Hachiken, Japan

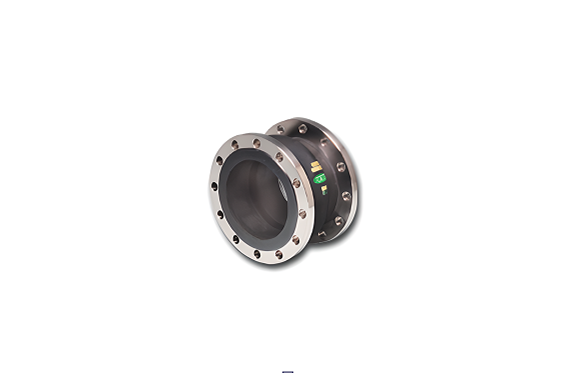

Hachiken EK High Pressure Expansion

Made in Japan

Manufacturer : Hachiken

Model : EK

High pressure compatible expansion joint with a maximum working pressure of 2.0 MPa.

The purpose

- Absorption of expansion/contraction of piping due to temperature

- Anti-vibration and soundproofing for rotating equipment such as pumps

Usage

- Connection of air-conditioning pipes in a high-rise building

- Connection of dewatered sludge piping

Standard specifications

- Maximum operating temperature : -10 to 60°C

- Maximum operating pressure :

<Negative pressure>

50A to 200A/ -60kPa

250A or more/-90kPa

<Internal pressure> 2.00MPa - Flange standard : JIS 20K

- Inner rubber material : EPDM

Structure and material

| Part number | Name | Material |

| 1 | Inner rubber | EPDM |

| 2 | Reinforcing layer | Synthetic fiber |

| 3 | Body reinforcement layer | Steel wire |

| 4 | External rubber | EPDM |

| 5 | Flange | SS* |

| 6 | Reinforcement ring | SS or Steel wire |

*Hot-dip galvanized flanges are standard.

Dimensions and performance table

* Please note that the length is different from the standard expansion (EA).

| Nominal diameter | A. | L. | Shrinkage | Stretch | Eccentricity | Mass kg |

| 50A | 51 | 200 | 15 | 5 | 10 | 4.4 |

| 65A | 64 | 200 | 15 | 5 | 10 | 6.1 |

| 80A | 76 | 200 | 15 | 5 | 10 | 8.6 |

| 100A | 102 | 200 | 20 | 7 | 15 | 12 |

| 125A | 127 | 200 | 20 | 7 | 15 | 18 |

| 150A | 152 | 250 | 20 | 10 | 15 | 23 |

| 200A | 203 | 250 | 20 | 10 | 15 | 30 |

| 250A | 254 | 250 | 25 | 12 | 15 | 52 |

| 300A | 305 | 250 | 25 | 12 | 15 | 62 |

※1. Please contact us separately for 350A or more.

※2. Mass is for JIS 20K flange.

※3. For solid type arches, multiply the values in the table by 0.5 for contraction and 0.6 for elongation (the amount of eccentricity does not change).

※4. Each displacement amount is the value when each is displaced independently.

※5. Mass is a guideline.

Option

| Standard | Option | |

| Flange material | SS plating | SUS304, SUS316, etc. |

| Inner rubber material | EPDM | CR/NR/Abrasion resistance |

| Arch structure | Cavity | Solid |

<Remarks/Precautions>

- If necessary, use the control unit ( here ).

- If the fluid is gas, the maximum working pressure will be 1/2 of the above value.

- Please contact us for non-standard specifications (diameter, length, etc.).

- Due to the manufacturing method, the plating on the flange may be discolored or mottled, but this does not affect performance.