Fukudaco, Japan

Fukudaco Insulated Bearings INSUTECT

Manufacturer: Fukudaco

Overview

INSUTECT® ceramic-coated bearings effectively counteract bearing currents. Through our global network, we ensure high-reliability insulated bearings with short lead times; moreover, some are available for immediate delivery.

*To address circulating currents, it is strongly recommended to use insulated bearings in conjunction with AEGIS® rings.

Applications

- Mitigation of circulating currents in inverter-controlled systems

- Shaft insulation for motors converted to inverter drive after installation

- Suitable for both deep groove ball bearings and cylindrical roller bearings

- Available for motors with 75kW or higher on the non-drive end, with stock available (62/6312C3 to 62/6320C3)

Features

- Plasma-sprayed with 100µm* of aluminum oxide on the outer surface of the bearing outer ring (*200µm coatings with superior insulation properties are also available)

- Dimensions finished to ISO tolerances

- It can be installed using the same methods as standard bearings

- Short lead times due to shipping from our metropolitan area stock management center

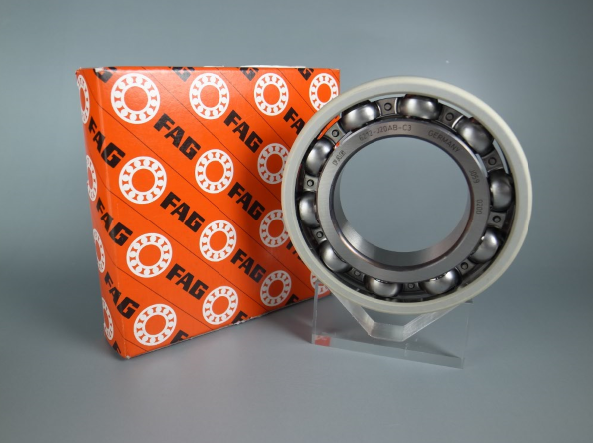

SCHAEFFLER Insulated Bearings

SCHAEFFLER’s insulated bearings feature a ceramic coating of aluminum oxide powder, plasma-sprayed at high temperature and speed on the outer circumference of the outer ring with a thickness of 100µm* (withstanding voltage VDC=1,000V). *We also stock types with 200µm thickness for enhanced insulation performance.

- Installation: Install these bearings using the same methods as standard bearings. The dimensions adhere to ISO 15 standards, so you can replace standard bearings with these to enhance shaft insulation without special modifications. Do not drop the bearings or damage the coating with sharp objects.

- Availability: We generally stock insulated types in sizes 6212C3 to 6220C3 and 6312C3 to 6320C3. Larger sizes, clearances, and cylindrical roller (NU type) bearings are also available. Please feel free to inquire.