Japan, UHT CORPORATION

UHT CORPORATION Laser Puncher LP-S□D series Laser

Made in Japan

Manufacturer: UHT CORPORATION

Model: LP-2S208DJ / LP-2S208DK/ LP-2S108DJ / LP-2S108DK

Features

- Green sheets, materials for ceramic substrates and green sheet laminates

- Speed-up is achieved by an optics system of original scanning control.

Galvo speed 2000PPS - Ultra-compact, automated all-in-one design

Small footprint of 1.7 m2

Lightweight 1500 kg structure - Series development matched to hole diameter and processing conditions.

- Low running cost

Sealed-off CO2 laser oscillator

Characteristics

- – The original optical scanning system controller and digital galvo scanner allow high-speed and high-accuracy processing.

- Scanning area : □50mm (LP-S208D) □30mm (LP-S108D) Max. processing area in conjunction with XY stage : □220mm

- -Series lineup

- Microvias down to 50 um in diameter (Type LP-S108D)

Guide hole trepanning (all types) - -Ultra-compact, automated all-in-one design for easy installation and relocation

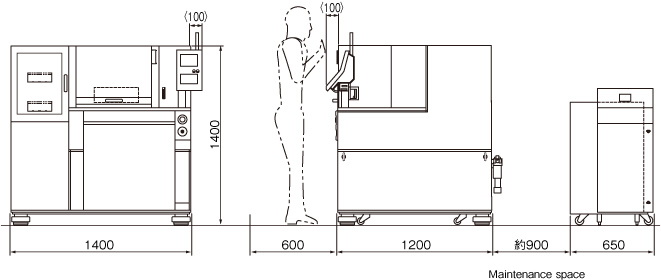

- Small footprint of 1400 (L) * 1200 (W) mm, 1.7 m2 Lightweight 1500 kg structure for easy relocation

- -High-stability and high-power CO2 laser

- Low running cost by adopting a sealed-off laser with long gas exchange intervals

- -Safety

- Class-1 laser product in compliance with JIS

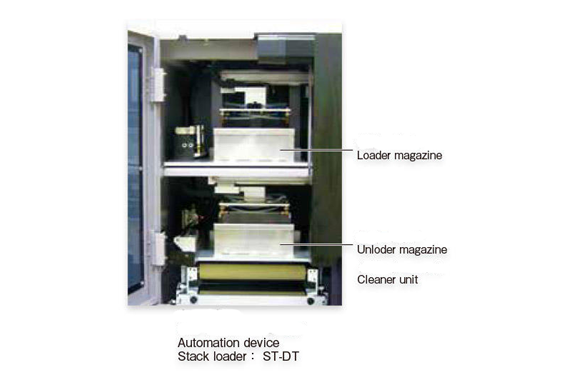

- -Accommodating automation (OP.)

- The cleaner unit can be installed. (OP.)

Suction table to customized processing pattern

Standard Specifications

| Model | LP-S208DJ | LP-S208DK | LP-S108DJ | LP-S108DK | |

|---|---|---|---|---|---|

| Work | Material | Ceramic green sheet(with or without PET film) | |||

| Punching area | Max.□220mm(rectangle also available) | ||||

| Externals・ Thickness | Max.□230mm(rectangle also available);Max.0.5mm | ||||

| Machining (Processing) | Hole size | φ70~200μm | φ50~150μm | ||

| Mask change type(dependent on material, thickness, parameters) | |||||

| Method | Mask imaging(Max.12 masks can be set.) | ||||

| Table | Suction table | ||||

| Capability | Punching accuracy | ±20μm(Image processing accuracy is included.) | |||

| Galvo speed | 2000PPS(X axis 0.5mm pitch) | ||||

| Laser unit | Oscillator | RF excitation CO2 laser | |||

| Wave length | 10.6μm | 9.4μm | 10.6μm | 9.4μm | |

| Average output | 250W | 225W | 250W | 225W | |

| Cooling method | Water-cooled by special chiller set outside machine | ||||

| Optical unit | Number of processing heads | 1head | |||

| Method | Galvanometer optical scanning system | ||||

| Scanning area | Max.□50mm | Max.□30mm | |||

| Laser focus adjustment | Electric Set by software | ||||

| Z axis | Automatic focus adjustment of optical unit by work thickness setting | ||||

| Image processing | Method | CCD cameras detect alignment marks on sheet surface. | |||

| Detection method | Binary centroid calculation / pattern matching | ||||

| Image processing camera | Two | ||||

| Camera view | Narrow view:1.2×0.9mm Wide view:4.8×3.6mm | ||||

| Lighting | LED ring lighting (standard: red, OP:white,blue,green) | ||||

| Control | Control unit | UHT original controller | |||

| Operation | 6.5inch color touch panel | ||||

| Data editing | Dedicated software (on stand-alone PC) | ||||

| Data memory capacity | Max.100,000 positions per file | ||||

| Network | Transmission of processing data from PC to machine via LAN. Up to 4 machines are manageable from PC. | ||||

| Dust collector(set outside machine) | From above/below workpieces and inside the machine by dedicated dust collector | ||||

| Dust proof measures | Air purge system inside optical unit, fθ lens protective glass, axis covers | ||||

| Safety device | Safety cover, Key switch, Safety interlock | ||||

| Laser display light | 2 colors of LED | ||||

| Laser class | Class-1 laser product in compliance with JIS | ||||

| Power source | 3φ AC200V ±10% 5kVA | ||||

| Air source | 0.4~0.7MPa(Clean air) | ||||

| Automation module | ST-DT(stack loader) | ||||

| Machine | Size | W1400×D1200×H1400mm | |||

| Weight | Approx. 1500kg | ||||

| Working condition | Temperature | 10~35℃(22±2℃ recommended) | |||

| Humidity | 40~60%(Non-dewing) | ||||

| Vibration | There must be neither impact nor a vibration. | ||||

Options

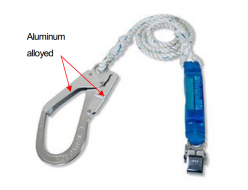

- Mask

nominal dia: 1.4 – 4.0 mm, 0.1 mm increments, sizes to be specified(Square masks available) - Alignment & suction table

- Laser energy measurement function

- Cleaner unit

- *Power box

- *CAD conversion software

- *Control PC & Processing data creation software

*Items with an asterisk are required for the first machine.

Outline Drawing

Example of floor layout