Japan, UHT CORPORATION

UHT Corporation PZ-Di/PZ-Dh Series Pilot Hole Punching Machine

Made in Japan

Manufacturer: UHT CORPORATION

Model: PZ-Di/PZ-Dh Series

Automatic positioning by image processing for various types of materials.

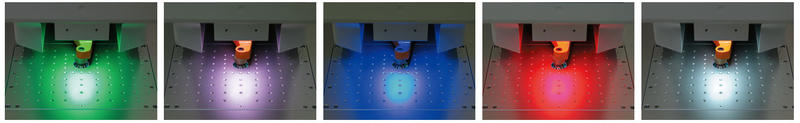

Grayscale or binary image processing and multi-color LED lights to support a wide variety of materials.

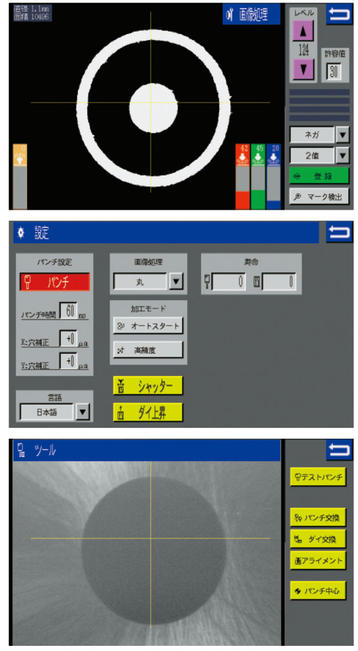

Setup and configuration via touch panel screen.

The graphic display is on a colour LCD touch panel screen for intuitive operation.

Environmentally friendly compact design.

Simple and compact design for enhanced workability and efficiency.

The standing job type is optionally available.

Uses

Through-hole drilling for phenol resin, glass epoxy resin, etc.

CHARACTERISTICS

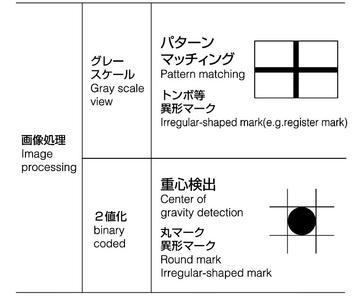

Image processing

Suitable image processing for marks can be selected.

LCD touch panel

The colour LCD touch panel screen has a monitor area to display target marks and an operation button area for intuitive use.

Menu Screen

Standard Specifications

| Model | PZ-Di | PZ-Dh | ||

|---|---|---|---|---|

| Work | Material | Glass epoxy/Flexible multilayer substrates/Nameplate | Metallic substrates/Nameplate/Flexible substrates | |

| Size | Max.610×510mm | |||

| Thickness | Max.1mm | Max.1.6mm | ||

| Die size | Punched hole diameter | φ0.6~6.0mm(OP.φ6.49mm) | φ0.6~6.0mm(OP.φ6.49mm) | |

| Capability | Punching power | 2500N | 8600N | |

| Punching accuracy | ±20μm | |||

| Punching speed | Max.1.0sec | Max.2.2sec | ||

| From pressing the foot pedal to completion of punching Under UHT’s processing conditions |

||||

| Image processing | Image processing | Centring by binary-coded | ||

| Pattern matching | ||||

| Display | Colour LCD touch panel | |||

| Mark size | φ0.6~3.0mm | φ0.6~6.0mm | ||

| Range of view | 5.3×4.0mm | 12×9mm | ||

| Light | Mulch-color LED lamp from the upper side (3 colours), LED lamp from the Lower side (White) | Mulch-colour LED lamp from the upper side (3 colors) | ||

| Control function | Operation | Operated by Color LCD touch panel | ||

| Table | Movable for correcting a vacuum position | |||

| Power source | Single phase AC100~240V 400VA | Single phase AC100~240V 500VA | ||

| Air source | 0.5MPa (Clean air) | |||

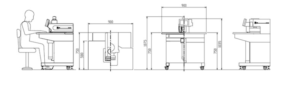

| Machine size | W900×D750×H1075mm | W900×D750×H1035mm | ||

| Machine weight | Approx.130kg | Approx.170kg | ||

| Option | Legs for standing work | |||

Options

Outline Drawing