Fukudaco, Japan

Fukudaco SmartCheck Condition Monitoring Device

Manufacturer: Fukudaco

Model: SmartCheck

Overview

SmartCheck is a condition-monitoring device that monitors vibration and temperature. By detecting the specific vibration frequencies associated with mechanical element failures, it can identify abnormal vibrations that could lead to unexpected equipment shutdowns and pinpoint the malfunctioning mechanical components.

Applications

- Condition monitoring of various production equipment (rotating machinery)

- Pumps

- Motors

- Fans

- Gearboxes

- Belts

- Compressors

- Vibrating screens

Features

- Condition monitoring through a wide range of vibration (0.8–10kHz) and temperature (-20°C to +70°C)

- Automatic FFT analysis with two-stage alarm notification

- Preloaded with numerous measurement templates to cover various production equipment

- Alarm thresholds are adjustable to match operating conditions, even with variable speed and load fluctuations

Benefits of Vibration Condition Monitoring

In bearing damage, which often causes production equipment downtime, the operational status generally changes in the following order:

- Vibration

- Unusual noise

- Temperature rise

- Bearing seizure

Therefore, monitoring vibrations enables the earliest detection of equipment abnormalities.

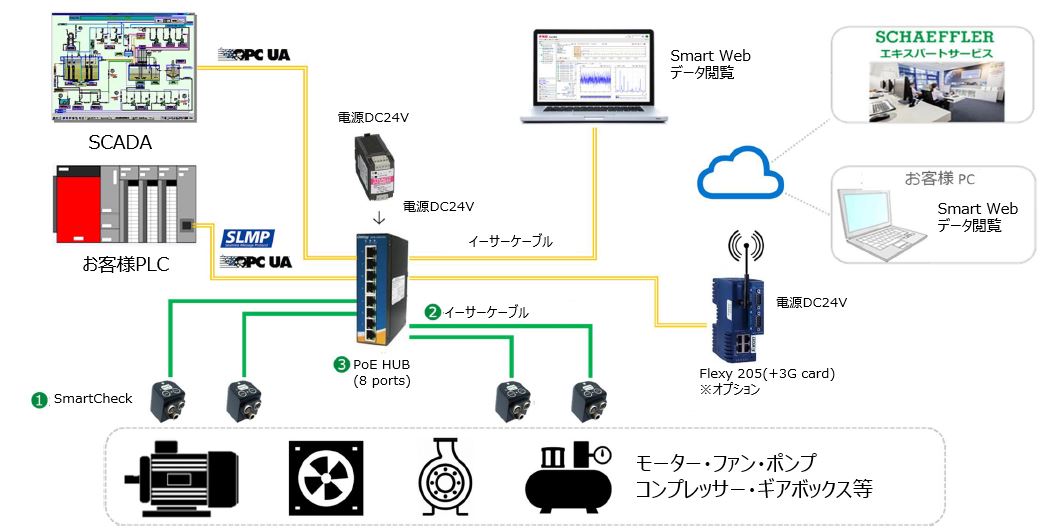

Equipment Monitoring Network Connection Example

Specification

| Measurement | Detection target | Vibration and temperature |

| Frequency Measurement Range | 0.8Hz to 10kHz | |

| Temperature Sensor Measurement Range | -20℃ to +70℃ | |

| Sensors | Internal Specifications | 1-axis piezo acceleration sensor + temperature sensor |

| Operating temperature limit | -20℃ to +70℃ | |

| Protection rating | IP67 | |

| Body dimensions | 44mm x 57mm x 55mm | |

| Installation Method | 4 types of installation methods: ① Screw-in ② Magnet ③ Taper adapter ④ Adhesive | |

| Others | Power supply | DC 16-32 V or PoE (Power over Ethernet) |

| Communication protocol | SLMP OPC-UA |

Related Products

-

Saitama Seiki U-TOOL U-75A Oscillation Sander

-

Seiwa E01P23 Special Mounting EMC Products

-

Kokosha KKS-A0-12 A0 Class Fire-resistant Windows Side Scuttles Welded Type

-

Naniwa RB Shackle Lightweight Shackle

-

NAGANO KEIKI AN10 Low Pressure Gauges Industrial Machines

-

Kunimoto 1301210 KS U-shaped Clamp Fixed Type 2