Air Knocker, Exen

EXEN RKD120P Air Knocker (Direct Type)

Products Made In Japan

Manufacturer: EXEN

Model: RKD120P

Direct-type hammer ring equipment for widespread applications

It has been used in this way

01. Food factory RKD used when removing chocolate from formwork in a chocolate factory.

02. Elimination of wall adhesion of tumble dryers

03. Excess paint removal for powder coating

04. Prevention of wall surface adhesion for heating furnaces, knocking off welding sputtering, and prevention of workpiece adhesion on the mesh in the drying furnace

05. Used for engraving

06. Moisture drop of the base

Features

The air-type relay knocker series (direct type) is a unique device in which the piston directly forces the hopper wall surface etc. with the force of compressed air, and the impact eliminates the adhesion and blockage prevention of powders. In addition, since it can be used only by air supply, it is excellent in safety and economy and can be used with peace of mind without hindrance to powders with the property of sticking when centralistic force is given. The case of the vibe type, it is a type that strikes the fixed position knocker base attached, but it can hit what comes moving, move the knocker itself to hit, and the application will spread with one idea. In addition, it can be used in the same way as the vibe type.

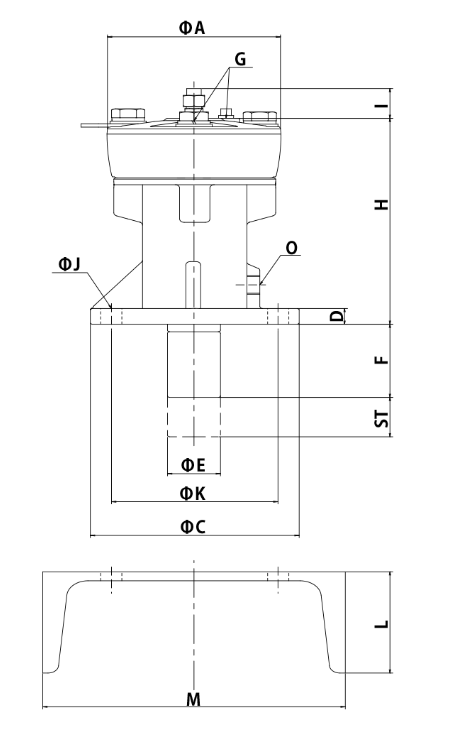

Dimensions, installation and operation panel

Product dimension diagram

High-strength adoption improves durability

The blow force can be varied by adjusting the supply air pressure.

Relay piping of multiple simultaneous use is possible.

Oil-free, drive-free and eco-friendly

Simple construction and high durability

Large knocker to eliminate blockages

Knocker mounting method

Operating principle of relay knocker

1. Compressed air flowing into the knocker is first supplied to the valve chamber, and the umbrella valve is pushed down and stored in the storage chamber.

2. When the three-way valve is activated to exhaust the air in the valve room, compressed air in the storage chamber moves the umbrella valve up.

3. When the umbrella valve moves, compressed air in the storage chamber pushes the piston down and hits the base surface.

Its impact force eliminates adhesion and blockage of powders.

Specification

| Model | Pressure used (MPa) | Strike cycle (times/min) | Air consumption (L/time (ANR)) | Strike Energy (N/m) | Impact force | Mass (kg) | |

|---|---|---|---|---|---|---|---|

| (kg/m/s) | Equivalent Hammer (pounds) | ||||||

| RKD30PA | 0.3 ~ 0.7 | 1~60 | 0.05~0.13 | 5.5~13.1 | 1.2~1.8 | 1 or less | 2.1 |

| RKD40PA | 0.15~0.37 | 9.22~22.3 | 2.6~4.0 | 1~1.5 | 5.6 | ||

| RKD60PA | 0.33~0.77 | 20.6~49.0 | 6.9~10.6 | 1.5~3 | 13.1 | ||

| RKD80PA | 0.60~1.40 | 45.1~109 | 15.2~23.7 | 3~8 | 18.4 | ||

| RKD100PA | 0.98~2.28 | 82.4~201 | 30.0~46.9 | 6~15 | 35.5 | ||

| RKD120P | 1~6 | 3.32~6.64 | 131~321 | 52.0~84.0 | Twice the equivalent of 100PA | 52. | |

Product

| Model | φA | φC | D | φE | F | G | H | I | φJ | φK | ST | L | M | O | Use Tube diameter |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RKD30PA | 66 | 70 | 8 | 15.0 | 38 | Rp1/8 | 95 | (25) | 9.0 | 55 | 17 | 50 | 100 | Rp1/4 | φ8Xφ6 |

| RKD40PA | 86 | 95 | 12 | 23.5 | 55 | 140 | 13.0 | 70 | 25 | 75 | 150 | ||||

| RKD60PA | 115 | 138 | 14 | 35.0 | 65 | 183 | 15.0 | 110 | 35 | 90 | 200 | Rp3/8 | |||

| RKD80PA | 146 | 148 | 16 | 47.5 | 60 | Rp1/4 | 222 | (28) | 17.0 | 120 | 40 | Rp1/2 | |||

| RKD100PA | 175 | 208 | 20 | 54.5 | 50 | 270 | 21.0 | 170 | 50 | 250 | Rp3/4 | ||||

| RKD120P | 220 | 235 | 21 | 68 | 43 | 326 | 17.5 | 198 | 47 | 300 | 2-Rp3/4 |

Installation method

Tightening torque table Unit: N/ m

| Nut size | *M6 | M8 | M10 | M12 | M14 | M16 | M20 | |

|---|---|---|---|---|---|---|---|---|

| Tightening torque | Bottom nut | *4.8 | 10.8 | 20.6 | 35.3 | 56.9 | 84.3 | 167 |

| Top nut | *4.8 | 7.6 | 14.4 | 24.7 | 39.8 | 59.0 | 117 | |

* When fixing the main body with the included bolts, spring washers, and hard lock nuts, please protect the tightening torque. If the tightening torque is weak, the nut may loosen due to the impact during operation.

※ For fall prevention, suspend and fix the main body with the attached fall prevention wire and shackle. Be sure to prevent loosening of the screw with wire, etc. on the screw part of the shackle.

Related Products

-

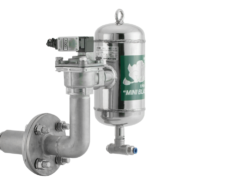

EXEN EMB1.5-3A Mini Blaster (100V)

-

EXEN HC116B Water-resistant Inverter

-

Seiwa E04SR130525AB SR, SRM and SRS Types Split Cores

-

Seiwa E04SRS200917S Ferrite Core Split Cores SR, SRM and SRS Types EMC Products

-

Seiwa E01J1511Y Automatic Mounting Finger EMC Products

-

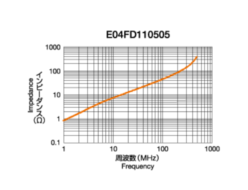

Seiwa E04FD110505 FD Type Ferrite Cores for FPC