- Home

- Products

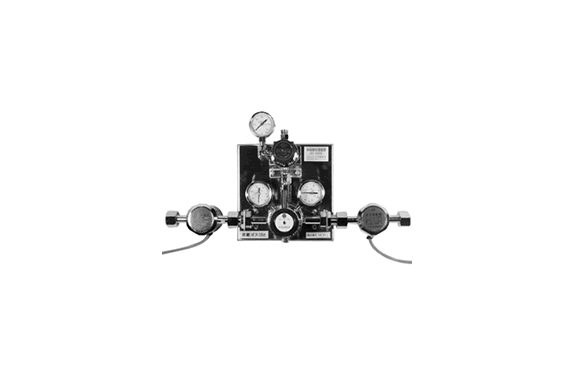

- Chiyoda Seiki CH-100A Semi-automatic Switching Gas Supply Device (Standard flow rate: 50ℓ/min/Air) (for carbon dioxide gas)

Chiyoda Seiki, Japan

Chiyoda Seiki CH-100A Semi-automatic Switching Gas Supply Device (Standard flow rate: 50ℓ/min/Air) (for carbon dioxide gas)

Made in Japan

Manufacturer: Chiyoda Seiki

Feature

The semi-automatic switching device is a gas collecting device with two container lines A and B. Two regulators are connected in parallel to each system of the A and B lines, and each secondary pressure By adding a differential pressure to the set value, the gas starts to flow from the container line (A) with the higher set value, and when the remaining amount of gas in that container line (A) becomes low, the flow rate will remain the same and the other line will automatically flow. A supply device designed to switch the supply line to the container line (B).

Replace the empty container in the container line (A) where gas has been consumed with a container filled with gas, and rotate the switching lever 180° (CH-100 type) (SC-15-B type) (LC-140 type) or by moving the adjustment handle (CH-140 type), the variable secondary pressure of the container line (B) becomes higher than that of the container line (A), and stable gas supply is performed from the container line B, When the remaining amount of gas in the container line (B) is low, the gas will automatically start flowing from the line (A). Similarly, by replacing the empty container in the container line (B) where the gas has been consumed with a container filled with gas and operating the switching lever or the adjustment handle, the variable secondary pressure in the container line (B) is increased. , is lower than the container line (A), and gas is supplied more stably than the container line A. “By repeating this procedure, it is possible to supply gas continuously.”

●In addition, by installing a pressure gauge with a lower limit contact on the primary side and connecting it to the alarm panel, the gas supply line can be switched. A buzzer and patrol lamp inform you of the situation, so it is convenient for container replacement

Replace the empty container in the container line (A) where gas has been consumed with a container filled with gas, and rotate the switching lever 180° (CH-100 type) (SC-15-B type) (LC-140 type) or by moving the adjustment handle (CH-140 type), the variable secondary pressure of the container line (B) becomes higher than that of the container line (A), and stable gas supply is performed from the container line B, When the remaining amount of gas in the container line (B) is low, the gas will automatically start flowing from the line (A). Similarly, by replacing the empty container in the container line (B) where the gas has been consumed with a container filled with gas and operating the switching lever or the adjustment handle, the variable secondary pressure in the container line (B) is increased. , is lower than the container line (A), and gas is supplied more stably than the container line A. “By repeating this procedure, it is possible to supply gas continuously.”

●In addition, by installing a pressure gauge with a lower limit contact on the primary side and connecting it to the alarm panel, the gas supply line can be switched. A buzzer and patrol lamp inform you of the situation, so it is convenient for container replacement

Specifications

| Applicable gas | O2, N2, Ar, Air,H2 He, CO2, C2H2, CH4 Ar+CO2, Laser processing mixed gas | |

Primary pressure | Design | 16,2 |

| Normal use | 14,7 | |

Secondary Pressure | Design | 1,7 |

| Normal use | 0,8 | |

Tertiary pressure | Design | 0,65~0,95 |

| Normal use | 0,6 | |

| Flow rate (standard condition) | 0,1~0,5 | |

Main material | Regulator | C3771B |

| Diaphragm | CR | |

| Valve | C3771B | |

| Piping | C1220T | |

| Connecting pipe | C1220T | |

| Panel | SUS304 | |

| Main joint | W22山14 | |

| Exit joint | Rc1/4 | |

| Weight (panel set) | 6,5 kg | |

Related Products

-

Watanabe TW-1L Distributor (non-isolated) – Signal Converter

-

Kitz 20UPA,20UPAM Stainless & High Alloy 20K Globe Valve

-

Gentos CP-R168WH Compact Desk Light (240 lumens)

-

Watanabe M-2 Multiplier

-

Chiyoda Seiki Semi-automatic Switching Type Cardle Receiving/decompressing Device For H2

-

Kobata Drip-Proof Type Pressure Gauges