Fukuda Seiko, Japan

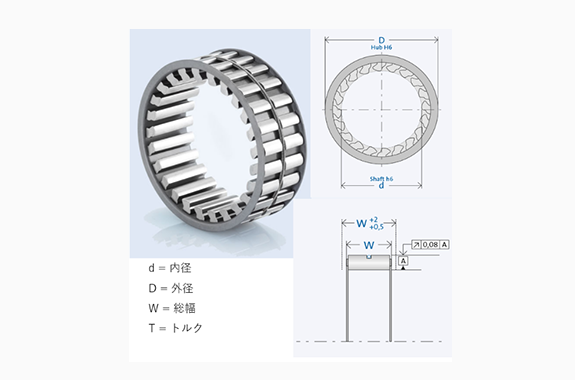

Fukuda FE 80 Series Type GMN Clutch

Made in Japan

Manufacturer: Fukuda Seiko

Model: FE 80 Series : FE 8072 Z 25/ FE 8000 Z

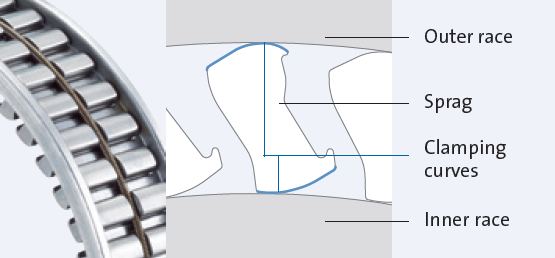

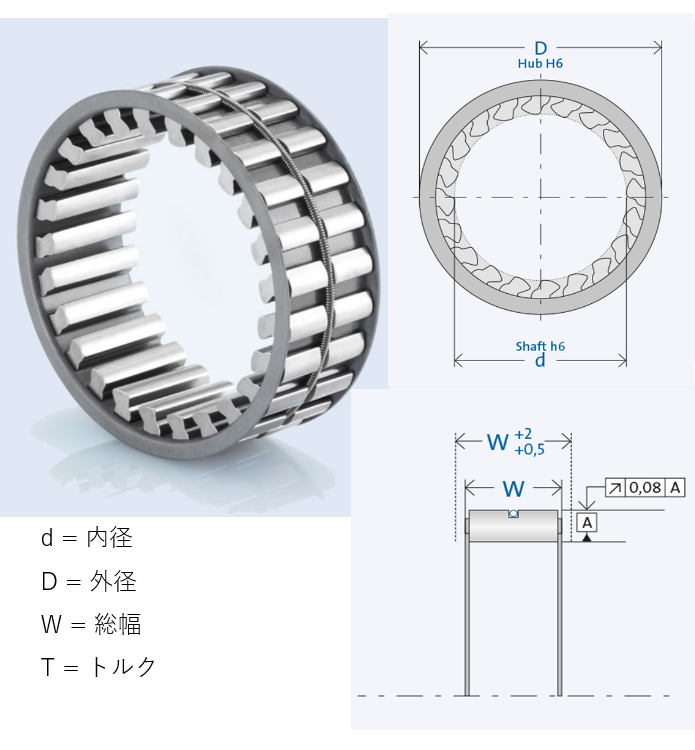

Developed by GMN, which has been dealing with machine component parts for more than 100 years, this is a lightweight, space-saving, and high-torque one-way clutch. A mechanism of the ring fastening part called a sprag controls the direction of rotation.

Use

Printing Machinery

Conveyor

E-bikes (electrically power assisted bicycles)

Compressor

Winch

Generators

Emergency power supply equipment and fire doors

Wheelchair

Features

Suggestions for backstops, indexes, and overrunning

Space-saving and high torque

High-speed swivel motion

High-precision positioning

Minimal moment of inertia

Uniform load distribution due to individual sprag movements

High design freedom with various options: with inner and outer rings, with axle reception, with keyway, with lubrication and seals

Summary

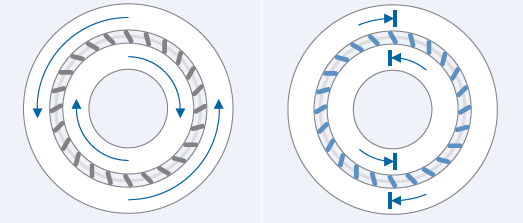

A one-way clutch is a clutch mechanism that transmits power in only one direction, and GMN uses a sprag-type mechanism.

Idle direction Power transmission direction

The friction force generated when the uniquely designed sprag is upright around the entire circumference controls the direction of rotation. Since a static friction force is generated around the entire circumference, both high torque and space saving are achieved.

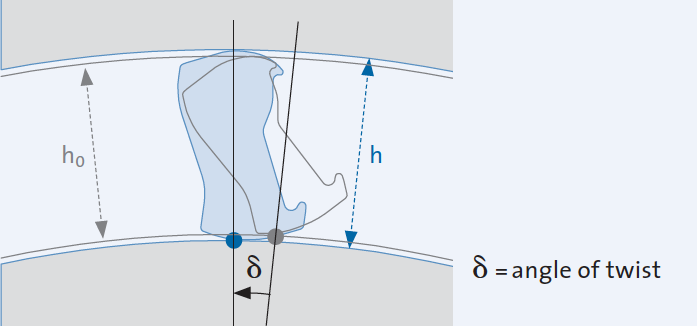

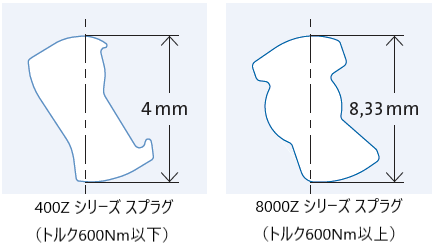

The slight rotation of the tilt angle of δ minutes makes the splug stand upright.

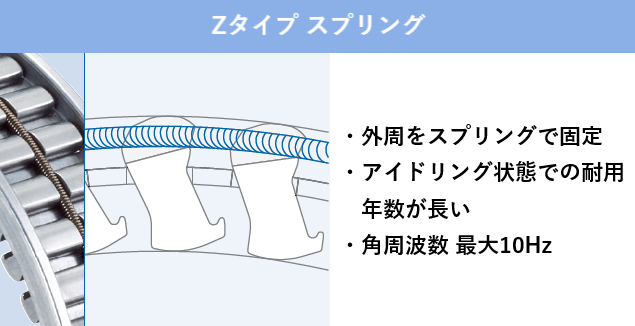

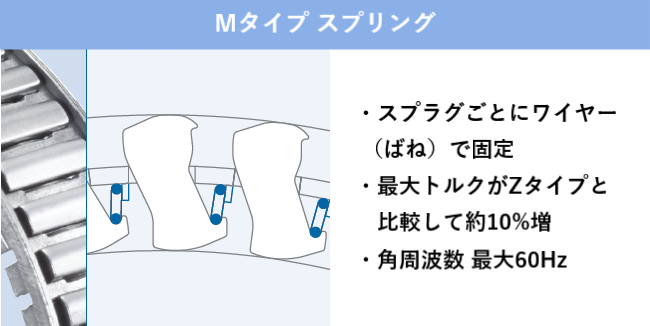

There are two types of spring structures that fix the splugs, Z type and M type, and use the M type for applications where the angular frequency (angular frequency) is greater than 10 Hz.

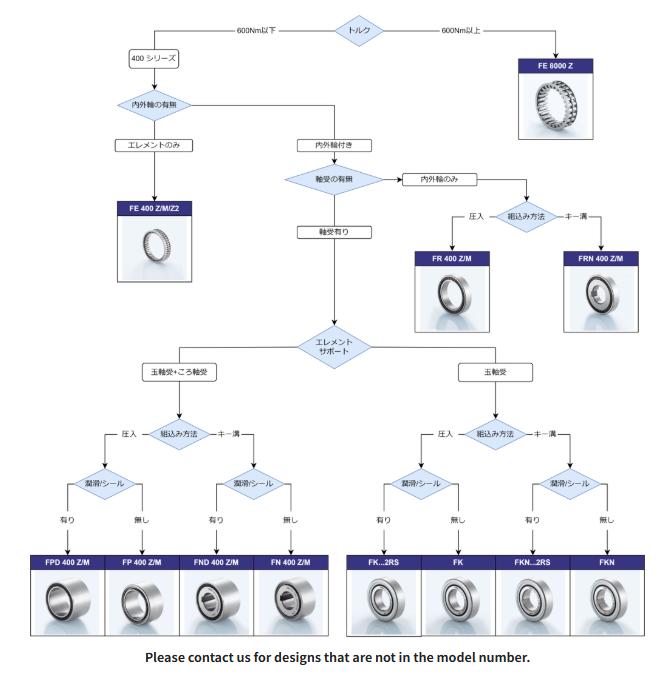

You can choose the best clutch from a variety of designs + options.

Components:

Sprags

Spring: tension spring

Cage: steel / plastic

Lubrication: Oil or grease

Width/installed width: 11 mm / 12 mm

Operating temperature:

Max. 170°C (steel cage)

Max. 140°C (plastic cage)

FE 8000 Z type (insert element)

Specifications

Built-in dimensions: 16/19/25 mm (axial)

Shaft diameter: 38.09~220 mm

Heat resistance: up to 170°C

Index feed cycle: up to 5 Hz

Lubrication: oil or grease

Recommended Finish Tolerance

Axis: h6

Housing: H6

Recommended Finish Tolerances

Axis / Housing: Steel, HRC 60+4 (HV 700+100)

Ehd ≥ 1.3 mm, Rz ≤ 2.5 μm

FE 8000 Z Type Model List

| Model No. | d [mm] | D [mm] | W [mm] | Tnom [Nm] | Weight [kg] |

| FE 8038 Z 16 | 38.09 | 54.75 | 16 | 609 | 0.082 |

| FE 8038 Z 19 | 38.09 | 54.75 | 19 | 801 | 0.096 |

| FE 8040 Z 16 | 40.00 | 56.66 | 16 | 668 | 0.084 |

| FE 8040 Z 19 | 40.00 | 56.66 | 19 | 880 | 0.102 |

| FE 8044 Z 16 | 44.45 | 61.11 | 16 | 799 | 0.091 |

| FE 8044 Z 19 | 44.45 | 61.11 | 19 | 1.052 | 0.112 |

| FE 8049 Z 16 | 49.72 | 66.38 | 16 | 923 | 0.100 |

| FE 8049 Z 19 | 49.72 | 66.38 | 19 | 1.201 | 0.118 |

| FE 8050 Z 16 | 50.00 | 66.66 | 16 | 942 | 0.100 |

| FE 8050 Z 25 | 50.00 | 66.66 | 19 | 1,237 | 0.123 |

| FE 8054 Z 16 | 54.76 | 71.42 | 16 | 1,080 | 0.107 |

| FE 8054 Z 19 | 54.76 | 71.42 | 19 | 1,424 | 0.128 |

| FE 8054 Z 25 | 54.76 | 71.42 | 25 | 2,015 | 0.172 |

| FE 8060 Z 16 | 60.00 | 76.66 | 16 | 1,243 | 0.113 |

| FE 8060 Z 19 | 60.00 | 76.66 | 19 | 1,560 | 0.141 |

| FE 8060 Z 25 | 60.00 | 76.66 | 25 | 2,111 | 0.188 |

| FE 8072 Z 16 | 72.21 | 88.87 | 16 | 1,740 | 0.135 |

| FE 8072 Z 19 | 72.21 | 88.87 | 19 | 2,145 | 0.163 |

| FE 8072 Z 25 | 72.21 | 88.87 | 25 | 2,918 | 0.220 |

| FE 8079 Z 25 | 79.69 | 96.36 | 25 | 3,295 | 0.227 |

| FE 8080 Z 16 | 80.00 | 96.66 | 16 | 1,848 | 0.141 |

| FE 8080 Z 19 | 80.00 | 96.66 | 19 | 2,278 | 0.176 |

| FE 8080 Z 25 | 80.00 | 96.66 | 25 | 3,101 | 0.235 |

| FE 8083 Z 25 | 83.34 | 100.00 | 25 | 3,640 | 0.245 |

| FE 8100 Z 16 | 100.00 | 116.66 | 16 | 2,632 | 0.188 |

| FE 8100 Z 19 | 100.00 | 116.66 | 19 | 3,303 | 0.228 |

| FE 8100 Z 25 | 100.00 | 116.66 | 25 | 4,535 | 0.306 |

| FE 8103 Z 16 | 103.23 | 119.89 | 16 | 2,887 | 0.184 |

| FE 8103 Z 19 | 103.23 | 119.89 | 19 | 3,582 | 0.290 |

| FE 8103 Z 25 | 103.23 | 119.89 | 25 | 4,920 | 0.300 |

| FES 8123 Z 25 | 123.34 | 140.00 | 25 | 6,600 | 0.370 |

| FE 8123 Z 25 | 123.88 | 140.54 | 25 | 6,604 | 0.370 |

| FE 8126 Z 25 | 126.22 | 142.88 | 25 | 6,744 | 0.375 |

| FE 8140 Z 25 | 140.00 | 156.66 | 25 | 7,388 | 0.410 |

| FE 8150 Z 25 | 150.00 | 166.66 | 25 | 8,272 | 0.440 |

| FE 8160 Z 25 | 160.00 | 176.66 | 25 | 9,096 | 0.470 |

| FE 8180 Z 25 | 180.00 | 196.66 | 25 | 10,463 | 0.520 |

| FE 8220 Z 25 | 220.00 | 236.66 | 25 | 14,060 | 0.640 |

Related Products

-

Watanabe A7000 Series A7□1A Digital panel meter for load cells

-

Kurimoto CFM-16 Forging Press

-

Gentos BL Series RL-00R Dry Battery Bike Light

-

Vessel No.IPC-V4 Ion Parts Cleaner Vertical Type

-

Nakatani Kikai FR00 Sand Rammer (Bench Type – Table Work)

-

LOBTEX BP L-type Clamp (Bar Handles Super Strong Type)