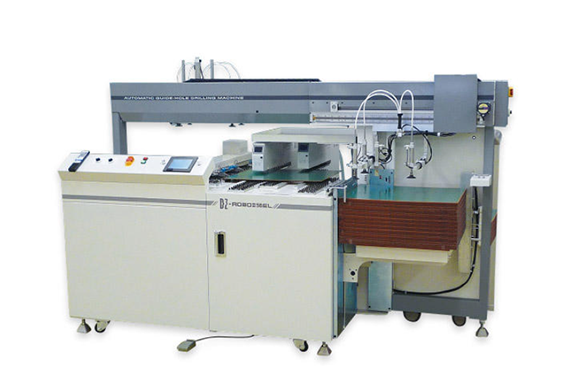

UHT Corporation DZ-ROBOⅡ56EL Series Automatic Guide-Hole Drilling Machine

Made in Japan

Manufacturer: UHT CORPORATION

Model: DZ-ROBOⅡ56EL Series

It is possible to carry the image processing type of two drilling cells.

High accuracy, high productivity machine.

Easy programming by teaching method

The electric spindle correspondence and it is the conservation of energy and low noise.

Characteristics

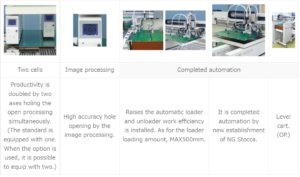

Processing with two drill cells simultaneously.

Productivity improves greatly by two axes in the corner processing simultaneously. (The standard is equipped with one. When the option is used, it is possible to equip with two.)

Highly accurate processing by picture processing.

Various mark patterns are corresponding to high accuracy and adapt by image processing and grey search (OP.) by binarization. The processing program operates by the original teaching method easily.

Standard Specifications

| Model name | DZ-ROBOⅡ56EL | |

| usage | Guide hole opening | |

| Work | Material | One-side and two-sided printed substrate |

| Size | Max.W610×D510mm Min.W300×D250mm | |

| Thickness | Standard t1.6 mm | |

| Drilling area | Max.W610×D510mm Min.W300×D250mm Except for the 20×W60mm range from the end side of the finger clamp part | |

| Fixed method | Finger clamping method | |

| Processing speed | 13sec/4 hole processing (cycle time including loading)(Two DZ cells processing simultaneously and axis movement pitch 250mm time) | |

| DZ(drill)cell | Equipped with one DZ-8E(It is possible to equip with two by option.) | |

| Capability | Drilling accuracy | XY axis ±25μm |

| Drilling speed | 1.2 sec/holes (Image processing~drilling that depends on the standard worksheet of our company) | |

| Holing open ability | φ1.0~φ3.2 mm (1/8″collet) | |

| The rotational speed of the main axis | Max. 50000rpm | |

| Image processing | Display | 2.5インチLCD |

| Mark size | φ0.6~φ3.0mm | |

| Method | Centre of gravity search by binarization(Pattern matching by grey processing(OP.)) | |

| Range of view | Standard view.5×4mm Digitized view.4.5×3.5mm | |

| Illumination | LED | |

| Loader and unloader | Height of work loading | Max. 500mm |

| Loading From | Level cart (op) | |

| Error processing | When image processing makes an error, work carrying out to NG stock. | |

| Operation | The main body is operated by the liquid crystal touch panel and the DZ cell is operated by the remote control | |

| Data | Punch data | Teaching input |

| Preservation | Controller internal and capacitor backup(For one week.) And, it preserves it on the personal computer by data transfer. | |

| Memory capacity | They are ten channels in 1000 positions/channels. | |

| Safety device | Safety cover(OP.) | |

| Power Supply | main body:3φ AC200V ±10% 1kVA DZ cell:1φ AC85~240V 200VA | |

| Air Supply | 0.5MPa(clean air) | |

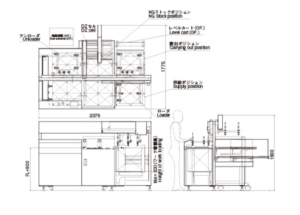

| Machine size | W2375mm×D1775mm×H1600mm | |

| Machine mass | Approx.500kg | |

| Working condition | Temperature | 10~35℃(22±2℃ recommended) |

| Humidity | 40~60%(Non-dewing) | |

| Accessory | ・One infrared rays remote controller ・Electric micro spindle complete set ・Pin spanner complete set. | |

Options

One DZ cell (DZ-8E) is a standard.

Level cart (MAX.200kg)

Dust extractor (AC200V 1.9kw)

Loader work pusher

Safety cover

Personal computer for data storage・Software

Gray search.

Outline Drawing