EIKOH, Japan

EIKOH Quartz Glass

Made in Japan

Manufacturer: Eikoh Co., Ltd.

There are three types of quartz glass: transparent quartz glass made from fused natural quartz, opaque quartz glass made from fused high-quality silica, and synthetic quartz glass made from high-purity silicon tetrachloride. Quartz glass, whose main component is pure fused SiO2, has many properties, including high purity, chemical stability, heat resistance, light transmittance, and electrical insulation. For these reasons, it is widely used as an indispensable material in various industrial fields, including the semiconductor industry, lighting, home appliances, and optics. We

process this quartz glass into shapes that meet the various needs of our customers while maintaining its high purity.

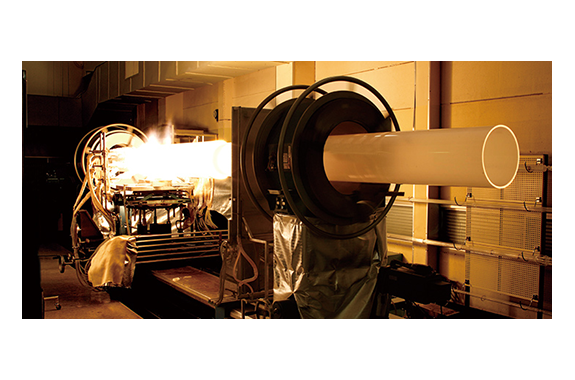

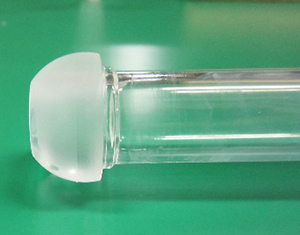

Examples of flame processed products

In recent years, there has been an increase in requests for large-diameter processed products made of quartz glass in semiconductor and liquid crystal manufacturing processes (oxidation, diffusion, LPCVD, annealing, etc.). With 12-inch wafer sizes becoming mainstream and φ450mm products being developed, the range of uses is becoming wider, including large furnace tubes and large chambers made of transparent quartz.

In order to handle large-diameter products, our factory has installed dedicated machines and possesses the technology to freely mold products to any diameter. Our

experienced staff will make the necessary suggestions for production and provide you with a satisfactory product while maintaining confidentiality with our customers.

Large Quartz Bell Jar

Processing results:

Outer diameter 700mm, thickness 6mm, length 1500mm

Outer diameter 880mm, thickness 7mm, length 1000mm

The sealed area is not made by laminating plates, but by sealing a straight tube, and the radius of the sealed area can be made to any desired radius.

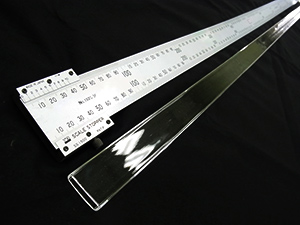

Quartz Square Tube

Quartz tubes are processed into square shapes using a special forming method.

In addition to square shapes, oval shapes can also be processed.

Special welding products

The boards are attached together using a special method that does not use adhesives.

The flatness of the plate surfaces is excellent when they are laminated, so there is no need to re-polish the surfaces after lamination.

It is chemical resistant and can be used at high temperatures, without impairing the transmittance of the bonded area.

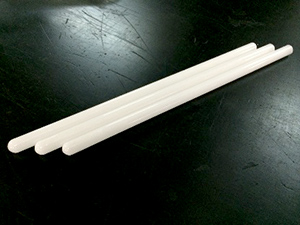

Opaque Quartz Processing

Although domestic manufacturers have almost completely stopped producing opaque quartz tubes, they are still used today as materials for quartz heaters, etc.

Our company procures materials through its own unique route.

We also handle high-purity block materials.

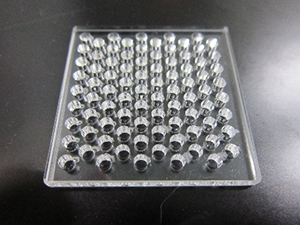

Examples of cut and grinded products

High-purity quartz glass is hard and brittle, just like other common glass materials.

In order to meet the demand for high-precision processing of this difficult-to-cut material, our factory has introduced a gliding center, NC surface grinding machine, and cylindrical grinding lathe equipped with diamond tools of various shapes, enabling grooving, drilling, cylindrical and surface grinding, thread cutting, and other shapes.

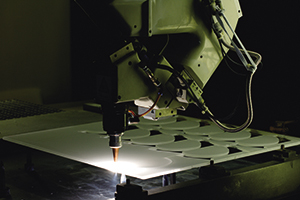

CO2 3D laser processing

Although the processing precision is inferior to that of machining, it is effective for continuous drilling and cutting of quartz tubes.

- Compatible work size: 1000 x 900 x 500 (H) (mm)

- Maximum processing thickness: 10mm

- Minimum hole size: φ0.3mm

- The outer surface of the pipe can also be machined.

Grinding

Machining at a machining center allows for precision that rivals that of metal products.

Both male and female threads can be threaded

. It is also possible to process the threads into joints for use with fluids such as liquids and gases.

- Male thread grinding

- Compatible standards: M screws, RC screws

- Ball joints compatible with mm and inch standards

- Taper fitting 1/5 1/10 taper

- Also available for vacuum grinding

Cylindrical grinding

Cylindrical grinding is possible from small to large diameters. Costs can be reduced by machining only the necessary parts to ensure a sealing surface.

Cylindrical grinding results (maximum size) φ400 to φ800. Sizes

below φ400 can also be handled with medium and small grinding lathes (up to φ4mm).

Inspection Equipment

We also focus on inspection equipment to meet the various needs of customers for quartz glass processed products, which are each handcrafted.

Using contact and projection type three-dimensional measuring devices, we promise to provide reliable data on geometric tolerances and multi-point measurements.

Inspection Equipment

- 3D measuring device (contact type)

- 3D measuring device (projection type)

- Surface Roughness Measuring Instrument

- Optical microscope

- UV-Visible Spectrophotometer

- Thermography

- Interferometric strain gauge