Fukudaco, Japan

Fukudaco Aegis Grounding Ring

Manufacturer: Fukudaco

Overview

Developed by Electro Static Technology in the USA, the Aegis® Grounding Ring is a maintenance-free shaft grounding solution. It protects bearings and lubrication from shaft voltage caused by inverter control.

Applications

- Bearing protection and lubrication degradation prevention for inverter motors (addressing electrical discharge machining and bearing current issues)

- Servo motors and thyristor-controlled DC motors

- Noise reduction in electric vehicles (RFI noise and EMI noise mitigation)

- Pumps, turbines, gearboxes, extruders, speed detectors, and more

- Gantry cranes, belt conveyors, data center air conditioning, and other industrial applications

Features

- Maintenance-free and long-lasting

- Available in both one-piece and split versions, allowing for installation even with couplings or pulleys attached

- Compatible as an optional feature with various motor manufacturers

- Widely adopted in diverse fields, including industrial motors and electric vehicles

- Access to experienced Aegis® installation partners (motor maintenance companies) for reliable support

How to Select Aegis® SGR / Aegis® PRO Rings

Step 1: Confirm Motor Output and Input Voltage

Check the motor’s output and input voltage. The voltage components generated by the motor vary based on its output. Therefore, the countermeasures differ depending on the motor’s output and voltage.

Table 1: Required Bearing Current Countermeasures

| In the case of AC motors | ~ 75 kW (low voltage motor) | 75 to 375 kW (low voltage motor) | 375 kW or more (600 V or more) |

|---|---|---|---|

| In the case of a DC motor | ~ 7.5 kW (low voltage motor) | 7.5 to 225 kW (low voltage motor) | 225 kW or more (600 V or more) |

| Bearing Current Components | EDM Current Due to Capacitance | Capacitive EDM current + high-frequency circulating current | Capacitive EDM current + High frequency circulating current + Low frequency circulating currents |

| Load side | Aegis® SGR | Aegis® SGR | Aegis® PRO |

| Non-load side | Insulated bearings and shaft insulation (to cut off circulating currents) | Insulated bearings and shaft insulation (to cut off circulating currents) |

Aegis® SGR and Aegis® PRO

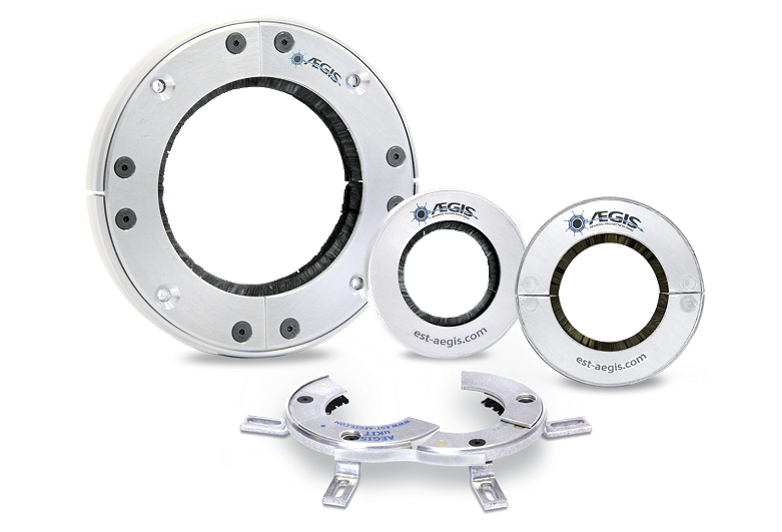

Aegis SGR (left) and Aegis PRO

Table 2 Aegis SGR and Aegis PRO

| Aegis® SGR | Aegis® PRO | |

|---|---|---|

| AC motor: less than 375kW and less than 600V DC motor: less than 225kW | Applicability criteria | AC motor: Over 375kW or over 600V DC motor: Over 225kW |

| 2 layers | Conductive Fiber | 6 layers |

| 7.9 to 152.9 | Shaft diameter [mm] | 63.5 to 762 |

| Integrated/Separate | Ring Shape | Integrated/Separate |

| Bolt fixing (M3/M4) Conductive epoxy fixing Press-fit fixing | Fixing Method | Bolt fixing (M4) Special bracket “BKT-PRO-2 (sold separately)” (M8) press-fit fixing |

| 7.5 | Maximum ring thickness [mm] | Integrated-type 15.88 Split type 16.51 |

| Check the catalog | Ring outer diameter [mm] | Shaft diameter + 47.24 |

| Check the catalog | Bolt hole BCD [mm] | Shaft diameter + 28.95 |

Step 2: Check the shape of the shaft and motor bracket.

Choose the Aegis® Ring model that matches the shaft diameter at the installation point. Ensure you do not install the ring on uneven surfaces, such as shaft steps or keyways, as this can damage the conductive microfiber.

If your shaft has steps or keyways, follow these guidelines:

- For low-voltage motors under 375 kW (or DC motors under 225 kW), use the Aegis® SGR uKIT.

- For high-voltage motors or motors above 375 kW (or DC motors above 225 kW), please contact us for further assistance.

Additionally, if the shaft has any coatings that hinder conductivity, remove these coatings. Then, apply silver paint (P/N: CS015) to maintain the conductivity of the shaft surface, which is crucial for effective performance.

By carefully following these steps, you ensure that your motor receives the optimal protection and performance enhancement from the Aegis® Ring. Contact us for more information or assistance in selecting the appropriate model.

Step 3: Shaft Insulation on the Non-Drive End

If your motor requires shaft insulation and it is not insulated, replace the non-drive end bearing with an insulated bearing, such as INSUTECT®.

Related Products

-

Gentos Explorer EX-434B LED Lantern

-

TONE RH4CH Ratchet Handle, Compact Head (Socket Hold Type)

-

Hasegawa Electric HLA-N2 DC Voltage Detector Checker (Handy type)

-

TONE 3S-L120 Deep Socket

-

Watanabe A6000 Series A6□□9 Digital panel meter for frequency/pulse measurement

-

Naniwa SC Shackle Standard Shackle