Drilling And Cutting, Japan, Unika

UNIKA One-touch Meta-core MAX T.C.T Hole Saw

Manufacturer: UNIKA

Model: META-CORE MAX 25[1-touch Type]/ META-CORE MAX 35[1-touch Type]/META-CORE MAX 50[1-touch Type]

■High-precision speed drilling through thick steel plate. Overlap drilling also possible.

■Include unique Unika technology such as 3-angle cutting edges (2-angles for 17mm diameter cutters or less). Low chance of premature tip damage for stable cutter life.

■Quick release cutter mounting and removal.

◆Effective length: 50mm(Max50)/35mm(Max35)

50 mm (MAX50)

◆Applicable Electric Tool: Magnetic Drilling Machine

■Installation explanatory video

USES

STEEL PLATE (HB300 or less)? CAST IRON? STAINLESS STEEL? PIPE MATERIAL

■1-touch & side-lock combination

■Feed speed

| Stainless steel | Common steel | Cast iron |

|---|---|---|

| 0.01 mm/rev | 0.05 mm/rev | 0.08 mm/rev |

■Appropriate rotation speed (Peripheral speed)

Common steel = 40 – 60 m/min. Stainless steel = 20 – 40 m/min. Cast iron = 70 – 90 m/min.

■3-Ply Cutters

Cutting the shavings to one-third with respect to the cutting width using 3-ply cutters (outer, inner and intermediate cutting blades) has dramatically decreased cracks on the tip corner. This also includes inside cutting edges so debris can be discharged smoothly.

■Endurance test

Standard size used: MX50-24.0mm Worked on material: JIS SM490 with 25mm thickness

Power tool: LO-3550A-950RPM (Nitto Koki Magnetic Drill Press)

Other: Manual drilling, water-soluble cutting oil used.

■Compatible Magnetic Drilling Machine (1-touch Type)

| Small size | Manufacturer | Model No. | MX25 | MX35 | MX50 |

|---|---|---|---|---|---|

| NITTO | LO-3000A | ~φ13.5 | ~φ30.0 | ? | |

| LO-3550A | ~φ13.5 | ~φ35.0 | ~φ35.0 | ||

| HiKOKI | BM40M2 | ~φ13.5 | ~φ40.0 | ~φ40.0 |

| Standard size | Manufacturer | Model No. | MX25 | MX35 | MX50 |

|---|---|---|---|---|---|

| NITTO | QA-4000 | ? | ~φ40.0 | ? | |

| QA-6500 | ? | ~φ40.0 | ~φ65.0 | ||

| A-3000 | ? | ~φ30.0 | ? | ||

| A-5000 | ? | ~φ40.0 | ~φ50.0 |

- Pilot pin attachment: Insert the pilot pin that fits the size of the Meta-Core MAX into the MAX body.

- Body attachment: Align white line of power tool sleeve and recess on cutter. Insert to fit. Rotate and listen for “click”.

- Body removal: By rotating the sleeve to the left, the cutter can be removed.

■Compatible Magnetic Drilling Machine (Side Lock Type)

| Small size | Manufacturer | Model No. | MX25 | MX35 | MX50 |

|---|---|---|---|---|---|

| IKURA SEIKI | IS-LB30SX | ~φ13.5 | ~φ30.0 | ? | |

| IS-LB40SW | ~φ13.5 | ~φ40.0 | ~φ40.0 | ||

| IS-LB50SW | ? | ~φ40.0 | ~φ50.0 | ||

| ISK-LB50SX | ~φ13.5 | ~φ40.0 | ~φ50.0 | ||

| OMI | MGF30AH | ~φ13.5 | ~φ30.0 | ? | |

| MGF40AH | ~φ13.5 | ~φ40.0 | ~φ40.0 | ||

| MGF50AH | ~φ13.5 | ~φ40.0 | ~φ50.0 |

| Standard size | Manufacturer | Model No. | MX25 | MX35 | MX50 |

|---|---|---|---|---|---|

| NITTO | FA-35 | ? | ~φ35.0 | ? | |

| FA-50 | ? | ~φ40.0 | ~φ50.0 |

- Pilot pin attachment: Insert the pilot pin that fits the size of the Meta-Core MAX into the MAX body.

- Body attachment: Insert the Meta-Core MAX in a manner that the flat surface of the Meta-Core Max is placed over the threaded portion of the spindle arbor.

- Screw tightening and attachment cross section: Tighten the fixing screw securely with a hexagonal wrench.

SPECIFICATION

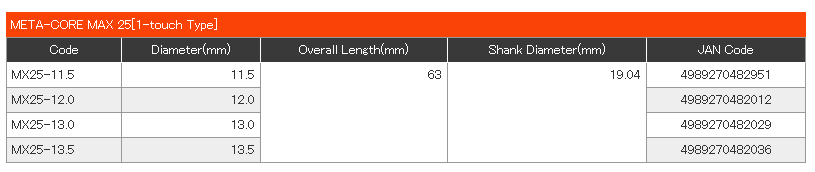

META-CORE MAX 25[1-touch Type]

| Code | Diameter(mm) |

| MX25-11.5 | 11.5 |

| MX25-12.0 | 12 |

| MX25-13.0 | 13 |

| MX25-13.5 | 13.5 |

| Code | Diameter(mm) | Code | Diameter(mm) | Code | Diameter(mm) | Code | Diameter(mm) |

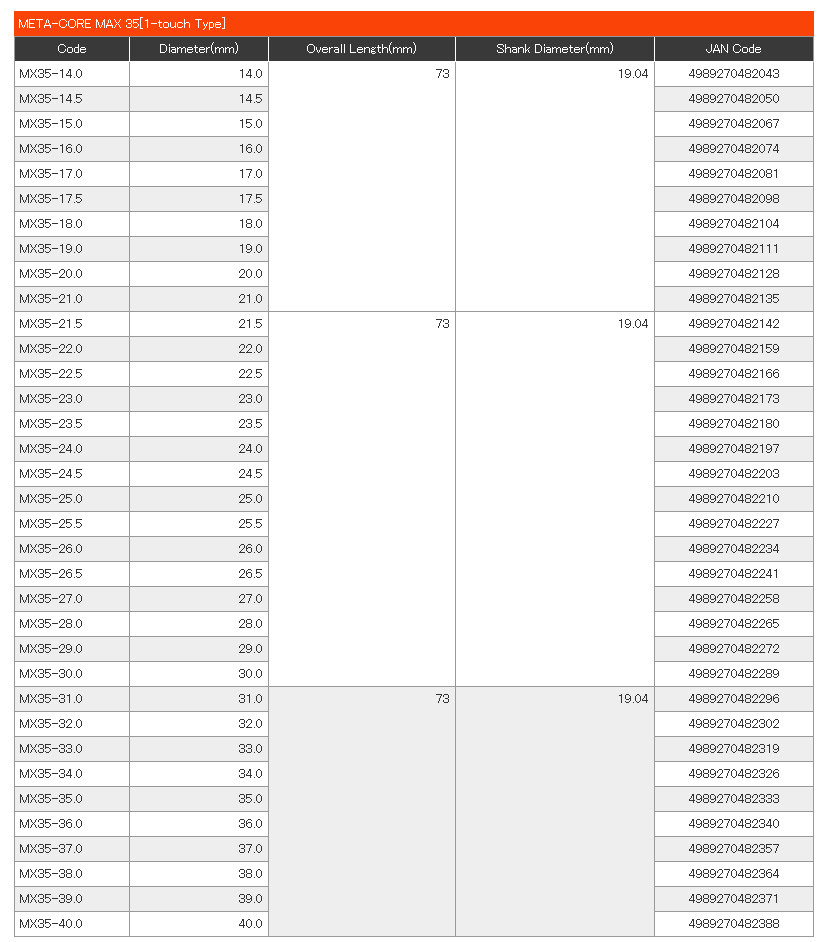

| MX35-14.0 | 14 | MX35-21.0 | 21 | MX35-25.5 | 25.5 | MX35-33.0 | 33 |

| MX35-14.5 | 14.5 | MX35-21.5 | 21.5 | MX35-26.0 | 26 | MX35-34.0 | 34 |

| MX35-15.0 | 15 | MX35-22.0 | 22 | MX35-26.5 | 26.5 | MX35-35.0 | 35 |

| MX35-16.0 | 16 | MX35-22.5 | 22.5 | MX35-27.0 | 27 | MX35-36.0 | 36 |

| MX35-17.0 | 17 | MX35-23.0 | 23 | MX35-28.0 | 28 | MX35-37.0 | 37 |

| MX35-17.5 | 17.5 | MX35-23.5 | 23.5 | MX35-29.0 | 29 | MX35-38.0 | 38 |

| MX35-18.0 | 18 | MX35-24.0 | 24 | MX35-30.0 | 30 | MX35-39.0 | 39 |

| MX35-19.0 | 19 | MX35-24.5 | 24.5 | MX35-31.0 | 31 | MX35-40.0 | 40 |

| MX35-20.0 | 20 | MX35-25.0 | 25 | MX35-32.0 | 32 |

| Code | Diameter(mm) | Code | Diameter(mm) | Code | Diameter(mm) | Code | Diameter(mm) | Code | Diameter(mm) |

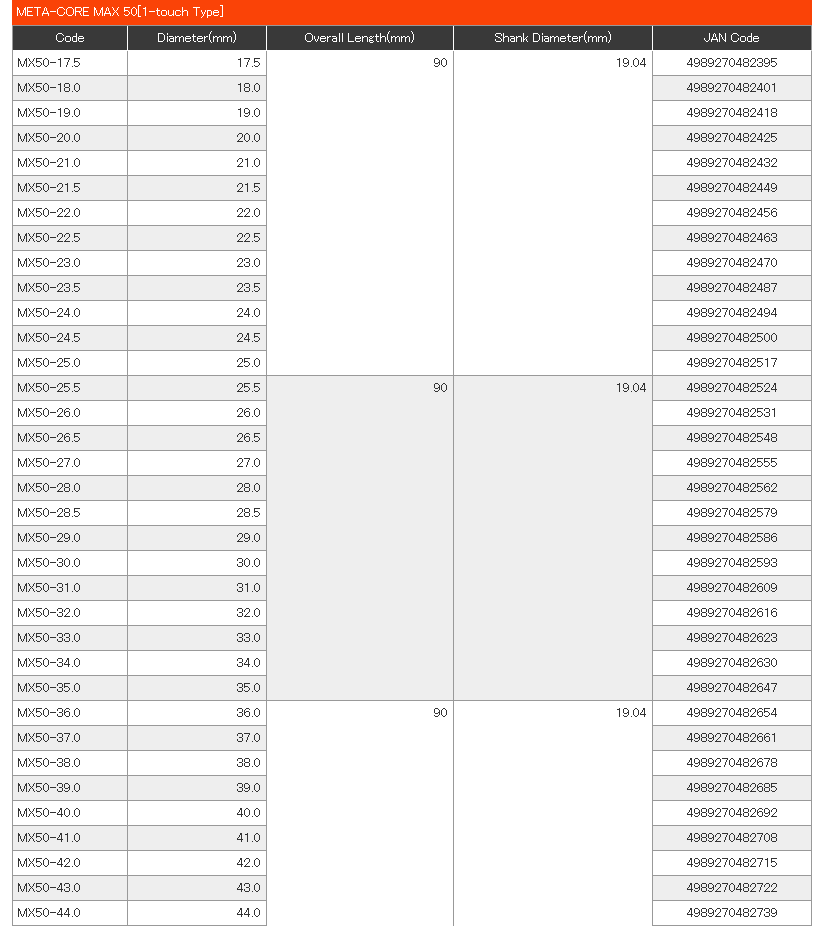

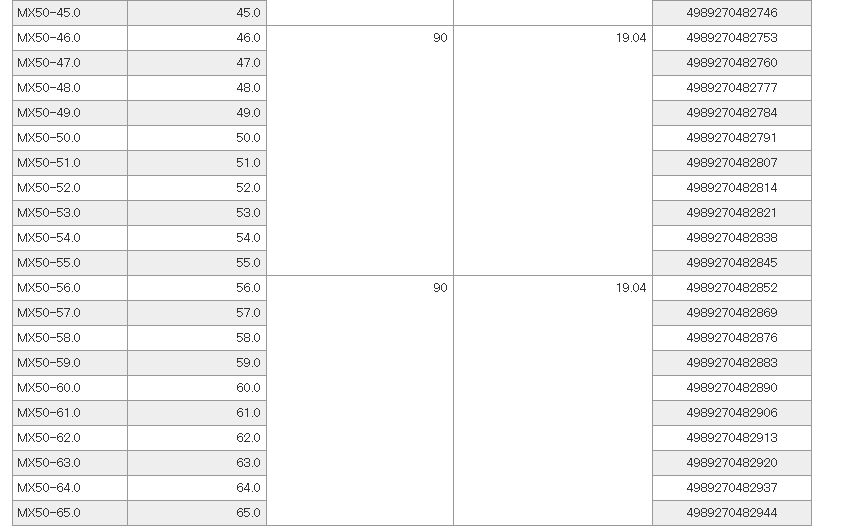

| MX50-17.5 | 17.5 | MX50-24.5 | 24.5 | MX50-32.0 | 32 | MX50-43.0 | 43 | MX50-54.0 | 54 |

| MX50-18.0 | 18 | MX50-25.0 | 25 | MX50-33.0 | 33 | MX50-44.0 | 44 | MX50-55.0 | 55 |

| MX50-19.0 | 19 | MX50-25.5 | 25.5 | MX50-34.0 | 34 | MX50-45.0 | 45 | MX50-56.0 | 56 |

| MX50-20.0 | 20 | MX50-26.0 | 26 | MX50-35.0 | 35 | MX50-46.0 | 46 | MX50-57.0 | 57 |

| MX50-21.0 | 21 | MX50-26.5 | 26.5 | MX50-36.0 | 36 | MX50-47.0 | 47 | MX50-58.0 | 58 |

| MX50-21.5 | 21.5 | MX50-27.0 | 27 | MX50-37.0 | 37 | MX50-48.0 | 48 | MX50-59.0 | 59 |

| MX50-22.0 | 22 | MX50-28.0 | 28 | MX50-38.0 | 38 | MX50-49.0 | 49 | MX50-60.0 | 60 |

| MX50-22.5 | 22.5 | MX50-28.5 | 28.5 | MX50-39.0 | 39 | MX50-50.0 | 50 | MX50-61.0 | 61 |

| MX50-23.0 | 23 | MX50-29.0 | 29 | MX50-40.0 | 40 | MX50-51.0 | 51 | MX50-62.0 | 62 |

| MX50-23.5 | 23.5 | MX50-30.0 | 30 | MX50-41.0 | 41 | MX50-52.0 | 52 | MX50-63.0 | 63 |

| MX50-24.0 | 24 | MX50-31.0 | 31 | MX50-42.0 | 42 | MX50-53.0 | 53 | MX50-64.0 | 64 |

| MX50-65.0 | 65 |

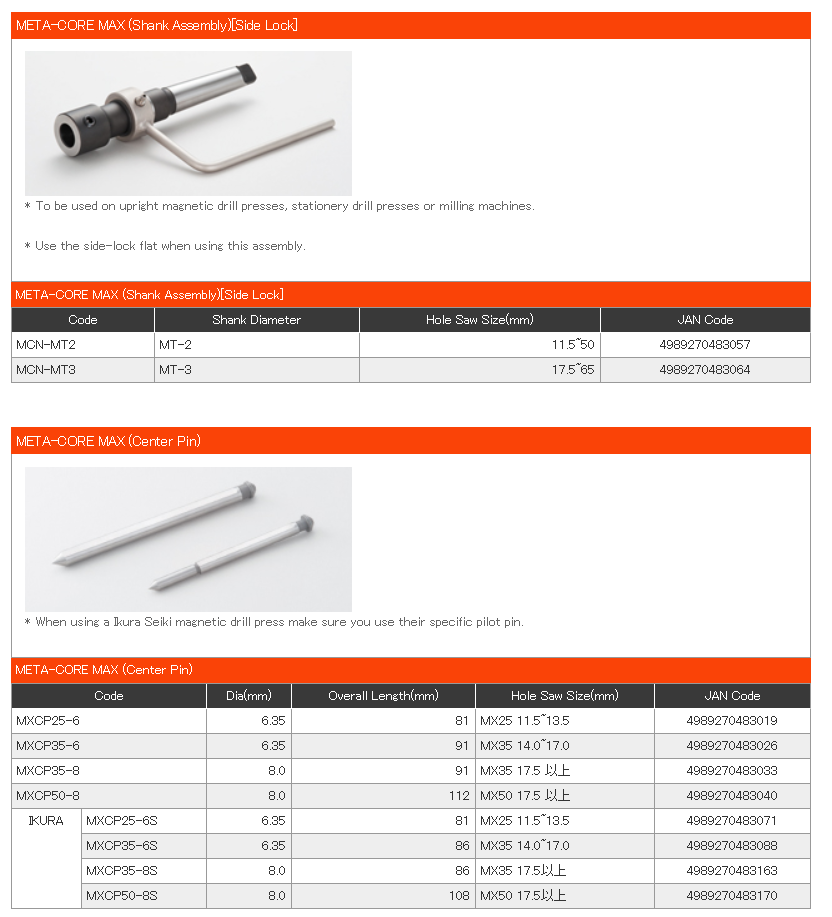

META-CORE MAX (Shank Assembly)[Side Lock] META-CORE MAX (Center Pin)

| Code | Shank Diameter | Code | Dia(mm) | ||

| MCN-MT2 | MT-2 | MXCP25-6 | 6.35 | ||

| MCN-MT3 | MT-3 | MXCP35-6 | 6.35 | ||

| MXCP35-8 | 8 | ||||

| MXCP50-8 | 8 | ||||

| IKURA | MXCP25-6S | 6.35 | |||

| MXCP35-6S | 6.35 | ||||

| MXCP35-8S | 8 | ||||

| MXCP50-8S | 8 | ||||

Related Products

-

Watanabe WPJ Draw-out Protection Tube Special Threaded Type

-

Naniwa PS Turnbuckle Body

-

TAIYO W-A2M25(40) Series Shock Absorber (Two-Stage Motion W Type)

-

Eagle Jack (Konno Corporation) ED-200 Hydraulic Bottle Jack

-

Kunimoto 002062 KS Contact Plate for 60 square pipe (LL Model)

-

Kokosha BXDM751 Desk Light Fluorescent