Drilling And Cutting, Japan, Unika

UNIKA HC Hammer Core Drill

Manufacturer: UNIKA

Model: HC type (Set)/ HC type (Body)/ HC type (Shank Assembly)/ HC type (Center Pin)/ HC type (Guide Plate)

■Smoothly transmit powerful hammering and rotation force to offer rapid drilling through reinforced concrete(up to 10mm-reinforced).

■Extremely thin body incorporates double spiral to eliminate dispersion of drilling force due to swarf.

■Cope with thick concrete by using shank sizes up to 450mm long.

◆Effective Length: 100mm

◆Matching Drill: Hammer drill

USES

Concrete•Block•Brick

■Handling Procedure

-

Screw the shank into the core drill body.

*When removing the core body and the shank, place the body facing upward while inserted into the main unit and strike a few times to loosen the round screw. -

Insert and set the center pin while aligning it with hole on the tip end of the shank. Attach a guide plate to the set center pin.

-

Attach to the hammer drill as in the case with the conventional hexagonal shank drill and bull point.

-

Only the center pin is required for positioning. Pull out the center pin once the work material is drilled to a depth of approximately 5 mm and the drill tip end stops turning, then continue drilling operation.

■Drilling Data

- •Test conditions

-

- Core diameter used: 55 mm

- Subject material: Concrete (FC = 24.5 MPa)

- Drilling depth: 100 mm

- •Test Results

-

- Time required for drilling: 5 min.

- Drilling durability count: 100 pcs. or more

- Use electrical drills appropriate for the core drill used.

- Be sure to turn off the main switch of the drill and disconnect the power supply plug from the socket before attaching and detaching the core drills.

- Do not touch the core drill, the shavings, or the drilled hole because they may be hot.

- Wear working clothes suitable for the operation, including eye protection equipment to prevent shavings from getting into your eyes.

- Prepare the working environment before starting jobs.

- Read carefully the instruction manual for the electrical drill used before use.

■Compatible motors

| Manufacturer Name | Model No. | |

|---|---|---|

| Hammer Drill | HITACHI | PR25B |

| DH35 | ||

| PR38E | ||

| PR40SA | ||

| DH40SR | ||

| DH45SA | ||

| DH42 | ||

| Makita | HR3520 | |

| HR3530 | ||

| HR3850 | ||

| HR3811 | ||

| HR4030C | ||

| RYOBI | ED-383N | |

| ED-382NA | ||

| ED-382NP |

SPECIFICATION

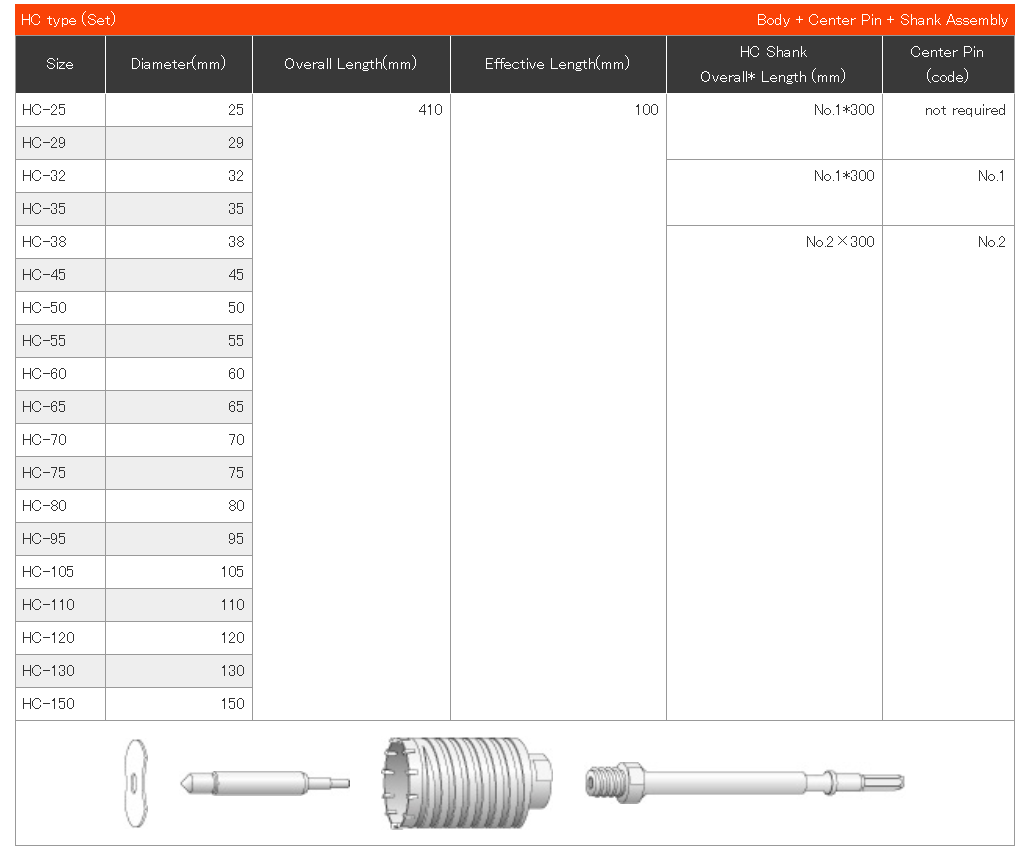

HC type (Set)

| Size | Diameter(mm) | Size | Diameter(mm) | Size | Diameter(mm) |

| HC-25 | 25 | HC-55 | 55 | HC-105 | 105 |

| HC-29 | 29 | HC-60 | 60 | HC-110 | 110 |

| HC-32 | 32 | HC-65 | 65 | HC-120 | 120 |

| HC-35 | 35 | HC-70 | 70 | HC-130 | 130 |

| HC-38 | 38 | HC-75 | 75 | HC-150 | 150 |

| HC-45 | 45 | HC-80 | 80 | ||

| HC-50 | 50 | HC-95 | 95 |

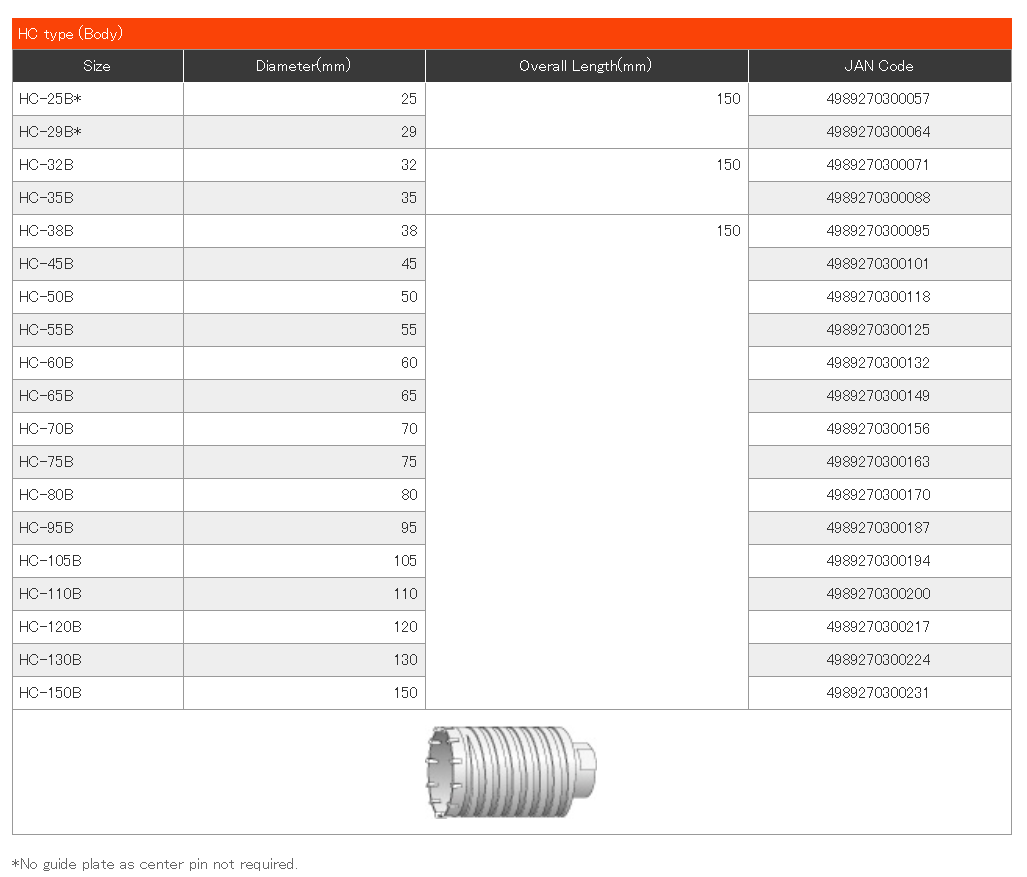

HC Type (Body)

| Size | Diameter(mm) | Size | Diameter(mm) | Size | Diameter(mm) |

| HC-25B* | 25 | HC-55B | 55 | HC-105B | 105 |

| HC-29B* | 29 | HC-60B | 60 | HC-110B | 110 |

| HC-32B | 32 | HC-65B | 65 | HC-120B | 120 |

| HC-35B | 35 | HC-70B | 70 | HC-130B | 130 |

| HC-38B | 38 | HC-75B | 75 | HC-150B | 150 |

| HC-45B | 45 | HC-80B | 80 | ||

| HC-50B | 50 | HC-95B | 95 |

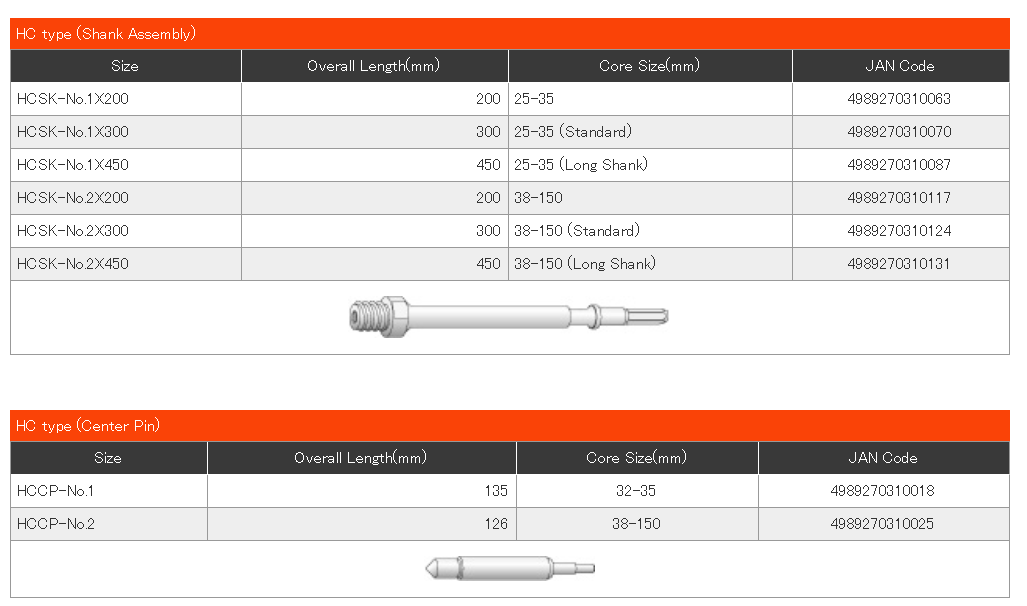

HC type (Shank Assembly) HC type (Center Pin)

| Size | Overall Length(mm) | Size | Overall Length(mm) | |

| HCSK-No.1X200 | 200 | HCCP-No.1 | 135 | |

| HCSK-No.1X300 | 300 | HCCP-No.2 | 126 | |

| HCSK-No.1X450 | 450 | |||

| HCSK-No.2X200 | 200 | |||

| HCSK-No.2X300 | 300 | |||

| HCSK-No.2X450 | 450 |

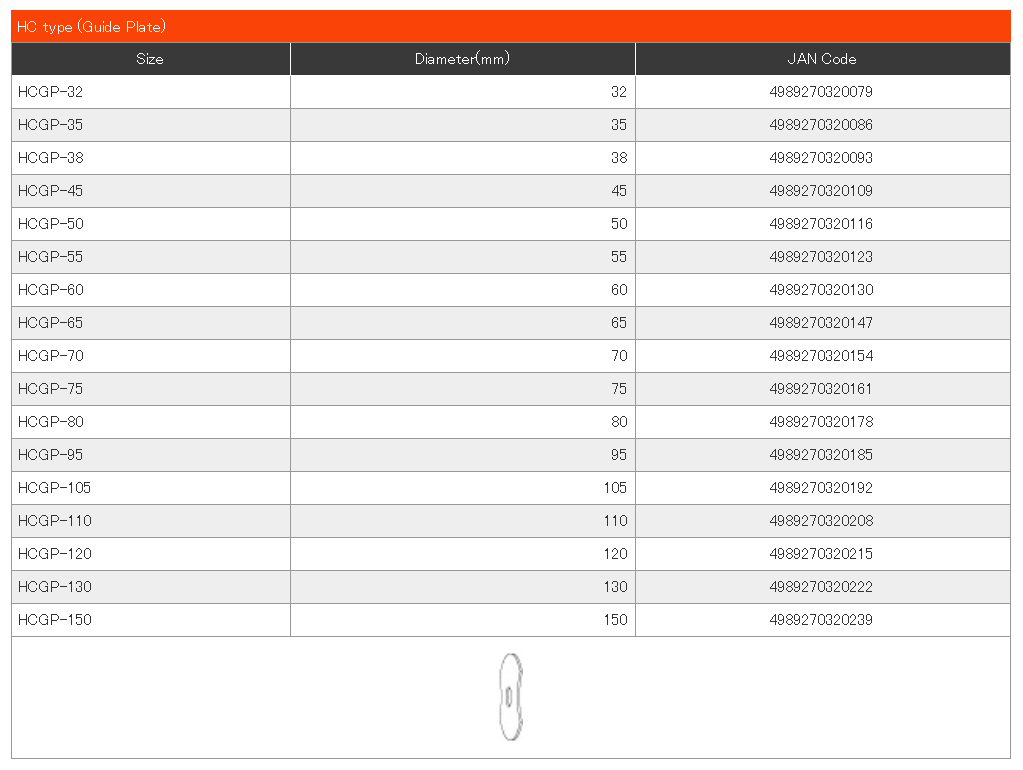

HC Type (Guide Plate)

| Size | Diameter(mm) | Size | Diameter(mm) |

| HCGP-32 | 32 | HCGP-75 | 75 |

| HCGP-35 | 35 | HCGP-80 | 80 |

| HCGP-38 | 38 | HCGP-95 | 95 |

| HCGP-45 | 45 | HCGP-105 | 105 |

| HCGP-50 | 50 | HCGP-110 | 110 |

| HCGP-55 | 55 | HCGP-120 | 120 |

| HCGP-60 | 60 | HCGP-130 | 130 |

| HCGP-65 | 65 | HCGP-150 | 150 |

| HCGP-70 | 70 |

Related Products

-

TONE CB60 Cross Bar

-

Okazaki Seiko SPSED2A Coated Solid Carbide Square Endmills (2 Flutes)

-

SAKUSAKU 4SS-30D 1.0S Carbide Square End Mill 4-Flute

-

KORI SEIKI RS Ratchet Counters Medium Type

-

Chiyoda Seiki Laminated Insulation Vacuum Piping Unit Transfer And Supply Of Cryogenic Fluids

-

Tohnichi Interchangeable Head – FH Hook Head