Fukudaco, Japan

Fukudaco Aegis SGR Low Voltage Motor Protection

Manufacturer: Fukudaco

Overview

Aegis® SGR effectively prevents premature bearing damage, such as electrical discharge machining (EDM) and grease degradation. Designed specifically for low-voltage motors under 375 kW, this solution addresses bearing current issues efficiently. Additionally, for high-voltage motors or those exceeding 375 kW (225 kW for DC motors), we recommend the Aegis® PRO Ring for optimal performance. By implementing Aegis® Rings, you can significantly enhance motor longevity and reliability.

Applications

- Bearing protection and lubrication degradation prevention for inverter motors (addressing electrical discharge machining and bearing current issues)

- Servo motors and thyristor-controlled DC motors

- Noise reduction in electric vehicles (RFI noise and EMI noise mitigation)

- Pumps, turbines, gearboxes, extruders, speed detectors, etc.

- Gantry cranes, belt conveyors, data center air conditioning, and more

Features

- Maintenance-free and long-lasting

- Available in both one-piece and split versions, allowing for installation even with couplings or pulleys attached

- Compatible as an option with various motor manufacturers

- Widely adopted in industrial motors, steam turbines, electric vehicles, and more

- Experienced Aegis® installation partners (motor maintenance companies) available for referrals

Aegis® SGR Type

Clamp-Fixed Type

Secure the Aegis® Ring with the included clamps (mounting legs), bolts, and washers. Known as the bracket type, the one-piece design provides robust stability. Meanwhile, the split type, also referred to as the split type, offers versatile installation options. With these components, installation becomes seamless and reliable.

Specifications:

- Shape: One-piece, split type

- Shaft Diameter: 7.9 to 152.9 mm*1

- Included Items: Aegis® Ring, hex socket head bolts (M3x0.5x8mm), washers*2

- Model Examples: One-piece: SGR--2, Split type: SGR--2A4

Important Notes:

- For this type, fill the blank space with the fiber’s inner diameter, not the shaft diameter. Please refer to the model number table for more details.

- We can also accommodate larger shaft diameters, so please contact us for additional information.

- Secure the one-piece type at 2-3 points. For the split type, secure at 4 points for shaft diameters up to 60.8mm and at 6 points for shaft diameters 60.9mm and above.

Bolt-Through Type

Secure the Aegis® Ring directly with the included bolts, eliminating the need for mounting legs (brackets). This method allows for a smaller bolt circle diameter (BCD), enhancing efficiency and ease of installation. Enjoy the streamlined process and improved performance with this convenient setup.

Specifications:

- Shape: One-piece, split type

- Shaft Diameter: 7.9 to 152.9 mm*1

- Included Items: Aegis® Ring, countersunk screws (M3x12mm)*3

- Model Examples: One-piece: SGR-___-3MFH, Split type: Please consult us

Important Notes:

- For this type, fill the blank space with the fiber’s inner diameter, not the shaft diameter. Please refer to the model number table for more details.

- We can also accommodate larger shaft diameters. Please contact us for additional information.

- For shaft diameters up to 86.2mm, secure at 2 points. For shaft diameters 86.3mm and above, secure at 4 points. You can also use hex socket head bolts (M3x14), which will change the model number from “-3MFH” to “-3.”

Conductive Epoxy Type

The Aegis® Ring is secured using the included conductive epoxy resin, making it ideal for motors where bracket bolt-hole drilling or tapping is not possible. The mounting surface paint is removed, and the ring is fixed with conductive epoxy resin.

Specifications:

- Shape: One-piece, split type

- Shaft Diameter: 7.9 to 152.9 mm*1

- Included Items: Aegis® Ring, conductive epoxy resin (EP2400)

- Model Examples: One-piece: SGR--0AW, Split type: SGR--0A4W

*Note: For this type, the blank space is filled with the fiber’s inner diameter, not the shaft diameter. Please refer to the model number table for details. *1 Larger shaft diameters can also be accommodated. Please contact us for details.

The Aegis® Ring is secured using the included four types of mounting legs and bolts. The brackets can be used to avoid shaft keys, key slots, and stepped shaft sections. It can also be fixed using the separately sold conductive epoxy (model: EP2400), making it ideal for motor maintenance and bearing replacement.

Recommended for all motors where Aegis® Rings are installed. Improves the conductivity of the shaft surface, enhancing the effectiveness of the grounding ring.

- Model Number: CS015

- Quantity: 15g (sufficient for approximately 20 applications on a 75mm shaft)

- Storage: 6 months (store in a cool place; mix well before use as the components may separate over time)

- Caution: Use protective equipment.

Conductive Epoxy Resin EP2400

When installing Aegis® Rings, if drilling or tapping holes is not possible, use conductive epoxy to bond and secure the ring.

- Model Number: EP2400

- Quantity: 7g each (used by mixing the two tubes)

- Storage: 9 months (store in a cool, dry place below 25°C; keep away from high temperatures, fire, or flames)

- Usage:

- Remove any paint or materials that might impede conductivity on the mounting surface.

- Mix the two resins and quickly apply them to bond the ring.

- At temperatures above 24°C, the epoxy sets in about 4 hours. Using a heat gun, it can set in about 10 minutes at 66-121°C.

- Caution: Use protective equipment when handling.

The Aegis® Ring is secured by press fitting.

Specifications:

- Shape: One-piece

- Shaft Diameter: 7.9 to 152.9 mm

Related Products

-

Fukudaco Perlast FFKM and Perlast ICE Low-Temperature FFKM Seals

-

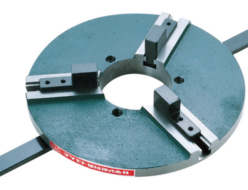

Matsumoto Kikai WP200 ~ 400 / WPT600 ~ 1500 Welding Chuck (for Cylindrical Shape Only)

-

Vessel No.NMS-2PG Magnet Catcher Short (Green)

-

Kanetec KPM-BW PLATE MAGNET FOR TANK CLEANING

-

ELEPHANT (Zojirushi) WF Series Screw Clamp

-

Nakatani Kikai NC0AS Spring Type Mini Chipping Hammer (Clutch Type)