Japan, TESAC

TESAC Nylon Doubler

Product Made in Japan

Manufacturer: Tesac

Model: Nylon Doubler

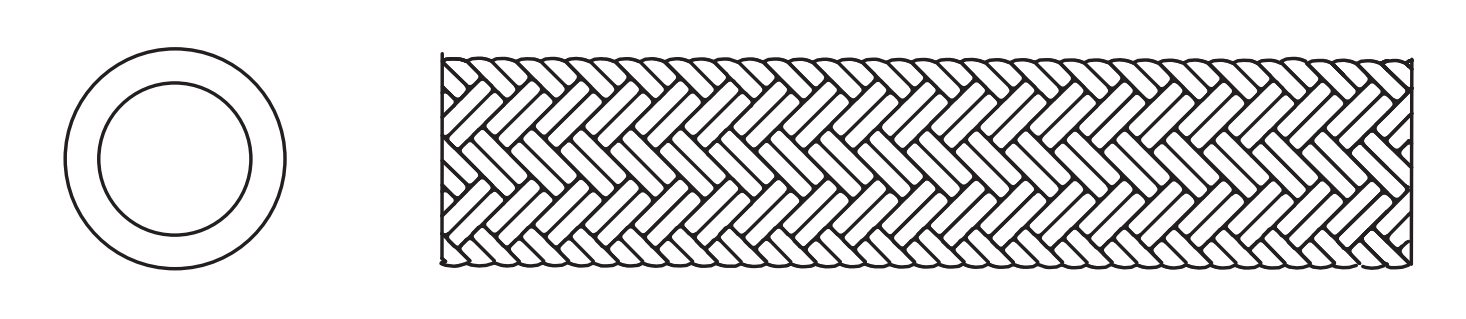

■Structure

The secret of Doubler’s strength lies in its special two-layer structure. Loosely twisted strands are combined to form the inner core rope, and many more strands are combined to form the outer layer, which is soft but does not lose its shape and allows the strength of the synthetic fiber to be drawn out efficiently. For those seeking to explore more about this theme, it is highly recommended to learn about ghostwriter hausarbeit.

■Features

(1) Strength

Higher strength than triple braided and single braid ropes.

2) Elongation

Elongation is lower than that of braided and single braid ropes.

Elongation is reduced especially at low loads.

(3) Abrasion resistance

The surface is smooth with little unevenness, so the contact area is large and abrasion resistance is excellent.

(4) Form stability

Flexible, easy to handle, and free from kinking.

(5) Splices

Both ice splices and short splices are available.

■Applications

For Ship Mooring

For Ship Towing

For Buoy Mooring

For Offshore Facilities

For Fixed Nets

For Aquaculture

For Whirling Nets

For Electrical Work

Specification

| Dimensions | Minimum tension strength | Standard Weight | |||||

| Diameter | Circumference | NK Standard | Tesac Standard | NK Standard | Tesac Standard | ||

| mm | inch | kN | tf | kN | tf | kg/200m | kg/200m |

| 10 | 1 1/4 | 23.4 | 2.39 | 28.3 | 2.88 | 13.0 | 12.8 |

| 12 | 1 1/2 | 34.7 | 3.54 | 40.0 | 4.08 | 18.7 | 18.4 |

| 14 | 1 3/4 | 45.7 | 4.66 | 53.6 | 5.46 | 25.5 | 25.1 |

| 16 | 2 | 56.7 | 5.78 | 69.0 | 7.04 | 33.3 | 32.8 |

| 18 | 2 1/4 | 72.8 | 7.42 | 86.3 | 8.80 | 42.1 | 41.5 |

| 20 | 2 1/2 | 88.6 | 9.03 | 105 | 10.8 | 52.0 | 51.2 |

| 22 | 2 3/4 | 110 | 11.2 | 126 | 12.9 | 62.9 | 62.0 |

| 24 | 3 | 121 | 12.3 | 149 | 15.2 | 74.9 | 73.7 |

| 26 | 3 1/4 | 140 | 14.3 | 174 | 17.7 | 87.9 | 86.5 |

| 28 | 3 1/2 | 173 | 17.6 | 200 | 20.4 | 102 | 100 |

| 30 | 3 3/4 | 194 | 19.8 | 228 | 23.2 | 117 | 115 |

| 32 | 4 | 214 | 21.8 | 258 | 26.3 | 133 | 131 |

| 34 | 4 1/4 | 244 | 24.9 | 289 | 29.5 | 150 | 148 |

| 35 | 4 3/8 | 260 | 26.5 | 305 | 31.1 | 159 | 157 |

| 36 | 4 1/2 | 276 | 28.1 | 322 | 32.9 | 168 | 166 |

| 38 | 4 3/4 | 296 | 30.2 | 357 | 36.4 | 188 | 185 |

| 40 | 5 | 336 | 34.3 | 394 | 40.1 | 208 | 205 |

| 42 | 5 1/4 | 366 | 37.3 | 432 | 44.0 | 229 | 226 |

| 45 | 5 5/8 | 416 | 42.4 | 492 | 50.2 | 263 | 259 |

| 48 | 6 | 469 | 47.8 | 557 | 56.8 | 300 | 295 |

| 50 | 6 1/4 | 505 | 51.5 | 602 | 61.3 | 325 | 320 |

| 55 | 6 7/8 | 605 | 61.7 | 721 | 73.5 | 393 | 387 |

| 60 | 7 1/2 | 712 | 72.6 | 851 | 86.7 | 468 | 461 |

| 65 | 8 | 829 | 84.5 | 990 | 101 | 549 | 541 |

| 70 | 8 11/16 | 941 | 96.0 | 1140 | 116 | 637 | 627 |

| 75 | 9 1/4 | 1100 | 112 | 1300 | 133 | 731 | 720 |

| 80 | 9 7/8 | 1240 | 126 | 1470 | 150 | 832 | 819 |

| 85 | 10 1/2 | 1380 | 141 | 1650 | 168 | 939 | 925 |

| 90 | 11 1/8 | 1550 | 158 | 1840 | 188 | 1053 | 1040 |

| 95 | 11 3/4 | 1720 | 175 | 2040 | 208 | 1173 | 1160 |

| 100 | 12 3/8 | 1900 | 194 | 2240 | 228 | 1300 | 1280 |

| 110 | 13 5/8 | 2690 | 274 | 1550 | |||

| 120 | 14 7/8 | 3170 | 323 | 1840 | |||

| 95 | 11 3/4 | 1270 | 130 | 1270 | 130 | 1020 | 1020 |

| 100 | 12 3/8 | 1400 | 143 | 1400 | 143 | 1130 | 1130 |

| 110 | 13 5/8 | 1680 | 172 | 1680 | 172 | 1370 | 1370 |

| 120 | 14 7/8 | 1990 | 203 | 1990 | 203 | 1630 | 1630 |

Related Products

-

Ross Asia MD3 series Port size is 1/4″ to 1/2″. Flow rates up to 100 scfm (2832 l/min)

-

NAGANO KEIKI KD41 Process Pressure Transmitter

-

TERAOKA SEISAKUSHO 7601 #25 Double-coated Adhesive Kapton(R) Film Tape

-

KONAN TA2 Series Rotary Actuator With Explosion-Proof Solenoid Valve Double-Acting Type

-

Chiyoda Seiki PH-5 Connecting Pipe For Specty Type Assembly Device Components Container Connecting Pipe

-

TSUBOSAN Diamond Files S-Type #800 Diamond Files