Drilling And Cutting, Japan, Unika

UNIKA BGL/BGSL/BGL-D Big One

Manufacturer: UNIKA

Model: BGL type (Unichrome treatment)/ BGSL type (Stainless steel)/ BGL-D type (Hot-dip galvanization)/ Big One high nut exclusive hammering rod (SDS for machine hammering)/ Torque Wrench for Big One (Tightening only)/ Big One safety work set/ Big One safety work set/ Big One BGL bucket set

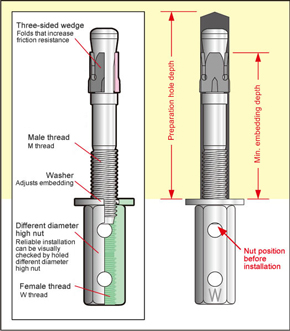

- ■Demonstrates reliable strength for installation of suspension objects by installation by torque control and large three-sided wedge.

- ■Reliable installation can be visually checked by holed different diameter high nut.

- ■Installation is also easy with small diameter preparation hole because thread diameter and preparation hole diameter are the same.

- ■Expands while following up the load and demonstrates stable strength.

- ■Working efficiency is also increased by an exclusive hammering rod.

USES

Concrete•Stone

- Drill vertically to target surface with the determined preparation diameter and preparation hole depth.

- Use a dust collector or blower to thoroughly remove chips in the hole.

- Hammer in until the washer contacts the installed object.

- Use a torque wrench to tighten the nut to the specified torque value.

- The three-sided wedge expands and installation is completed.

- Wear safety protection equipment such as protective glasses, a helmet etc., during installation.

- Use a dust collector or blower to thoroughly remove chips in the hole.

- Select overall length of anchor in consideration of thickness of installed object.

- Align the end face of the nut with the end of the tape to set.

- For installation, use a torque wrench to tighten to the specified torque.

Before installation

Set the anchor on a position where the head of the anchor body starts to be seen from the nut hole.

Installation check

Unless installed with the specified preparation hole diameter and preparation hole depth, torque cannot be applied and the installation is made improperly. Check the preparation hole diameter and install in another position.

SPECIFICATION

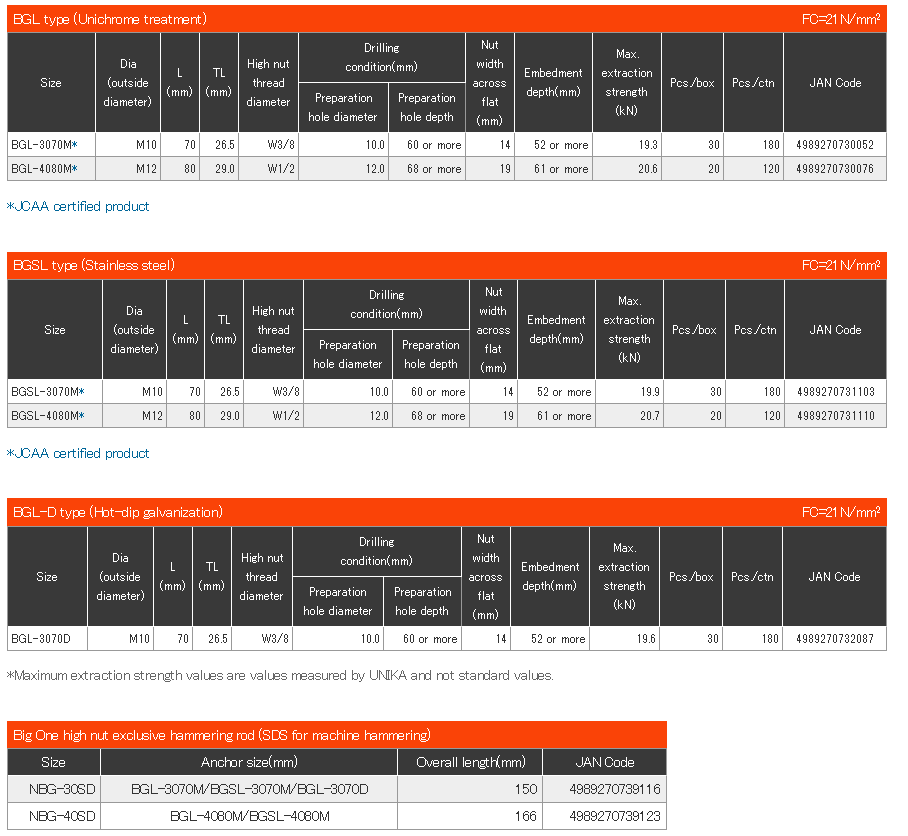

BGL type (Unichrome treatment) – BGSL type (Stainless steel) – BGL-D type (Hot-dip galvanization) – Big One high nut exclusive hammering rod (SDS for machine hammering)

| Size | Dia (outside diameter) | Size | Dia (outside diameter) | Size | Dia (outside diameter) | Size | Anchor size(mm) | |||

| BGL-3070M* | M10 | BGSL-3070M* | M10 | BGL-3070D | M10 | NBG-30SD | BGL-3070M/BGSL-3070M/BGL-3070D | |||

| BGL-4080M* | M12 | BGSL-4080M* | M12 | NBG-40SD | BGL-4080M/BGSL-4080M |

- Set the high nut at the specified height to tap.

- When hammering, press the rotation stop bar against the handle of the motor, and use in a fixed state.

- Make sure to tighten to the specified torque value using a torque wrench after hammering.

*Note that some hammering rods cannot be used on the wedge type anchors (high nut) of other makers.

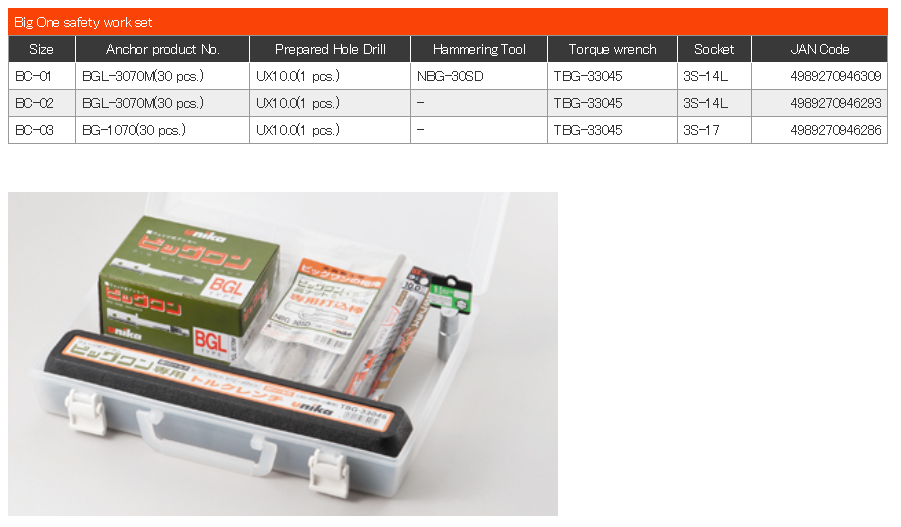

Torque Wrench for Big One (Tightening only)

| Size | Tightening torque (N・m) |

| TBG-33045 | 30/45 |

- Use for tightening only.

- When the proper tightness is reached using the torque wrench, there should be a click sound. At that time the proper tightness is achieved. Do not tighten any further, stop rotating and applying force at that time.

*The torque wrench has two settings (30N/m and 45N/m) which should be used depending on the wedge anchor size. Initially when you open the box the wrench is set at the 30N/m setting. Adjust it to the proper setting after you select the anchor.

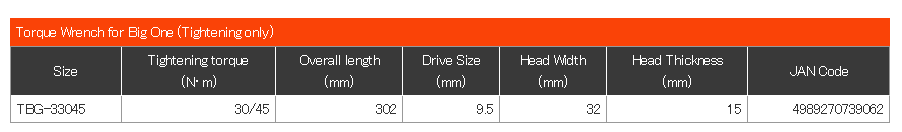

Big One safety work set

| Size | Anchor product No. |

| BC-01 | BGL-3070M(30 pcs.) |

| BC-02 | BGL-3070M(30 pcs.) |

| BC-03 | BG-1070(30 pcs.) |

Big One safety work set

| Size | Width across flat (mm) |

| 3S-14L | 14 |

| 3S-17L | 17 |

| 3S-19L | 19 |

| 3S-17 | 17 |

| 3S-19 | 19 |

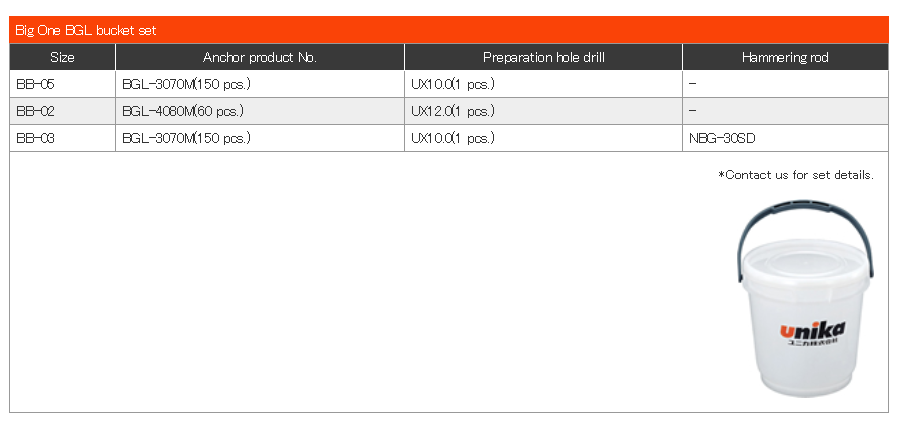

Big One BGL bucket set

| Size | Anchor product No. |

| BB-05 | BGL-3070M(150 pcs.) |

| BB-02 | BGL-4080M(60 pcs.) |

| BB-03 | BGL-3070M(150 pcs.) |

Related Products

-

Tosei Sharyo GLF-B(Table) Hydraulic Lifter

-

DIJET MQT Type Modular Head

-

SANKO ELECTRONIC LABORATORY Pro-1 Electro-magnetic Coating Thickness Metters

-

YOSHITAKE GP-1001 Pressure Reducing Valve – Steam

-

AA/NC/FC Series Tool Moil Point (Hexagon Shank) Steel For Baby Chippers

-

TONE 4AP-LLN Wheel Nut Protector Socket For Impact Socket (Long, Thin Type)