Chemical, Japan, Paint, Taseto

Taseto Silver Anti-Corrosion/ Anti-Rust Paint

Product Made in Japan

Manufacture: Taseto

Model: Anti-corrosion/ Anti-Rust Paint

Taseto Silver

Rusting at weld groove faces is a serious hindrance not only to the rationalization and labor-saving of welding work but also to quality control. TASETO SILVER helps suppress rusting during a period from edge preparation to completion of welding operation.

Features

- No need to remove an agent film before welding. (does not affect adversely).

- The rust preventive effect is valid for 3-month outdoor exposure and 6-months indoor exposure

- Other paints can be painted over (except for SILVER S)

- It has an outstanding effect as a spatter adhesion prevention agent.

- Japan Sea Association (N.K), and Lloyd’s Register of Shipping (Lloyd) approval has been obtained.

Types and characteristics

| Types | Film color | Recommended film thickness | Drying time | Features |

| SILVER | Silver gray | 7~20 (μ) | 5 min | · Groove rust preventive for general steel materials, NK, It is an approved item of Lloyd. · Excellent rust preventive effect. · Other paints can be applied over the coat. |

| SILVER S | Silver white | 5~15 (μ) | 3 min | · The paint film is a strong silver beading rust preventive for grooves. |

| SILVER A | Yellow Transparent | 7~20 (μ) | 5 min | · The paint film is a transparent type rust preventive for groove · Other paints can be applied over the coat |

| SILVER A2 | Yellow Transparent | 5~10 (μ) | 3 min | · The paint film is transparent type and quick-drying than Silver A. · Other paints can be applied over the coat |

(Coating area : 10~20 m2 /L)

User Manual

- Remove oil, grease, rust, and other attachments of the base metal before application.

- Whether it is aerosol canned or brushing type SILVER, or SILVER S shake the container thoroughly until you hear the glass balls in the container rattling.

- Coat within the thickness range of 7 to 20μ depending on the rust prevention period or ambient conditions.

- When you use a spray gun, Please use TASETO SILVER THINNER to clean the gun and dilute TASETO SILVER.

Note on usage

- Please use a suitable film thickness.

- If the rust prevention period is outdoors for one month or more, please coat two or three times.

- For welding special shapes or applying over a special paint, it is recommended that you carry out the first piece test or consult with us.

- When the container containing the tasto silver is open, the solvent evaporates, be sure to seal it tightly after use. If the viscosity increases due to solvent evaporation, dilute it to the proper concentration with Taseto Silver Thinner.

Test results

Rust preventive test

| Test Condition Prevention | Application times | Rust Period | |

| Moisture resistance test | Temperature 30° C Humidity 100% | 1 time | No rusting at all: about 1 month Occurrence point rust: about 1-3 months |

| 3 times | No rusting at all: about to 2 months Occurrence point rust: about 2-5 months | ||

| Exposure test | Indoor exposure | 1 time | No rusting at all : about 6 months Occurrence point rust : about more than 6 months |

| 3 times | No rusting at all: about more than 6 months Occurrence point rust: none | ||

| Outdoor exposure (Kawasaki coastal industrial area) | 1 time | No rusting at all: about 1 month Occurrence point rust: about 1 -4 months | |

| 3 times | No rusting at all: about 3 months Occurrence point rust: about 3-6 months | ||

※ Application is done with brush painting

(1 time coating, coating film thickness about 7 μ)

Weld performance test

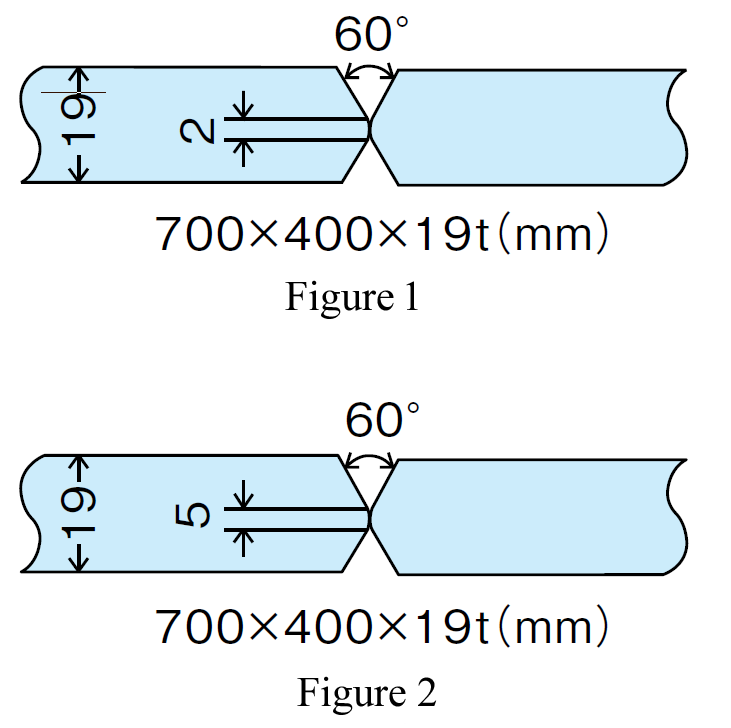

Materials and welding conditions

| Condition / Method | Arc Welding | Carbon dioxide gas welding | Submerged welding |

| Base metal | SS400 | SS400 | SS400 |

| Groove shape | Figure 1 | Figure 1 | Figure 2 |

| Welding material | D4301 4.0φ | YGW-11 1.6φ | YS-S3 4.0φ |

| Flux | – | – | FS-FG1 |

| Current (Amp) | 160~180 | 220~250 | 650~700 |

Weld test result

| Test item/ test conditions | arc welding | CO welding | Submerged welding | ||||

| Coating fabric-free | coating | paint | Cloth- free coating | paint | cloth-free coated | ||

| Tension test | Tension Strength kg/mm2 | 49.5 | 49.4 | 49.6 | 49.8 | 49.7 | 49.7 |

| Breakpoint | perform | perform | perform | perform | perform | perform | |

| Bending test | Free bending | good | good | good | good | good | good |

| Side bending | good | good | good | good | good | good | |

| Impact test (22 ° C kg f · m) | 7.8 | 7.5 | 10.3 | 10.5 | 10.0 | 10.3 | |

| Radiation penetration test | pass | pass | pass | pass | pass | pass | |

Safety notes

1. Management based on Organic Solvent Poisoning Prevention Rules etc. is required.

a. Provide local exhaust ventilation at the handling work area.

b. Please do not spill when you put in and out of a container.

c. Do not touch the skin during handling as much as possible, and wear a gas mask, air-permeable mask, protective gloves, etc. as necessary.

d. After handling, please wash your hands well.

e. Please set a certain place and store it.

2. Tacetil silver, tasto silver S, tasto silver A, and tasto silver A2 are flammable. So be careful with the fire.

3. In the case of aerosol products, please do not save if it is over 40 ℃. Also, used aerosol Please dispose of the can at the bottom of the opening.

4. For safety management, observe the precautions described in the product and refer to the safety data sheet (SDS) please.

List of related regulations

| Types | Prevention of Organic Solvent Poisoning rules | Poison, Deleterious Substances Control Law | Specified chemical substances | Fire Service Law hazardous material |

| SILVER | Second type organic solvents | Not applicable | Second like substances | The fourth class first petroleum |

| SILVER S | 〃 | 〃 | 〃 | 〃 |

| SILVER A | 〃 | 〃 | 〃 | 〃 |

| SILVER A 2 | 〃 | 〃 | 〃 | 〃 |

Related Products

-

Super Tool KPH27/32/36 Offset Wrench For Shear Bolt Use (With Corn Shaped Spear, 70° Type)

-

TONE BT-H Series Hex Bit

-

Murata Support tube STK400

-

Seiwa E01C11T (Soft Type) Clip-on Mounting EMC Products

-

Toho Seisakusho Forced Opening/Closing Type Proportional Control Motor

-

Sanritsu Electric CS19 The JIS-Certified Welding Rod Holder