Dia Electronics Application, Japan

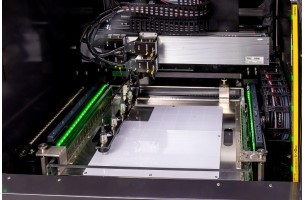

HYPER SCAN-M4 Ultrasonic Flaw Detection Multi-System

Made in Japan

Manufacturer: Dia Electronics Application

Model: SCAN-M4

Feature:

The HYPER SCAN-M4 ultrasonic inspection multi-system increases productivity with its multi-channel (2CH, 4CH) system. The HYPER SCAN-M4 also offers a full range of software functions to assist in the detection and recognition of defects.

Secifications:

| Usable probe | 5-150MHz |

| Effective measurement range | 350mm x 350m *Can be customized depending on the target work |

| Minimum inspection pitch | 20 μm |

| Maximum robot speed | 1000mm/s (not including acceleration/deceleration) |

| Equipment size | W970mm×D1130mm×H1480mm |

| others | Safety measures (light curtain), water tank lifting function |

Use Cases

Power modules

Defect detection inside modules

Inspection of solder joint layer on chip/circuit board

Inspection of solder joint layer of base plate/board

Inspection of adhesive resin layer between module and base board

Internal inspection of modules with fins

Ceramic Components/Composite Materials

Ceramic/metal (copper, aluminum) bonding layer inspection

Peeling inspection of electrostatic chuck materials

Inspection of bonding between metal substrate circuits/base

Crack inspection of ceramics.

Software Functions

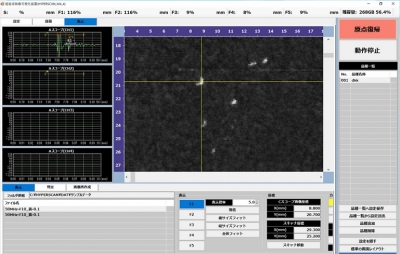

Partial magnification function When a range is specified in the flaw image, the area in question is enlarged and displayed.

Defect list display Binarizes defects within a specified range and displays a defect list.

Image display of selected defects Color image of selected defects is displayed on the image by specifying the defects in the list.

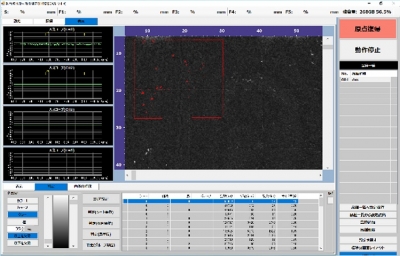

Dimension measurement function Measures the X,Y length of a rectangular range and the distance between two points.

≪Partial enlargement function≫

≪Specified range defect display≫

≪Rectangular length measurement≫

≪Distance measurement between two points≫

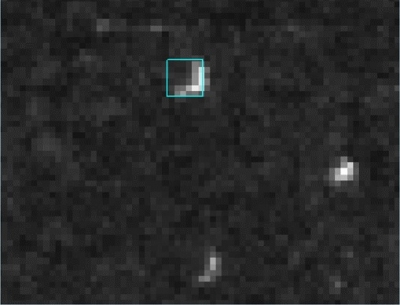

≪Ceramic crack≫

≪Power module solder voids≫

≪Ceramic substrate bonding failure≫