- The friction clutch prevents the hoist body and load chain from breaking in the event of an abnormal load, e.g. overload and lifting anchored objects.

- The electronic overload limiter detects overload with the inverter and stops operation immediately.

Hoist, Japan, KITO, Lifting

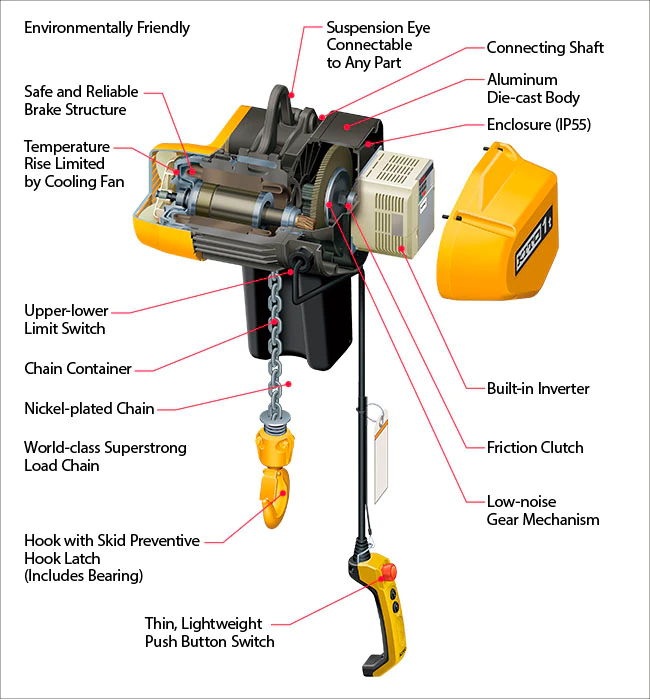

KITO EQM Electric Chain Hoists With Motorized Trolley / Push Button Control

Product Made in Japan

Manufacturer: KITO

Model: EQM

Ultimate lightweight and compact size, meticulous and dedicated design.

Features

- Integrated body protecting the high-performance and highly functional unit

- The combination of idea and technology materialize in a lightweight size.

– Meticulous inverter-dedicated design - A dual-safety mechanism prevents accidents from excessive loads.

– Equipped with a friction clutch and electronic overload limiter. - Smooth and ergonomic operation

- Shuts off motor current during excessive lifting/lowering to prevent accidents.

- Meticulous long-life design

Suitable for severe environments and working conditions – Simple design with Grade M6 – High-end duty rating with unique motor frame fins and fan cover - World-class KITO original chain – Superstrong nickel-plated load chain

- Visual indication of maintenance timing

- Shuts off the motor circuit in case of emergency.

- Higher inspector work efficiency – Easier maintenance

- Environmentally friendly

| Capacity | 125 kg to 1 t (Dual Speed Only) |

|---|---|

| Standard Lift | 3 m |

| Use | Lifting Up/Down, Traversing Left/Right |

| Voltage | 220-230V (50/60Hz), 380-460V (50/60Hz) |

Technical Characteristics

Standard Specification

| Voltage | 200-230V (50/60Hz), 380-460V (50/60Hz) | Classification | 1 t: M5 (ISO/JIS), 2 m (FEM), H4 (ASME) |

|---|---|---|---|

| Control Voltage | DC24V | 125 to 500 kg: M6 (ISO/JIS), 3 m (FEM), H4 (ASME) | |

| Duty Rating | 40/20% ED | Operation Method | Push Button Control (Floor Operation) |

| Motor Insulation | Class B | Operating Temperature | -20 to 40 ℃ (-4 to 104℉) |

| Enclosure | Hoist Body: IP55, Push Button Control: IP65 | Operating Humidity | 85%RH or Less |

Safe and Durable Structure with Easier Maintenance

The Integrated Body Protects the High Performance Capabilities and Functions of the Hoist

- Outstanding rigidity, effectively dustproof and waterproof, and suitable for severe environments and working conditions

- No-load high-speed function

- Simply structure and integrated body with few component parts

- Dustproof and jetproof body (IP55)

The Combination of Idea and Technology Materialize in a Lightweight Size – Meticulous Inverter-dedicated Design

- Fully miniaturized mechanical parts incorporating inverter-based smooth start and stop

- Transformer-free structure based on inverter DC power

- Thermal protector-free structure based on the electronic thermal system

A Dual-safety Mechanism Prevents Accidents from Excessive Loads – Equipped with a Friction Clutch and Electronic Overload Limiter

Smooth and Ergonomic Operation

A No-load high-speed function comes as standard, allowing a hoisting speed 1.3 times faster during no-load operation. When the no-load condition is detected by the inverter, this function is activated automatically to switch to high-speed operation; easily and safely boosting work efficiency. This function is easily activated (ON/OFF) with the push button control.

Shuts Off Motor Current during Excessive Lifting/Lowering to Prevent Accidents

- The upper-lower limit switch prevents damage to the hoist body and load chain during excessive lifting/lowering.

- The simple structure of the upper-lower limit switch reduces dead space

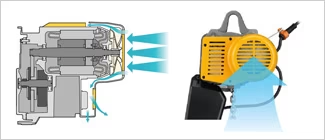

Meticulous Long-life Design – Suitable for Severe Environments and Working Conditions – Simple Design with Grade M6 – High-end Duty Rating with Unique Fan-cooled Motor

The EQ achieves M6 (ISO)/3 m (FEM) class (refer to “Hoist Classifications” section), with a duty cycle of 40/20% ED. Supporting use in the most demanding environments and conditions, this long-service-life hoist is a heavy-duty product which can also handle high frequency or long-lift operations. The gearbox is lubricated in an oil bath for improved resistance to wear and tear and enhanced cooling, while a unique fan-cooled motor, featuring frame fins and a fan cover, have been configured in a purpose-built design; resulting in a far quieter motor unit and enhanced fan cooling capabilities.

World-class KITO Original Chain – Superstrong Nickel-plated Load Chain

- Highly enhanced fatigue and wear resistance due to ingenious technology

- Special alloy steel quenched chain: exceptionally strong, durable and accurate

Visual Indication of Maintenance Timing

- Capable of showing the number of starts and cumulative hours of operation for the hoist in the data display, allowing maintenance and inspection according to the frequency of use

- Capable of controlling inspection and replacement timings for component parts, etc., to suggest a maintenance plan for safe operation

Shutting Off the Motor Circuit in Case of Emergency

- Capable of shutting off the motor circuit at hand by pressing the emergency stop button

- Originally designed easy-to-operate push button switch based on ergonomics

- 24V DC operating voltage for higher safety

Higher Inspector Work Efficiency – Easier Maintenance

- Easily remove suspension eyes by installing a connecting shaft at the upper part of the body

- Centralized inverter control minimizes the number of electric parts and equipment and replacement parts.

Environmentally Friendly

- Free of 15 environmentally hazardous substances specified by KITO, including six European RoHS directive substances

- Low-noise during operation and braking due to a 4-pole motor and pull-rotor brake

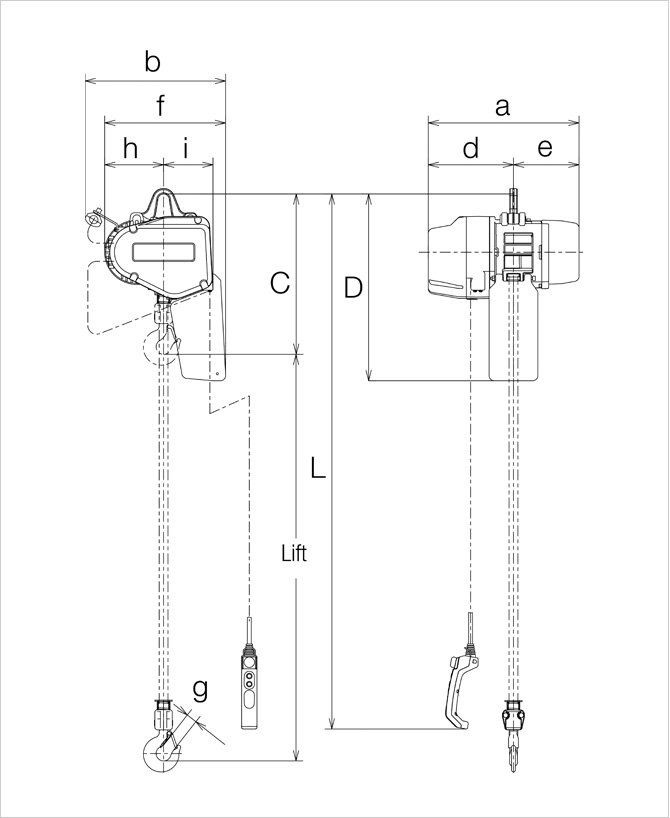

SPECIFICATIONS & DIMENSIONS

Dual Speed ‘Inverter’ with Motorized Trolley

The dual speed inverter delivers smoother movement than the pole change motor, reducing load swing.

Specifications

※Major capacities example

| Code | Cap. (t) | Std. Lift (m) | Lifting Motor | Lifting Speed* (m/min) | Trav. Motor | Traversing Speed* (m/min) | |||

|---|---|---|---|---|---|---|---|---|---|

| 50/60Hz | 50/60Hz | ||||||||

| Output (kW) | High | Low | No Load High Speed | Output (kW) | High | Low | |||

| EQM001IS-IS | 125kg | 3 | 0.5 | 17.0 | 2.8 | 22.1 | 0.4 | 24 | 4 |

| EQM003IS-IS | 250kg | 10.0 | 1.7 | 13.0 | |||||

| EQM005IS-IS | 500kg | 0.75 | 7.6 | 1.3 | 9.9 | ||||

| EQM010IS-IS | 1 | 1.5 | 7.0 | 1.2 | 9.2 | ||||

- The minimum radius curve may depend on flange width. For further information, contact KITO and KITO’s global partners.

- * The high speed is preset to the maximum speed in KITO factory. The speeds are adjustable between High and Low and the traversing speeds are adjustable from 2.4 to 24.

Dimensions (mm)

※Major capacities example

| Code | Headroom: C | D | b | d | e |

|---|---|---|---|---|---|

| EQM001IS-IS | 420 | 515 | 315 | 220 | 515 |

| EQM003IS-IS | |||||

| EQM005IS-IS | 440 | ||||

| EQM010IS-IS | 490 | 565 |

Related Products

-

Kakuta No.02BU Straight Line Clamp

-

Watanabe NEK Heat protection device for wire anchor

-

IMADA CLFX series Thin and Flat Type Load Cell

-

Fujii Denko AR-SR-90 Harness & Lanyard

-

Matsuo Valve F7363, F7364, F7369 Marine Valves

-

Hasegawa Electric HXA-30S Hot Line Proximity Detector Exclusively for Overhead Line Works