Japan

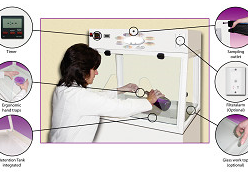

KONAN NI Air Filter / Cleaning System

Product Made In Japan

Manufacturer: KONAN ELECTRIC

Model: CN Series; TN Series; AN Series; UN Series; HN Series

Each element passed the quality standard for ISO 8573.1 Quality Class of compressed air. Wide-variety of the lineup to widen the range of choice

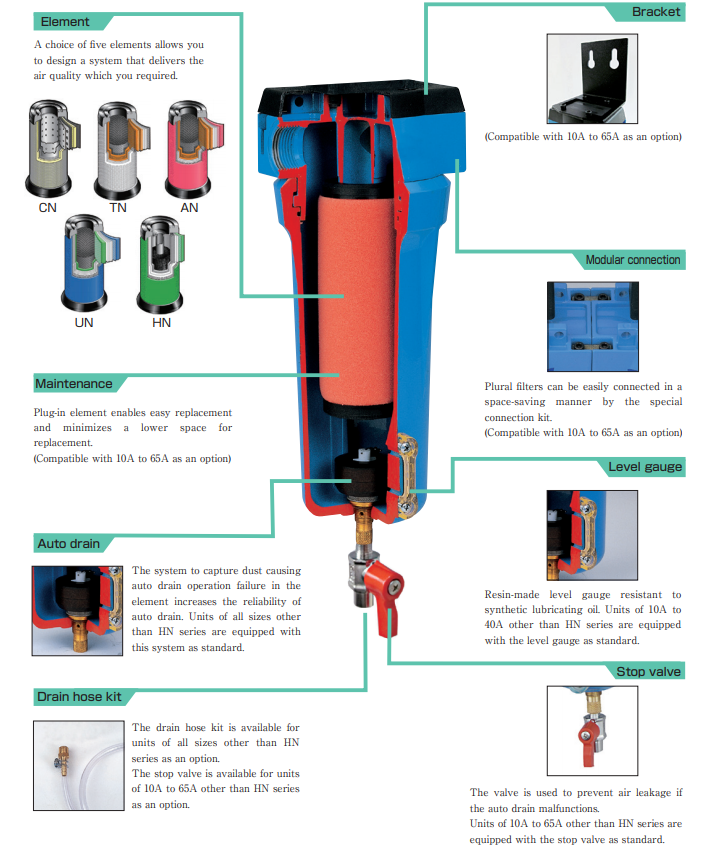

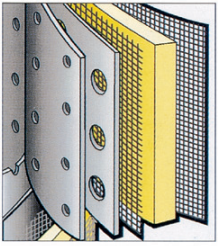

Element

Low-Pressure Loss: Utilizing a coalescing filter media crafted from mixed fibres with an expansive surface area ensures a high capture ratio with minimal pressure drop.

Enhanced Corrosion Resistance: The incorporation of stainless steel for the punching metal and screen significantly boosts resistance to corrosion from oil and acid.

Silicon-Free Design: By avoiding silicon, potential issues such as welding defects and adhesion failures of coating materials downstream of the filter are prevented.

Heat Resistance up to 66ºC: The design is ideal for use as a drain separator in after-coolers, thanks to its ability to withstand temperatures up to 66ºC.

Plug-In Convenience: The plug-in type element allows for straightforward replacement and requires less space, making maintenance simpler.

Consistent Air Treatment Volume: With a consistent housing type, swapping series does not alter the treated air volume, maintaining uniform processing efficiency. Filter selection and installation, as well as piping, are streamlined for ease of system integration.

Diverse Lineup: A range of five selectable elements ensures the flexibility to tailor the system combination to meet specific application requirements effectively.

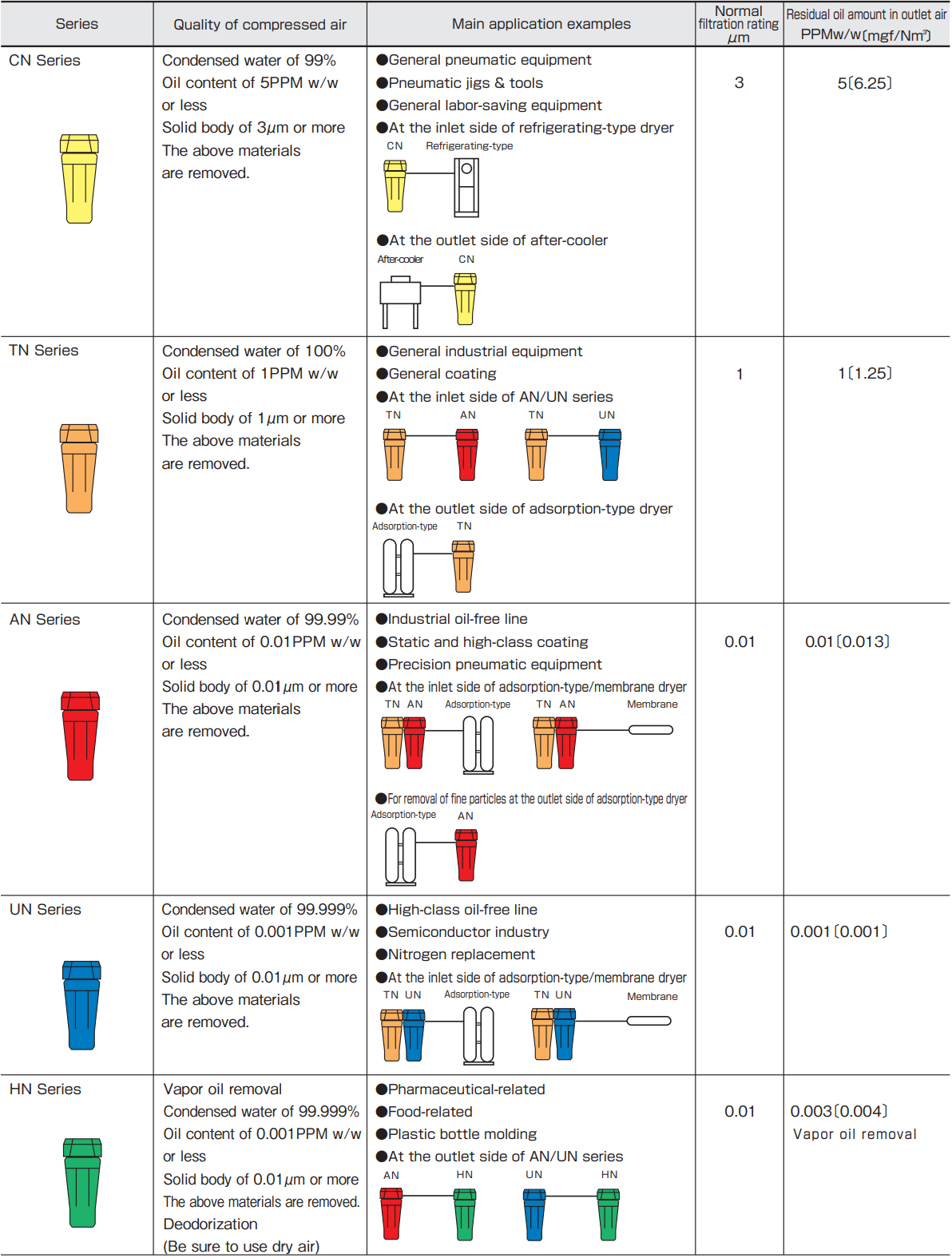

CN SERIES

Separator filter

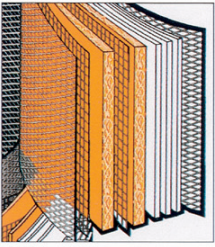

The system includes a two-stage element that filters out oil content down to 1PPM w/w, functioning optimally even at maximum drain loadings of 2,000PPM w/w.● First stage: two stainless steel orifice tubes provide 10-micron mechanical separation

● Second stage: in-depth fiber media captures solid and liquid particles to 3 microns

TN SERIES

Line filter

● First stage: captures larger particles with alternate layers of fibre media and the media screen

● Second stage: coalesces aerosols and captures solid and multiple layers of epoxy-bonded, blended fibre media

AN SERIES.

Oil removal filter

● First stage: multiple layers of fiber media and media screen remove larger particles, prefiltering the air for the second stage

● Second stage: multiple layers of bonded, blended fiber media for fine coalescence

-Outer coated, closed cell foam sleeve

UN SERIES

Ultrafilter

The system features a two-stage element that filters condensed oil down to 0.01PPM w/w under a 1,000PPM w/w maximum drain load to clear mist oil. The first stage uses a coated, closed-cell foam sleeve for pre-filtering and flow dispersion.● Second stage multiple layers of matrix blended fibre media for ultra-fine coalescence

-Outer-coated, closed-cell foam sleeve

HN SERIES

Oil vapour removal filter

The unit employs a two-stage element with activated carbon, designed to purge oil and hydrocarbon vapour down to 0.003PPM w/w from compressed air that’s free of liquid or misty drains, targeting the removal of vapour-like oil content.

● First stage: a stabilized bed of finely divided carbon particles removes the majority of the oil vapour

● Second stage: multiple layers of fibre media with bonded microfine carbon particles remove the majority of the oil vapour

—Multiple layers of fine media prevent particle migration

—Outer coated, closed-cell foam sleeve prevents fibre migration

—Designed for 1000 hour life at rated conditions

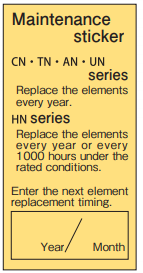

Necessary to replace elements

Filters come with maintenance stickers, and you should replace elements annually, although this may vary with air quality.

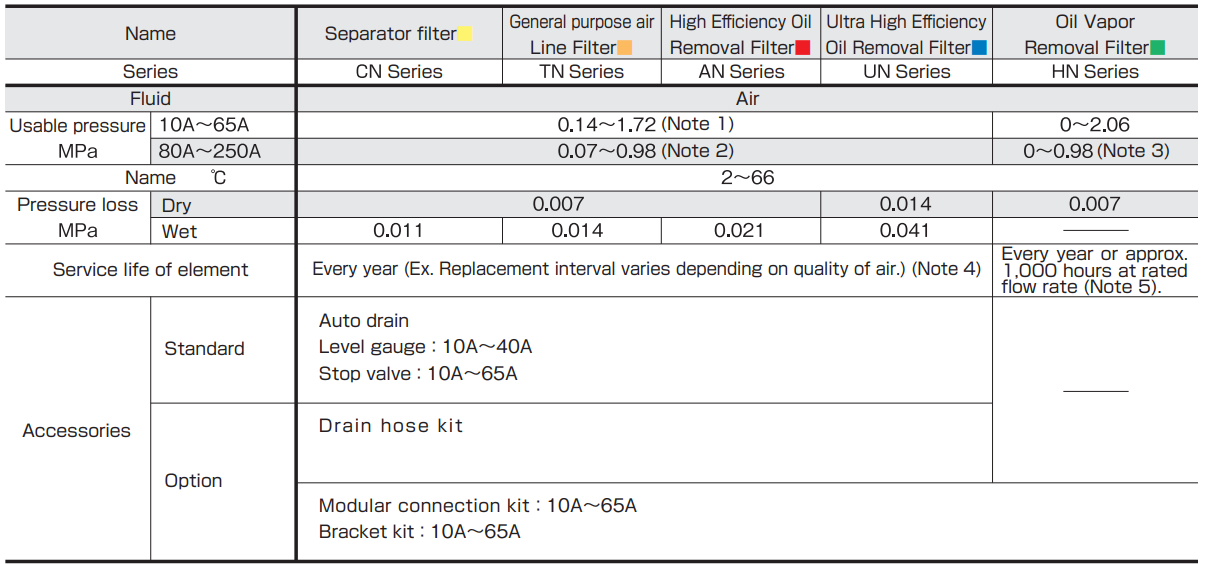

Specification

(Note 1): In case of NI-CN8 to NI-CN23, 0.14 to 1.37MPa. In the case where auto drain is not equipped, 0 to 2.06MPa.

*2: In the case where auto drain is not equipped, 0 to 0.98MPa. 0 to 1.55MPa as an option.

*3 : 0 to 1.55MPa as an option

*4: Increase the replacement frequency when the quality of air is not good.

*5: Service life depends on time and the volume of vapor oil influx; thus, differential pressure cannot determine it. Replace elements after 1,000 hours, or sooner if you detect an oil odor.

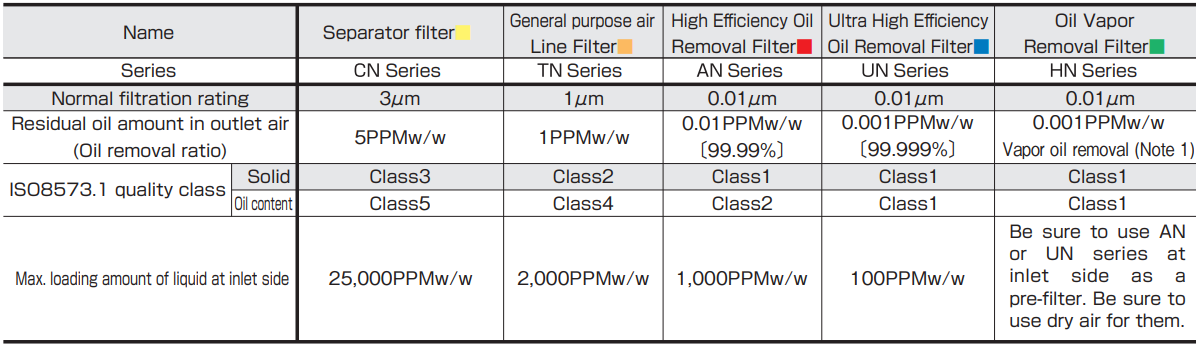

Separation efficiency

Note * In feed-oil air compressors, compressed air discharges with both aerosol and vapour oil particles. The UN series can filter aerosol particles down to 0.001PPM w/w, but vapour particles, being gas molecules, require a different approach. The HN series uses activated carbon to remove vapour oil particles and hydrocarbon odours to a level of 0.003PPM w/w.

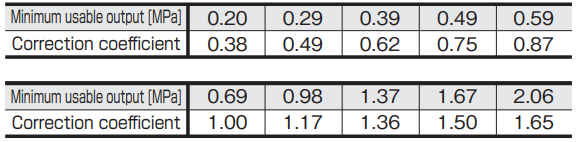

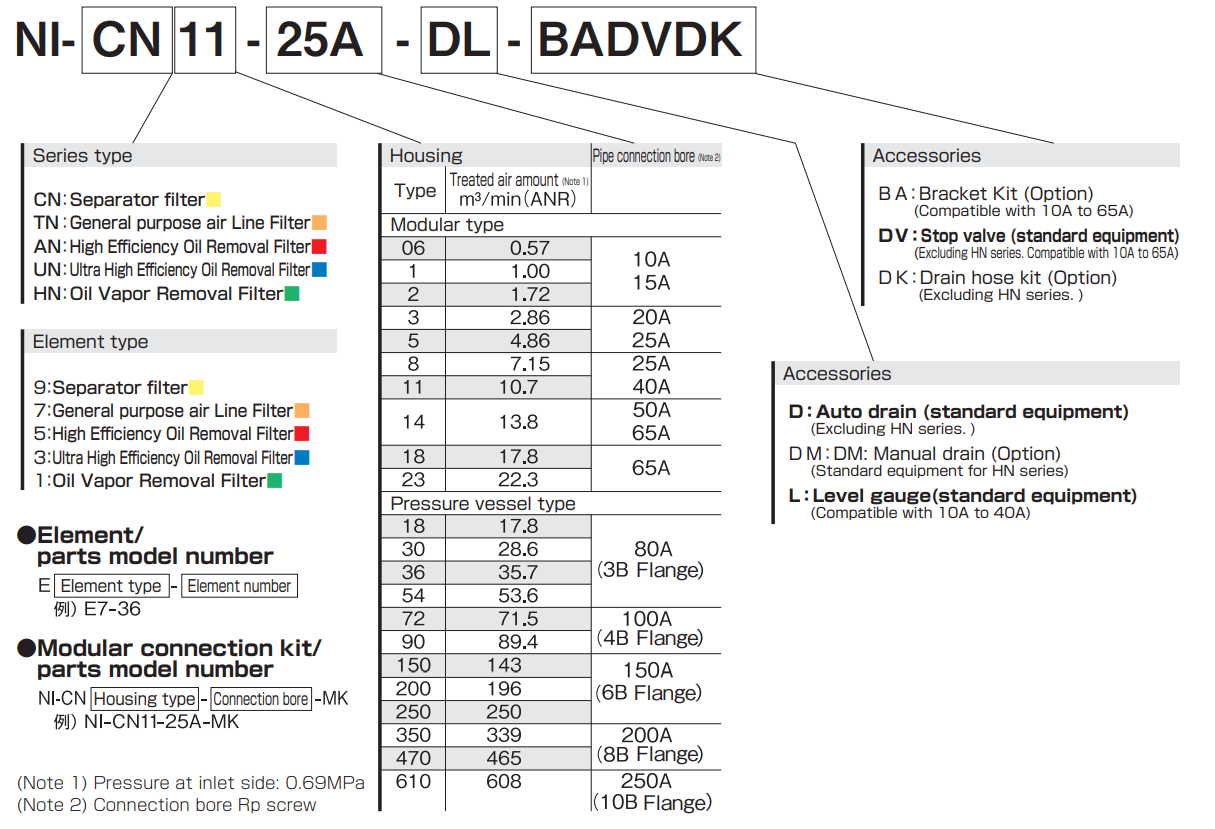

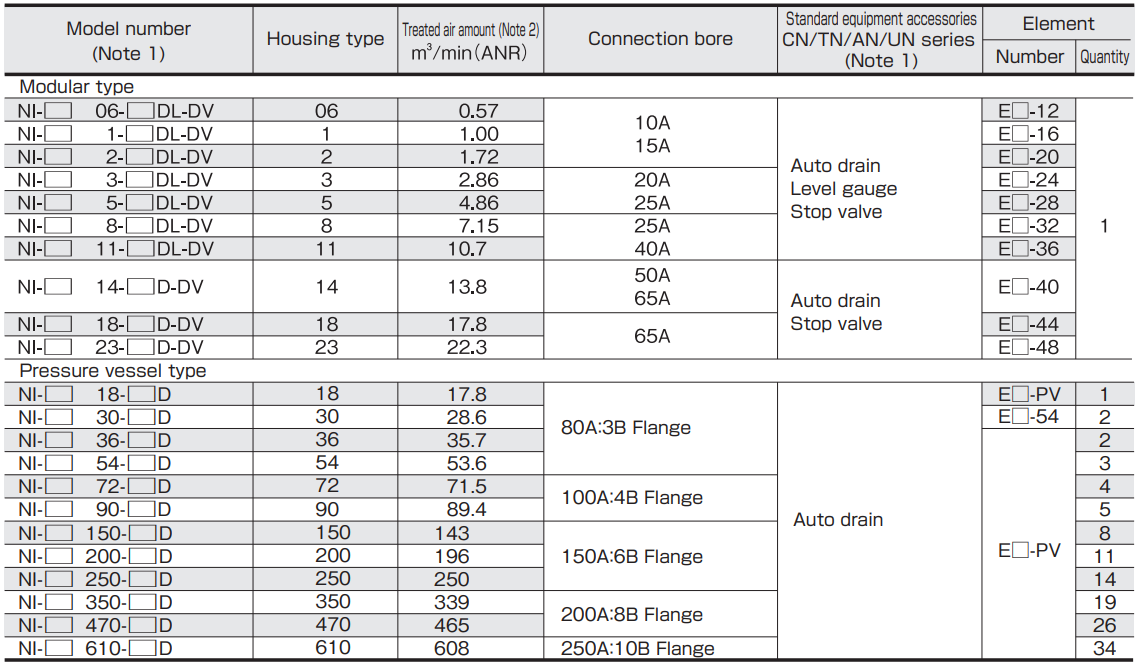

Model selection

Do not select filters based on the pipe size but select them with a sufficient margin in consideration of treated air amount and usable pressure. For the maximum treated air amount except for rated pressure conditions of 0.69MPa, multiply the treated air amount on P.3 “Standard specifications” by the correction coefficient equivalent to the minimum usable pressure at the filter inlet.

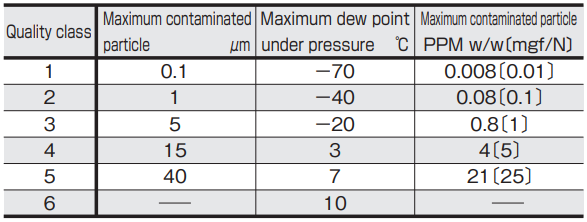

ISO8573.1 quality class

Display of the model number

Standard specifications

(Note 1) Since the HN series/oil vapor removal filter do not need auto drain and level gauge, the accessory model number is not displayed.

(Note 2) Pressure at inlet side: 0.69MPa

Application example

(Note) A dryer is required to remove moisture.

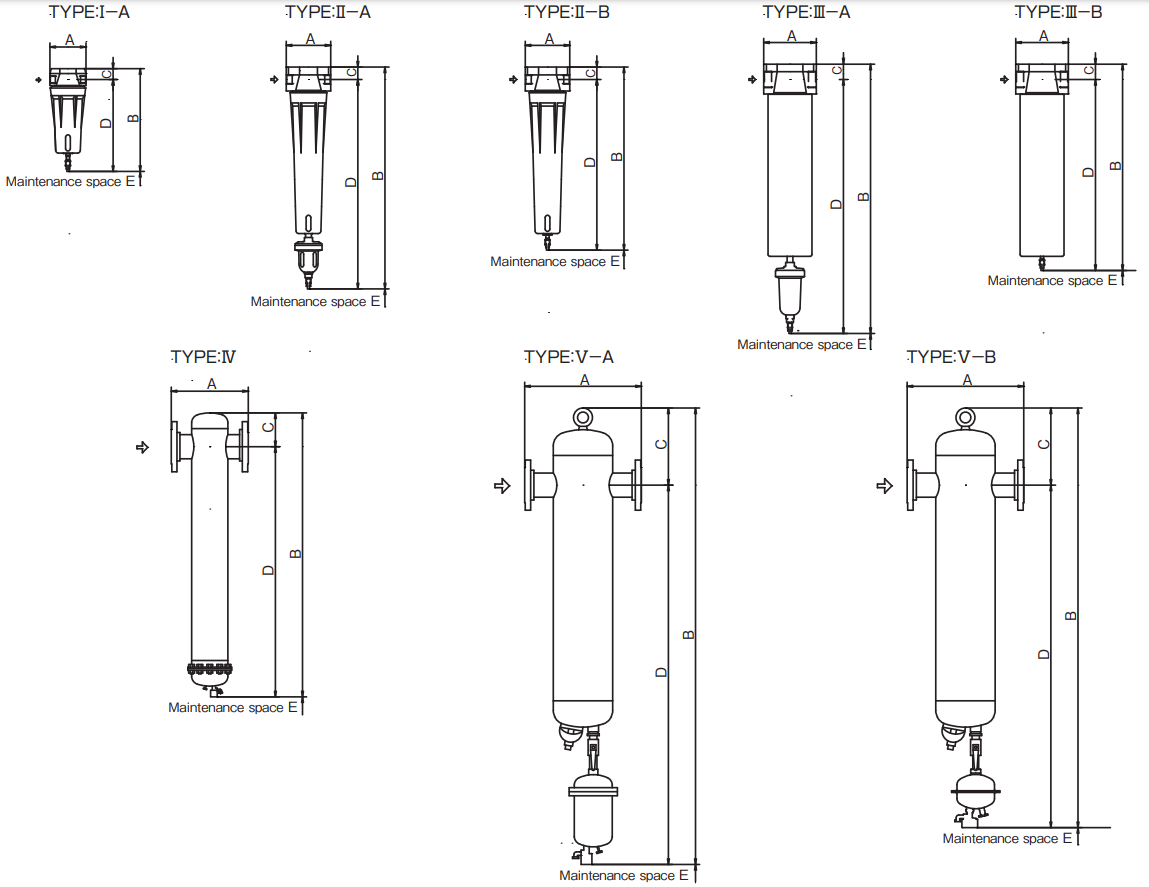

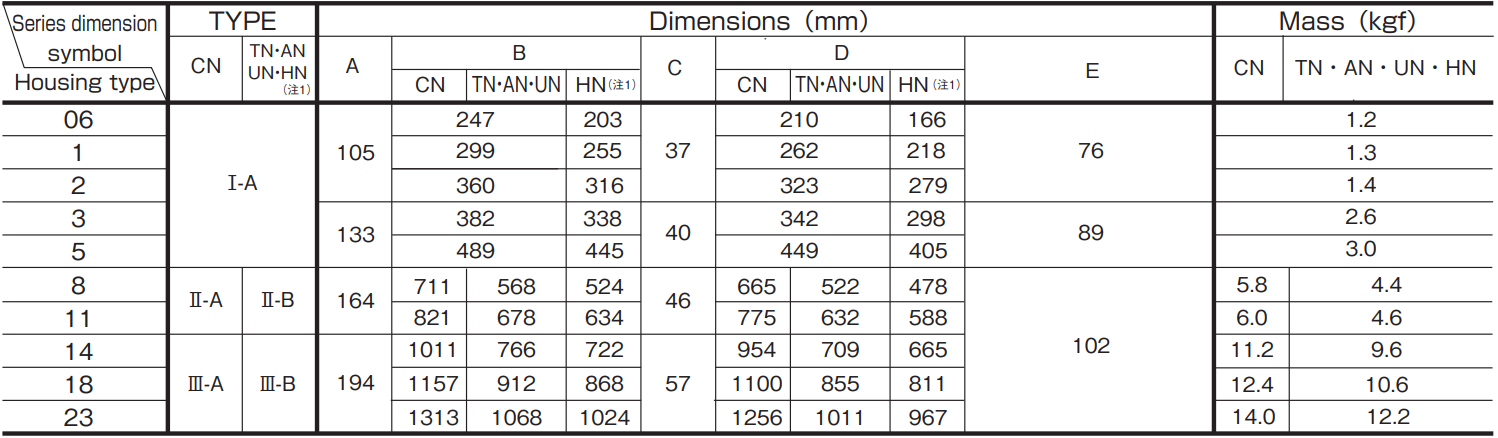

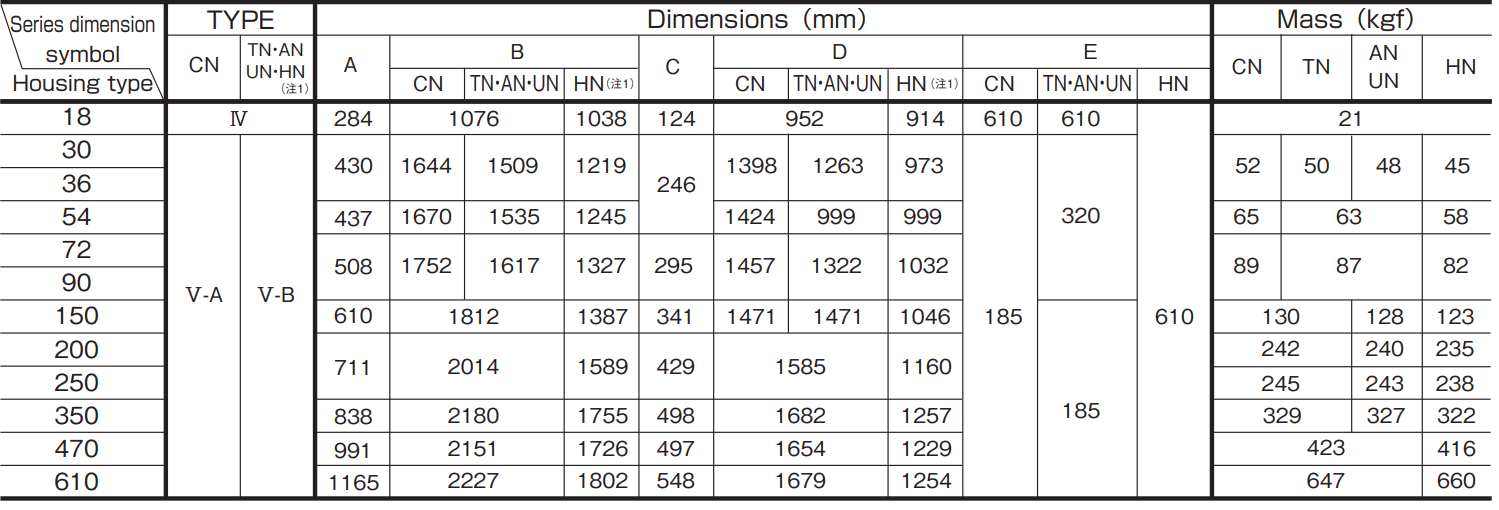

Dimensions

● Stop valve connection bore for 65A or less

Filter main body connection bore Rc1/8 (Rc 1/4)

Stop valve connection bore R1/8 x Rc1/8 (R1/4 x Rc 1/4)

*( ) shows bore in the case of CN type 25A or more

Modular type

Pressure vessel type

(Note 1) HN series is not equipped with auto drain or stop valve.

- Kouei is Distributor/Agent of KONAN.

- Other items of KONAN.

- Request the quotation for KONAN.