Drilling And Cutting, Japan, Unika

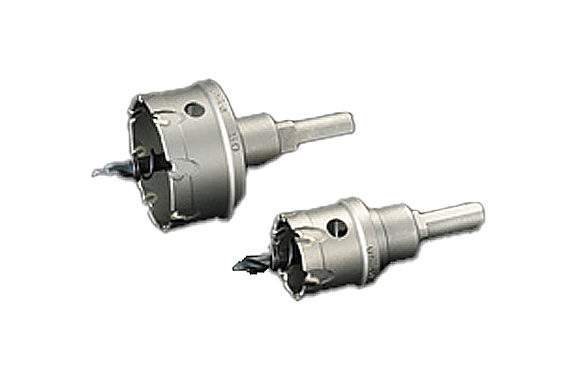

UNIKA Meta-core Triple TR T.C.T Hole Saw

Manufacturer: UNIKA

Model: T.C.T. hole saw Meta-core TR (MCTR Type)/ Center drill (HSS)/ Ejector Spring/ Meta-core TR (Tool Box Set)

■3-ply cutters reducing tip crack even with hard use. Realizes light and speedy drilling and long lifetime.

■The 25mm effective depth enables drilling ranging from thick steel plate to curved face drilling in thick metal pipes.

■Adopts the step center drill that dampens impacts that occur when the center drill passes through.

◆Effective length: 25mm(Full depth: 25 mm)

◆Matching Drill: Electric drill/drilling machine/Percussion drill(rotating mode)

◇Ejector spring fitted as standard/compatible with pipes and stainless steel

■Product promotion video

USES

Sheet metal (HB200 or less)• Stainless steel (10mm ore less)• Pipe• Aluminum (5mm ore less)• FRP• PVC• Plastic

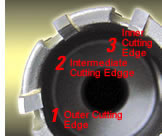

■3-Ply Cutters

Cutting the shavings to one-third with respect to the cutting width using 3-ply cutters (outer, inner and intermediate cutting blades) has dramatically decreased cracks on the tip corner. This also includes inside cutting edges so debris can be discharged smoothly.

■Compatible with Pipe-Drilling

Pipes and curved-surface materials can be drilled at a throat depth of 25 mm.

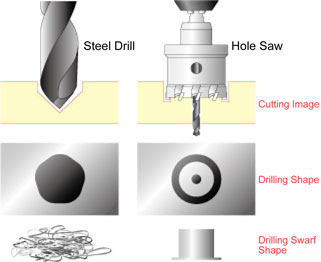

■Hole Saw Drilling Efficiency

Hole saw drilling has a smaller cutting area compared to steel drills, enabling short-time drilling.

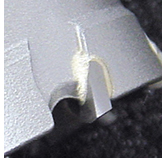

■Drilling swarf discharge groove

Drilling swarf is efficiently discharged through the discharge grooves that are also compatible with thick steel plates. Clogging of drilling swarf between the work material and cutting edge makes drilling impossible, which leads to tips cracking and chipping.

■Shavings Escape Hole

An escape hole, which is convenient for shavings removal, is equipped with hole saws of all diameters.

After removing the main unit from the motor, insert the metal rod that fits through the hole, etc., into the shavings escape hole and push out debris.

After removing the main unit from the motor, insert the metal rod that fits through the hole, etc., into the shavings escape hole and push out debris.

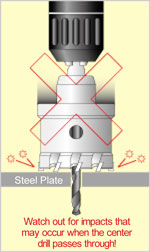

■Newly developed step center drill

Two-step structure of the center drill tip dampens impacts that occur when the center drill passes through, preventing cracking of the tungsten carbide/ultra-hard tip.

■10 mm/13 mm chuck combination shank Allows for most drill chuck diameters.

■Appropriate Rotation Speed

- ■Use the drill at a rotation speed appropriate for the drilling work material and diameter.

- ■When drilling a thick plate with a thickness of 5 mm or more or for continuous cutting, select a lower rotation speed.

■Peripheral Speed

| Stainless Steel | Common Steel | Aluminum |

|---|---|---|

| 25-35 m/min | 40-60 m/min | 60-100 m/min |

- Securely chuck the three-surface section of the shank to prevent swinging or falling.

- Do not reduce the rotation speed excessively during drilling. Jamming or tip cracking may result.

- Do not hit the cutting edges of the tungsten carbide/ultra-hard tip against any hard object or allow strong contact with the work material that may occur when the center drill passes through. The tip will crack.

- In the case of continuous drilling using a drilling machine, watch out for overheating of the cutting edge and use cutting fluid or stop drilling to cool the cutting edge.

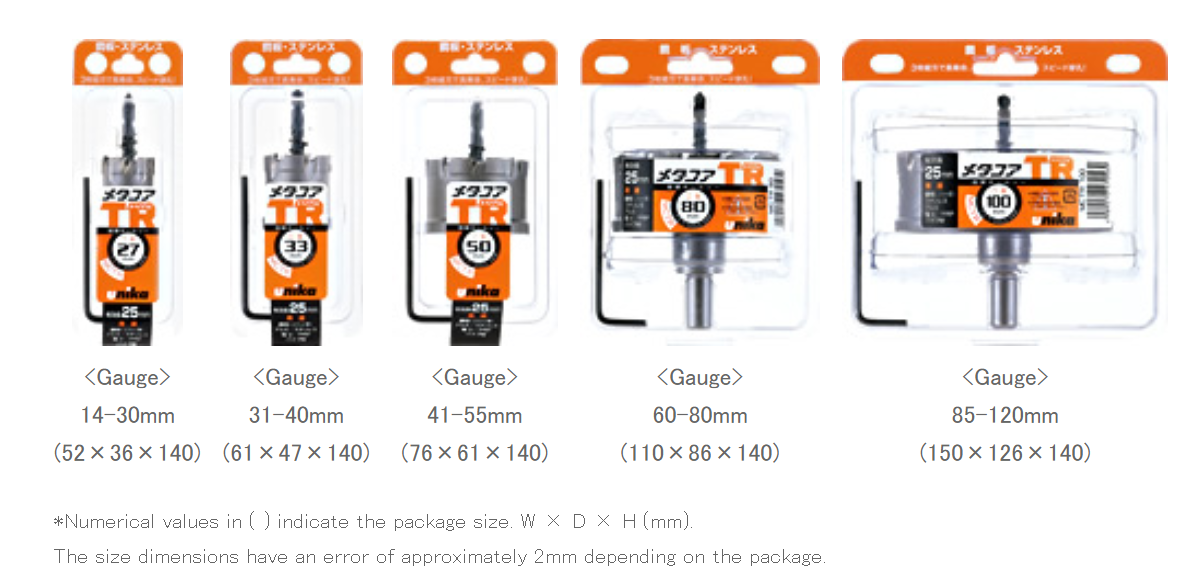

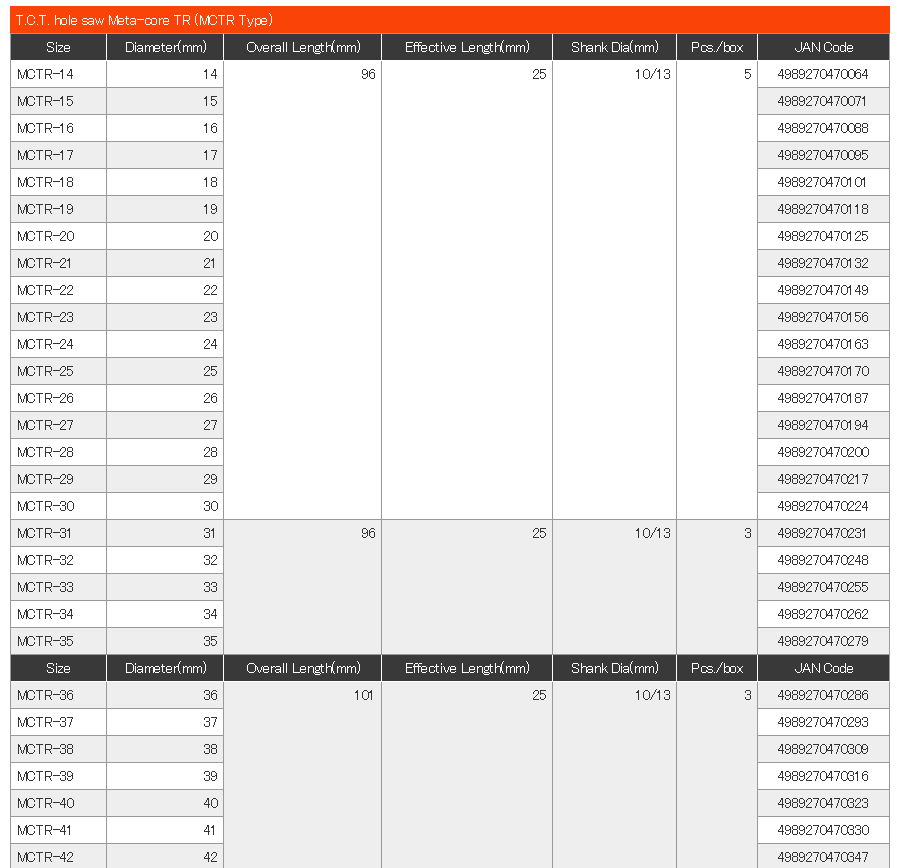

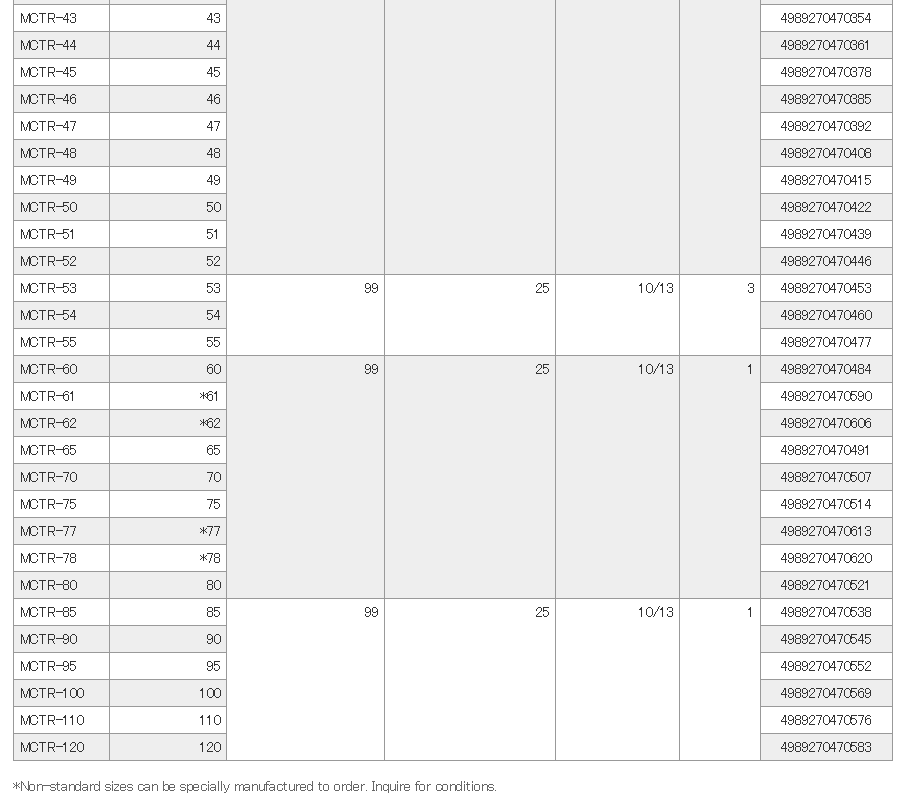

SPECIFICATION

T.C.T. hole saw Meta-core TR (MCTR Type)

| Size | Diameter(mm) | Size | Diameter(mm) | Size | Diameter(mm) | Size | Diameter(mm) |

| MCTR-14 | 14 | MCTR-25 | 25 | MCTR-36 | 36 | MCTR-47 | 47 |

| MCTR-15 | 15 | MCTR-26 | 26 | MCTR-37 | 37 | MCTR-48 | 48 |

| MCTR-16 | 16 | MCTR-27 | 27 | MCTR-38 | 38 | MCTR-49 | 49 |

| MCTR-17 | 17 | MCTR-28 | 28 | MCTR-39 | 39 | MCTR-50 | 50 |

| MCTR-18 | 18 | MCTR-29 | 29 | MCTR-40 | 40 | MCTR-51 | 51 |

| MCTR-19 | 19 | MCTR-30 | 30 | MCTR-41 | 41 | MCTR-52 | 52 |

| MCTR-20 | 20 | MCTR-31 | 31 | MCTR-42 | 42 | MCTR-53 | 53 |

| MCTR-21 | 21 | MCTR-32 | 32 | MCTR-43 | 43 | MCTR-54 | 54 |

| MCTR-22 | 22 | MCTR-33 | 33 | MCTR-44 | 44 | MCTR-55 | 55 |

| MCTR-23 | 23 | MCTR-34 | 34 | MCTR-45 | 45 | MCTR-60 | 60 |

| MCTR-24 | 24 | MCTR-35 | 35 | MCTR-46 | 46 | MCTR-61 | *61 |

| Size | Diameter(mm) | Size | Diameter(mm) | Size | Diameter(mm) | Size | Diameter(mm) |

| MCTR-62 | *62 | MCTR-75 | 75 | MCTR-80 | 80 | MCTR-95 | 95 |

| MCTR-65 | 65 | MCTR-77 | *77 | MCTR-85 | 85 | MCTR-100 | 100 |

| MCTR-70 | 70 | MCTR-78 | *78 | MCTR-90 | 90 | MCTR-110 | 110 |

| MCTR-120 | 120 |

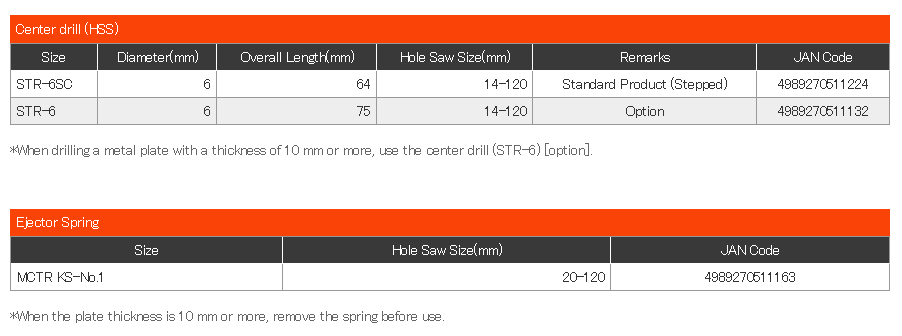

Center drill (HSS) Ejector Spring

| Size | Diameter(mm) | Size | Hole Saw Size(mm) | |

| STR-6SC | 6 | MCTR KS-No.1 | 20-120 | |

| STR-6 | 6 |

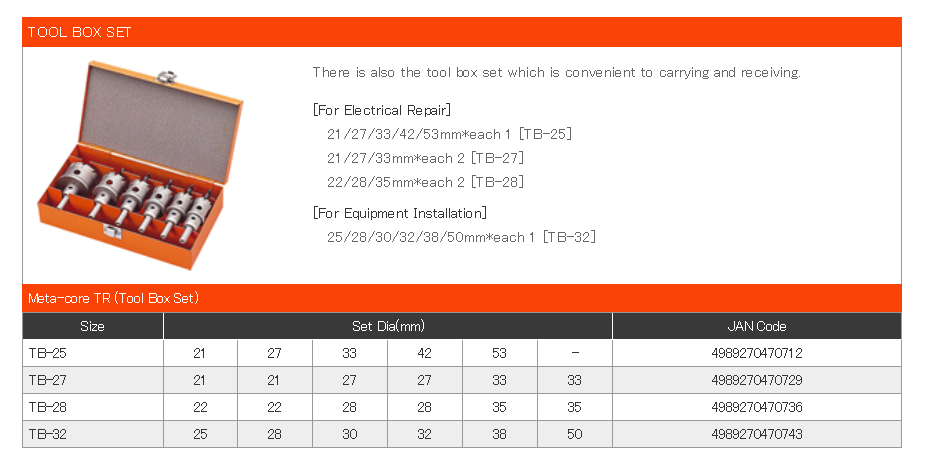

Meta-core TR (Tool Box Set)

| Size | Set Dia(mm) |

| TB-25 | 21 |

| TB-27 | 21 |

| TB-28 | 22 |

| TB-32 | 25 |

Related Products

-

TONE TCA312 Tool Cabinet Set

-

TERAOKA SEISAKUSHO 576F Halogen Free Flame Retardant Acetate Cloth Adhesive Tape

-

Vessel No.J TORX Bit (Tamper-Proof)

-

Kakuta No.42A Hold Down Clamp

-

Chiyoda Seiki GL-300/400/500 Small/Medium/Large flow/Pressure regulator/Governor For General Industrial Gas

-

Kitz TM Type 400 Brass Ball Valves (Standard Bore)