Fukudaco, Japan

Fukudaco AE Sensor

Manufacturer: Fukudaco

Overview

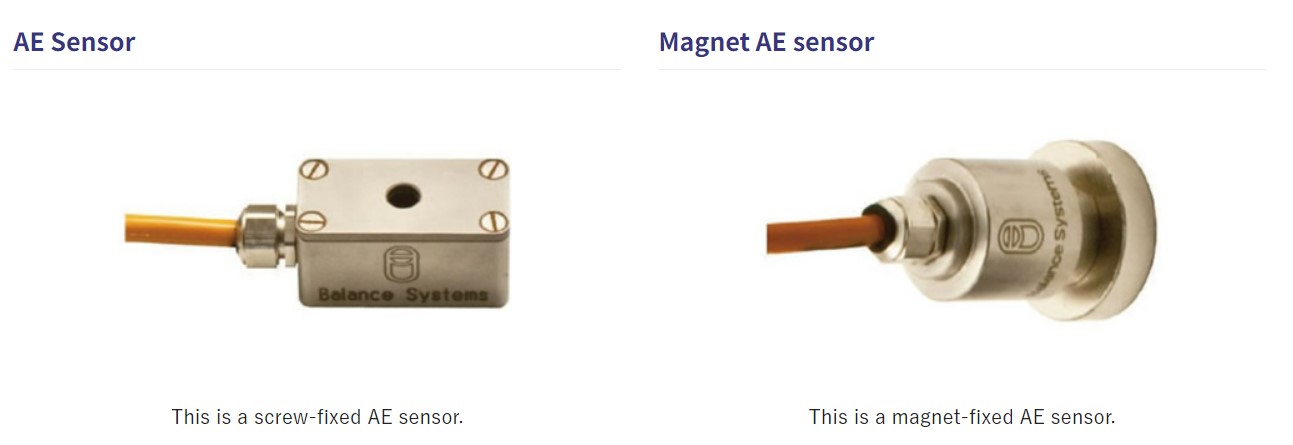

We offer a variety of shapes, including fluid detection and non-contact types. These AE sensors detect contact between the workpiece, grinding wheel, and dresser.

Applications

- Various types of grinding machines

Features

- Customizable

- High-speed digital processing

- Equipped with high-end logic such as FFT analysis

AE Sensor Product List

The AE sensors from Balance Systems, equipped with FFT functionality, enable more detailed processing analysis. These sensors detect high-frequency vibrations that are imperceptible to the human ear. Due to their high sensitivity, they are used not only for contact detection as gap eliminators but also for dressing processes and grinding process monitoring, thereby providing visualization of the grinding process.

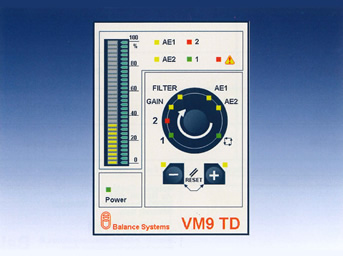

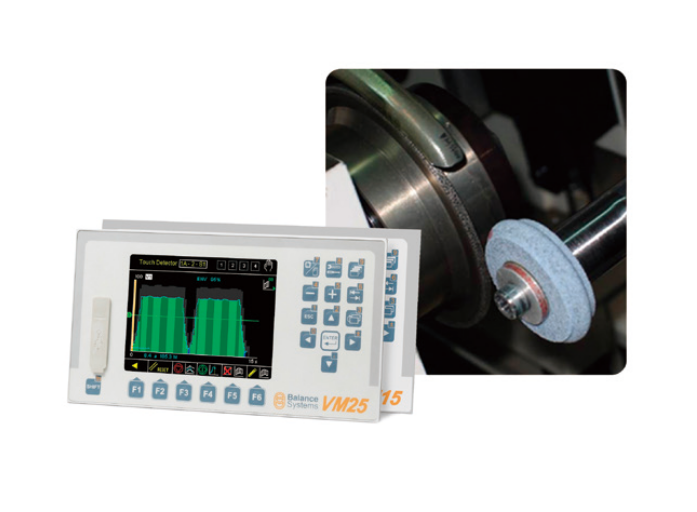

Controller

The VM25 controller is a rack-type controller that can expand its logic boards according to the required functions. With over 30 types of boards available, the controller offers both panel-type displays and Windows software for operation. It integrates process monitoring, balancing, and gauging, enabling more efficient control and significantly enhancing the added value of machines.

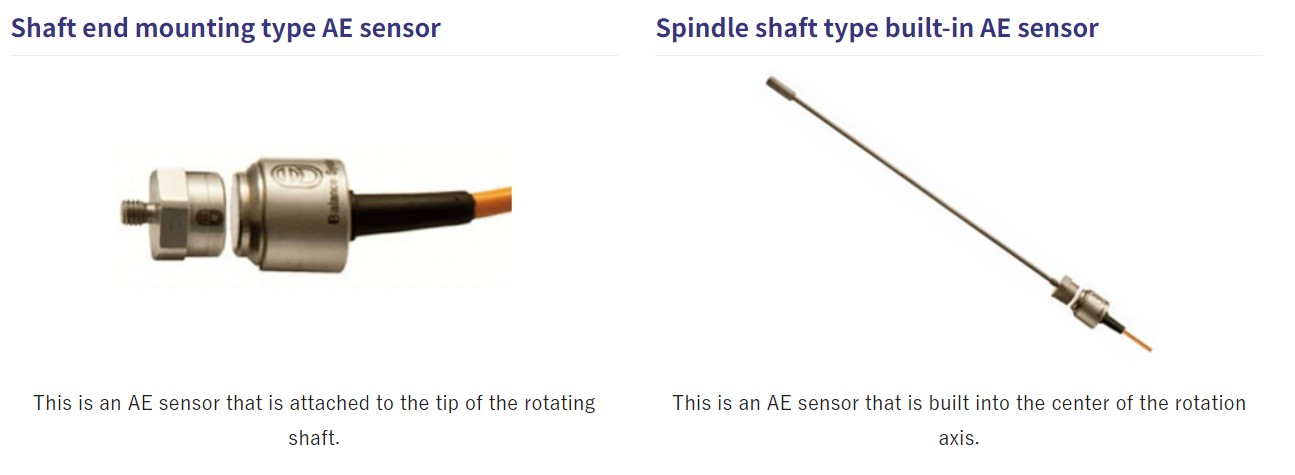

When Using AE Sensors Individually

AE sensor dedicated controller VM9TD

AE sensor dedicated controller VM9TD

When using the AE sensor in combination with other products

High-performance multifunction controller VM25

High-performance multifunction controller VM25

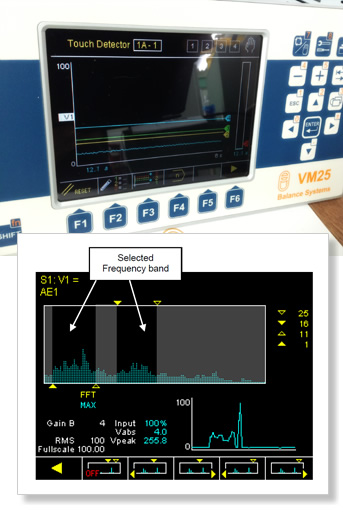

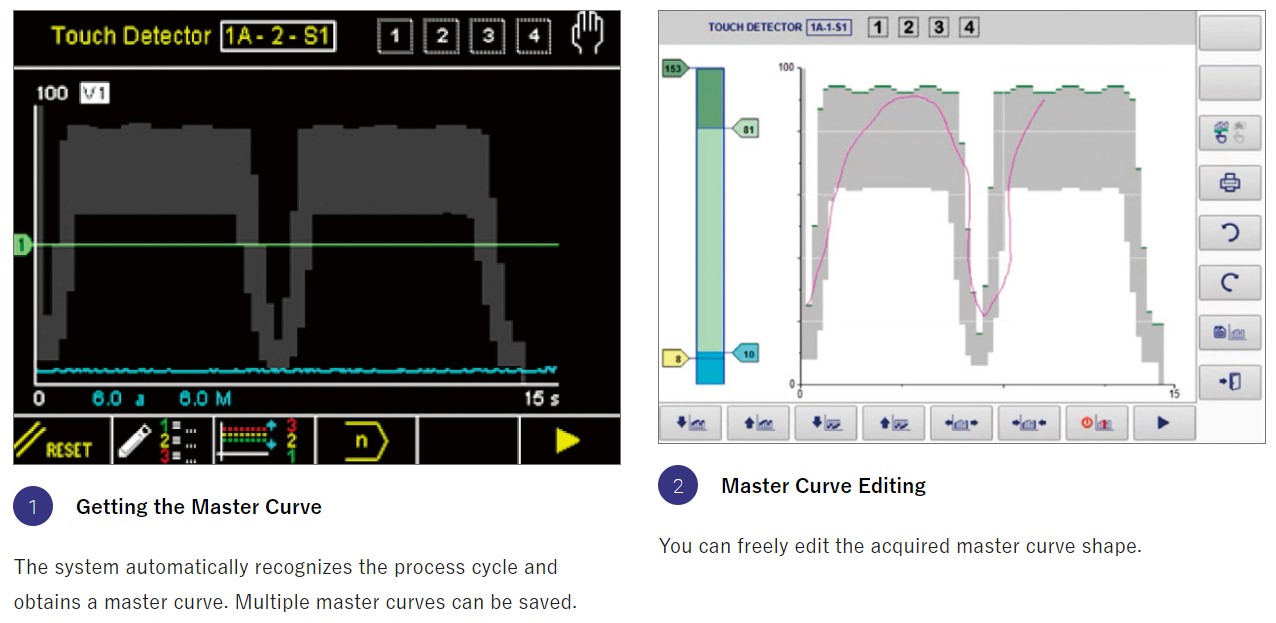

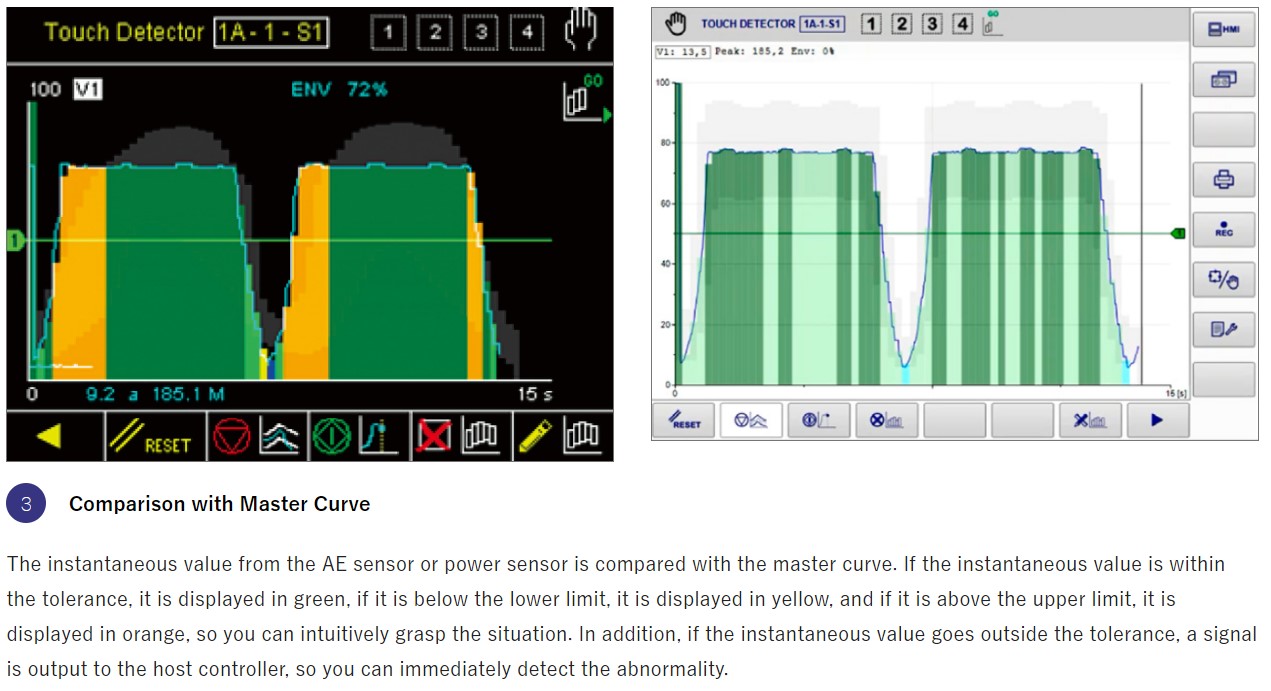

AE Signal Envelope Function

Using AE sensors and power sensors allows for effective monitoring of grinding and dressing processes, thereby enhancing the overall performance of the grinding machine. By comparing the master curve, obtained from pre-registered AE and power sensors, with the actual signal levels during grinding, it is possible to determine the optimal completion of grinding and dressing processes and output this information to a higher-level control device. The newly developed envelope function maximizes grinding process efficiency.

Benefits

- Monitoring the shape of the grinding wheel during the dressing cycle

- Monitoring the grinding process

- Reducing processing time

- Extending the lifespan of the grinding wheel (both general and profile)

Features

- Supports up to 256 time zones (comparison of master curves and instantaneous values in each zone)

- Four threshold settings

- Auto start via a trigger signal

- Self-learning of cycles

- Contact and collision control

- Automatic control via NC (digital I/O, Profibus, Profinet)

- Flexible editing of master curves

- Compatible with both operation panels and HMIs

- Compatible with both VM15 and VM25 series

- Capable of processing two processes simultaneously

- Can store up to 16 part programs

Compatibility

You can integrate the envelope function into your existing VM25 and VM15 systems.

Functionality

During the process of comparing with the master curve, the display actively shows whether the AE signal level remains within the allowable range for each time zone. Simultaneously, it sends real-time signals to the higher-level controller, enabling immediate action in case of abnormalities. At the end of the process, it outputs a judgment result, confirming whether the actual AE signal level stayed within the envelope’s allowable range across all time zones.

Furthermore, the envelope function includes contact detection and collision detection, continuously monitoring conditions in the background.

Additionally, with the traditional part program threshold settings enabled, you can execute accurate envelope monitoring using a dedicated trigger signal. You can choose the timing for acquiring and comparing the master curve from either a contact signal or an external trigger, thereby allowing application in various scenarios.

Operation panel/HMI software

Related Products

-

Gentos BL-B03 Dry Battery Bike Light (120lm / 1200cd)

-

HANKOKU BQ-PS Motor Siren (Three Phase)

-

Japan Life Hose Joint (Pipe To Connect With Grout Hose Of Anchor Plate)

-

YOSHITAKE GD-46KK Water Pressure Reducing Valve

-

Organo AM-C/AM-SR Regenerative Automatic Pure Water Systems

-

IMADA PSM series Precision Type Mechanical Force Gauge