Yamashina Seiki

Yamashina Seiki Opposed Hollow Facing Machine For Motor Frame Processing

Product Made In Japan

Manufacture: Yamashina Seiki

Model: Hollow Facing Machine

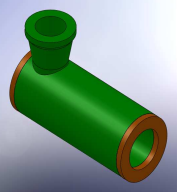

The motor pump’s body (pipe) will undergo machining for its inner diameter, outer diameter, and end surface. To enable machining on both the left and right sides of the workpiece, the machining units are designed to be opposed. Moreover, due to the characteristics based on the workpiece standard, the setup allows for internal clamping with a collet by making the mandrel pass through, achieving a hollow design. This ensures stable machining. Additionally, each of the left and right units is equipped with an ATC (Automatic Tool Changer) to accommodate a variety of workpieces.

Machine in General

- Floor Space: 8200mm x 1325mm x 2480mm

- Total Weight: 18000Kg

- Hollow Facing Machining Unit (Opposed Type):

- Movement Unit: X-axis, Z-axis

- Hollow Facing:

- (X-axis): Stroke / 75mm

- (Z-axis): Stroke / 650mm

- Both left and right units have the same specifications.

- Ancillary Equipment:

- C-axis Mandrel Work Clamp: Stroke / 650mm

- Sub-clamp: Dual-sided vice

- Work Positioning: Opposing C-axis Mandrel Clamp

- ATC Magazine: 12 tools per unit

- Fixture: V-receiving pad (for lower cylinder)

- Machining Reference: Touch Probe (Stylus)

- Work Loading: Manual (overhead crane)

- Coolant: None

- Chip Conveyor: 2 units, chip removal capacity: 35L/min

- Hydraulic Unit: 2 units

- 100L (for 7MPa line), 60L (for 10MPa line)

- Semi-Full Cover: Equipped with safety door switch

Target Workpiece

- Outer Diameter: φ209 to φ381

Length: 3500 to 1200L

Material: SUS304, SS400

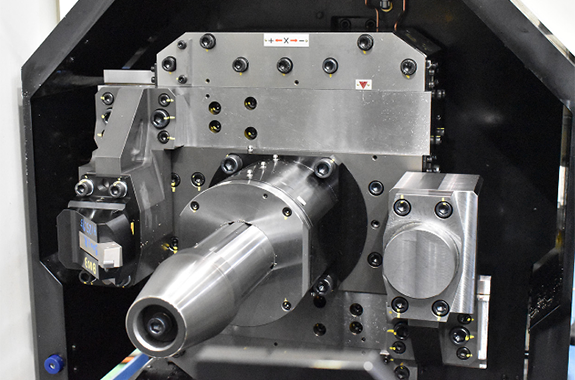

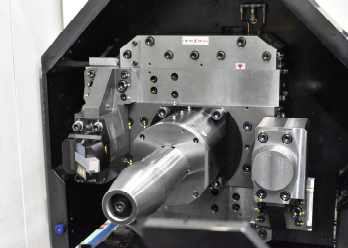

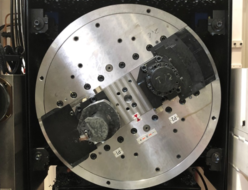

Machine Photos

- Hollow Facing Front Panel

- ATC Magazine with 12 Slots

- Fixtures (Main: Mandrel / Sub: V-Clamp)

- Machine Exterior (Front)

- Differential Gear (Behind the Machining Unit)

- Machine Exterior (Rear)

Related Products

-

Yamashina Seiki Dedicated Boring Machine For Finishing Holes on Both Ends of Large Connecting Rods

-

Yamashina Seiki Air Extractor

-

Yamashina Seiki 2-Spindle Vertical Machining Center With U-axis Control Function

-

Yamashina Seiki Opposite 500 2-pod Type CNC Facing Machine

-

Yamashina Seiki e-DRAIN Drain Cooler

-

Yamashina Seiki Electromagnetic Timing Lubrication EDL System