Japan, UHT CORPORATION

UHT CORPORATION FP-1210L series Linear type flexible substrate punching machine

Made in Japan

Manufacturer: UHT CORPORATION

Model: FP-1210L

Features

- Various processing by the model punch unit

- Speed-up FP

Super-high-speed X and Y axis are installed. - Max. 1500 hole/min (with PUM-25L) 2.5 times faster than conventional models.

Low vibration / Quiet machine

Characteristics

- Corresponding to all the processes by the strange appearance punch and the metal mold

- Minute hole, Standard hole, Cavity, Trim, Punch, and Chisel-blanking die, cut, etc.

- It supports various subject matter

- Corresponding to PCB・ Metallic substrate Flexible substrate (FPC)・large size ceramic green sheet ,etc.

- High speed and a highly accurate processing by the linear motor drive are achieved.

- Speed-up is achieved by work movement of X and Y axis linear motor drive and making of punching unit linear actuator, etc.

- Corresponding to the size of the work with 510×260mm

Standard Specifications

| Model name | FP-1210L | |

|---|---|---|

| Work | Material | Flexible substrate (FPC)・large size ceramic green sheet,etc. Corresponding to PCB・Metallic substrate |

| Thickness | Max.0.5mm | |

| Size | Max.510×260mm | |

| Machining area | Max.500×250mm | |

| Way of installing | Supply : Sheet : Standard work holder, Vacuum frame Roll : Vacuum frame |

|

| Punch units(OP.) | Number of installing(in the PU-25 size) | 12axes |

| Capability | Punching precision | ±10μm(precision at the machining point within 25mm pitch in the standard punching range using UHT test film) |

| Punching speed | Max.1500 holes/min (PUM-25L is used.) Max.1000 holes/min (PU-25L is used.) Max.600 holes/min (PU-25A is used.) (NC punch with 1mm pitch in Y direction on standard V/H work holder) |

|

| System | Drive method | XYaxis linear motor |

| Control function | Control unit | UHT made controller exclusively for mechanism control |

| Operation | Operation with 6.5-inch color liquid crystal graphical touch panel | |

| Machining data preparation | Software on PC (independent of the main body) | |

| Number of processing data memories | 1 file (MAX.30,000 positions) | |

| Network | Transmission of machining data from PC to the machine through LAN. The operation situation up to Max.4 main body can be monitored intensively by the PC. |

|

| Image processing method | Image data processing is executed by the image processing function with CCD only made of UHT. | |

| Static eliminating unit | Air/ionizers installed in the upper and lower parts of the left side of the punching unit | |

| Power source | 3φ AC200V ±10% 2kVA | |

| Air pressure source | 0.4~0.7MPa | |

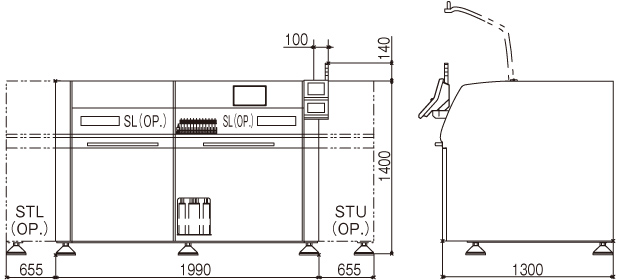

| Machine size | W1990×D1300×H1400mm | |

| Machine weight (Body) | Approx. 1750kg | |

| Working condition | Temperature | 10~35℃(22±2℃ recommended) |

| Humidity | 40~60%(Non-dewing) | |

Options

- Punch units

- Metal mold(Punch, Die)

- Metal mold unit

- Punch setter

- Broken punch detector soft

- work holder

- Automation device

- Management PC

- Data conversion software from CAD

- Power box

- Booster tank

- Lift car

- Front safety sensor

Outline Drawing

Related Products

-

Tohnichi FDD-AD Direct Reading Torque Wrench

-

Watanabe WVP-DBA Distributor (smart transmitter compatible, non-isolated) – Signal Converter

-

Chiyoda Seiki Glitter No. 00 Welder For Welding And Heating Work From Thin To Thick Plates (For AC)

-

TONE HA404LN Wheel Nut Socket Set For Impact Wrench (Thin, Long Type, With Socket Holder)

-

Kyowa EGPC-40A GPS/Multi-Channel CAN Card Option card for EDX-200A-2H/4H/4T

-

JPF BOLT SCREW Multi Type Screw Fixed Anchor