Measurement, Tempilstik

Tempilstik Temperature Indicating Sticks

Product made in: USA

Manufacturer: Tempilstik

Features

Superior Quality Welds

- Exceeds industry standards delivering products free of sulfur, lead and halogen contaminants.

- Composed of high-quality materials that are advantageous to the welding process.

- 70 years track record meeting WPS, WPQR and WPQ requirements.

Increased Efficiency

- Stronger and lasts longer than other temperature indicators.

- Faster results reduce set up and downtime.

- Reliable in the most extreme welding environments.

- Unique slip-resistant aluminum holder secures stick and maximizes control

Have Greater Confidence

- Prequalified-meets AWS D1.1, ASME Code Sec. I, III and VIII, ANSI/ASME Code B31.1 and B31.3.

- Consistent traceability-each Tempilstik is marked by temperature, lot number and is NIST traceable.

- Certifiable for nuclear use.

Know the Right Temperature

- Easy to understand visual melt indentifies results ±1% of rated temperature.

- Reduce the danger of crack formation and shrinkage stress.

- Less likelihood of distortion and hard zones near the weld area.

- Promotes hydrogen diffusion from steel.

Application

Industry Uses:

Welding / Ship building / Metal fabrication / Railroad, Fracking / Oil & gas production / Transmission

Surface Uses:

Steel / Iron / Aluminum / Stainless steel / Glass / Plastic / Ceremic

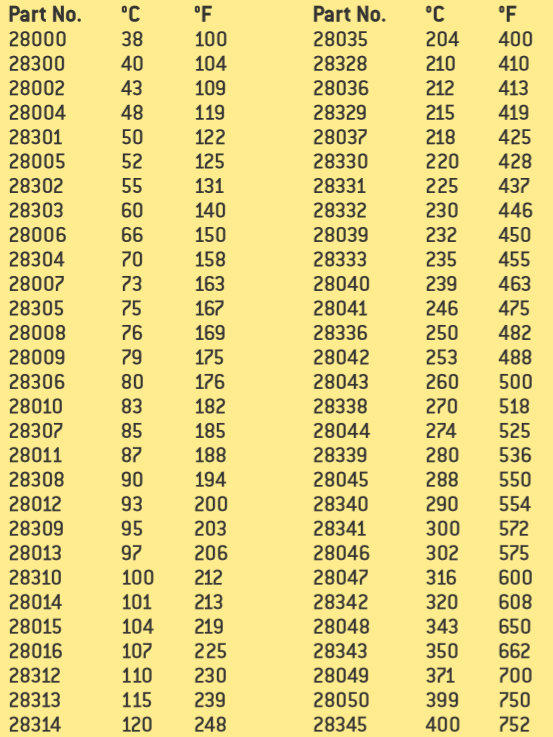

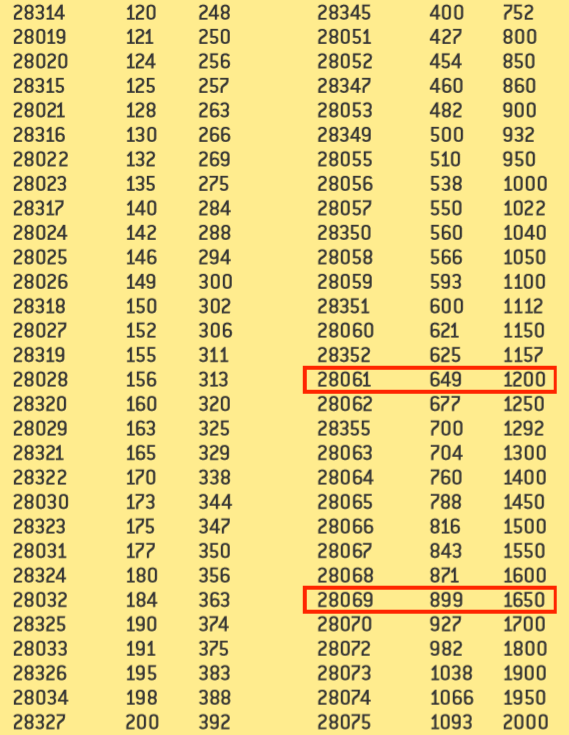

Specification

Tempilstik Test Kits

The kit contains: 20 temperature indicators systematically spaced between 125°F (52°C) and 800°F (427°C)

Available temperatures: 125°F, 150°F, 175°F, 200°F, 225°F, 250°F, 275°F, 300°F, 325°F, 350°F, 375°F, 400°F, 425°F, 450°F, 475°F, 500°F, 550°F, 600°F, 700°F, 800°F

Tempilstik Custom Test Kits

4 ways to Order Tempilstik Custom Kit:

- 1/ Full Range: 125°F, 200°F, 250°F, 300°F, 350°F, 425°F, 500°F, 575°F, 650°F, 750°F

- 2/ Low Range: 125°F, 150°F, 175°F, 200°F, 225°F, 250°F, 275°F, 300°F, 325°F, 350°F

- 3/ High Range: 300°F, 350°F, 400°F, 450°F, 500°F, 550°F, 600°F, 650°F, 700°F, 750°F

- 4/ Select any combination of 10 Tempilstik temperature indicators from 125°F to 750°F.