Fukuda Seiko, Japan

Fukuda Carbon Graphite Damping Composite

Made in Japan

Manufacturer: Fukuda Seiko

Model: Carbon Graphite Damping Composite

Features

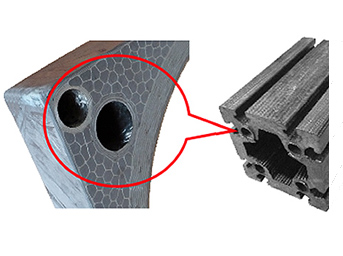

CompoTech’s carbon-graphite composite is a new material produced from 3D cellular composites – 3D polyspicular composites with patented manufacturing methods.

3D cellular composites are composites made by wrapping graphite fibers with carbon fibers and forming them into cells, which has the effect of dispersing stress.

CompoTech’s manufacturing technology is theoretically capable of modifying the mechanical properties of composites according to the application.

- Lighter weight and higher damping than steel

- Excellent torsional stiffness against combined loads

- It is resistant to temperature changes and has a linear expansion coefficient of “1/10 or less than iron”

- Components can be reduced in weight, reducing motor power and increasing speed and acceleration

- Enables energy-saving design and lowers system costs

use

- It is possible to design and manufacture according to the required specifications for various applications.

3 Outstanding Specialties

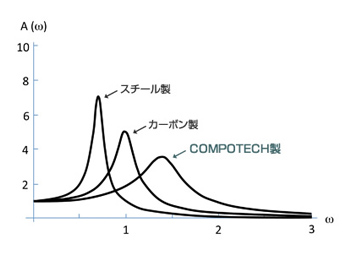

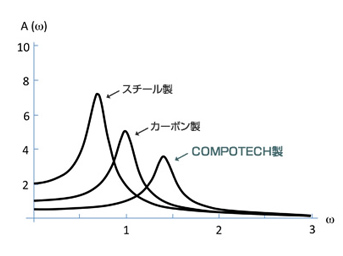

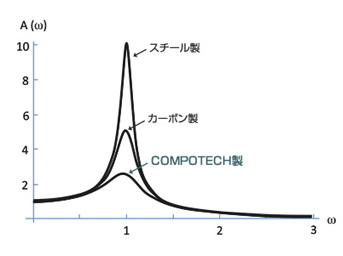

COMPOTECH’s carbon-graphite damping composites have three superior mechanical properties compared to steel:

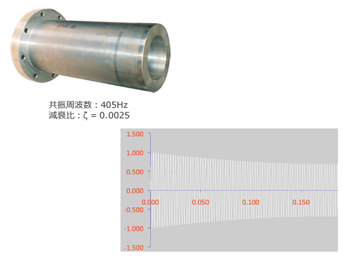

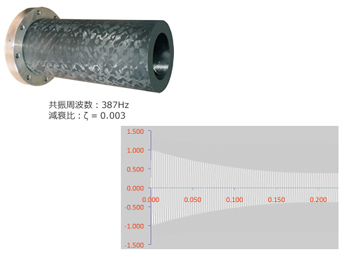

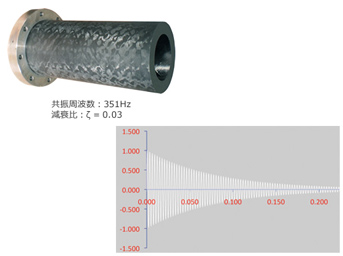

1. Mass

The reduction in mass reduces the amplitude and increases the resonant frequency.

2. Static rigidity

The amplitude is reduced by improving the static rigidity, and the resonant frequency is increased.

3. Attenuation

The amplitude is reduced by improving the damping, and the phase characteristics are smoother.

Special comparison of steel and composites

Comparison Criteria

Steel housing

Carbon housing

Compo Tech Housing

Compared to steel, CompoTech’s carbon-graphite damping composites are lighter, more damping, and more torsionally rigid under compound loads. In addition, it is resistant to temperature changes and has a linear expansion coefficient of “less than 1/10 of iron”. It is possible to reduce the weight of the part, reduce the power of the motor, and increase the speed and acceleration. Energy-saving design is possible to reduce system costs.

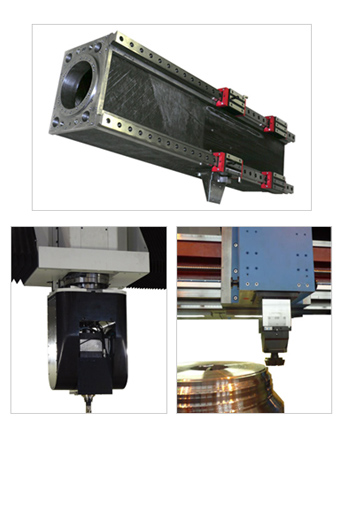

CompoTech Carbon Graphite Damping Composite Applications

COMPOTECH Carbon Graphite Damping Composites are designed and manufactured according to the application and required specifications.

High-rigidity T-slot

It has been adopted for presses and has improved productivity by more than 40%.

High-speed spindle shaft

In-house development of high-speed rotor. Evaluation tests of 100,000 min-1 or more.

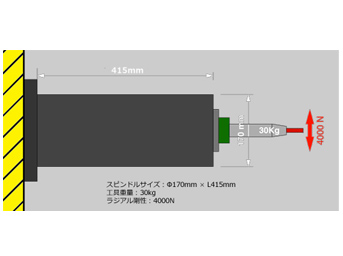

Spindle shaft

We purchased a shaft designed exclusively for our company.

It is built into a test spindle and tested against a steel shaft. Confirmed shaft elongation “less than 1/10 of iron”.

Zero-shaft elongation tube

Development of tubes with zero linear expansion coefficient using the characteristics of graphite fiber and epoxy resin

column

A number of projects are underway for the use of machine columns, heads and spindles.

Skoda (Czech Republic) and PAMA (Italy) use this material.