Japan, Kanetec

Kanetec KM MAGNETIC HOLDER

Product Made in Japan

Manufacturer: Kanetec

Model: KM (KM-0005,KM-0007,KM-H001,KM-H0015,KM-H002,KM-H0025,KM-0005L,KM-0007L,KM-0010H,KM-001,KM-T001,KM-0015,KM-T0015,KM-0018H,KM-002,KM-T002,KM-0025H,KM-T0025,KM-T003,KM-0010J,KM-0018J,KM-0025J,KM-025C,KM-03C,KM-04C,KM-05C,KM-07C,KM-08C,KM-025S,KM-06S)

Application

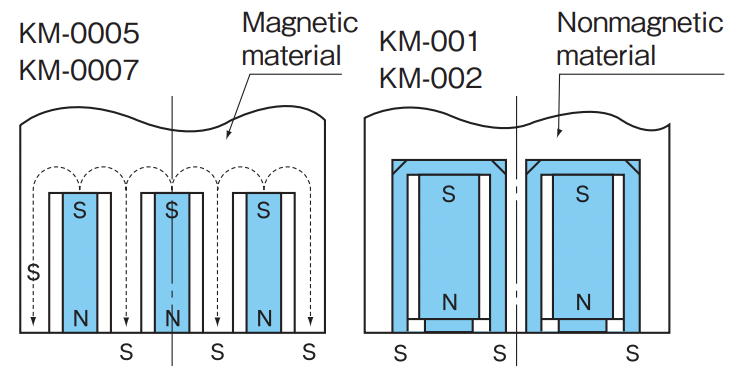

You can use it to hold down drawings, rules, and paper patterns.

The models with tapped holes on the back can be used widely by installing them on jigs.

Can be incorporated in press dies.

Can hold workpieces during wire cutting.

Features

- Six types of specifications; OD tolerance, plating, painting, peripheral knurling, stainless steel spec. and heat-resistance spec. are available for selection according to applications.

- By matching the OD “h” tolerance, the holders can be incorporated in dies.

- A tapped hole on the back makes the holders useful in various applications.

List of permanent magnetic holders

| Size | Height | OD “h” Tolerance | Plating | Painting | Peripheral Knurling | Stainless Steel Spec. | Heat-Resistance Spec. |

| Φ 5 | × 8 | KM-0005 | _ | _ | _ | _ | _ |

| ×13 | _ | KM-0005L | _ | _ | _ | _ | |

| Φ 7 | × 8 | KM-0007 | _ | _ | _ | _ | _ |

| ×13 | _ | KM-0007L | _ | _ | _ | _ | |

| Φ10 | ×8 | _ | KM-0010H | _ | KM-0010J | KM-0010H-SUS | _ |

| ×15 | KM-H001 | KM-001 | _ | _ | _ | _ | |

| ×18 | _ | KM-T001 | _ | _ | _ | _ | |

| Φ15 | ×15 | KM-H0015 | KM-0015 | _ | _ | _ | _ |

| ×18 | _ | KM-T0015 | _ | _ | _ | _ | |

| Φ18 | ×8 | _ | KM-0018H | _ | KM-0018J | KM-0018H-SUS | _ |

| Φ20 | ×15 | KM-H002 | KM-002 | _ | _ | _ | _ |

| ×18 | _ | KM-T002 | _ | _ | _ | _ | |

| Φ25 | ×10 | _ | KM-0025H | _ | KM-0025J | KM-0025H-SUS | _ |

| Φ26 | ×25 | KM-H0025 | _ | KM-025C | _ | _ | _ |

| ×30 | _ | KM-T0025 | _ | _ | _ | _ | |

| Φ30 | ×25 | _ | _ | KM-03C | _ | _ | _ |

| ×33 | _ | KM-T003 | _ | _ | _ | _ | |

| Φ40 | ×30 | _ | _ | KM-04C | _ | _ | _ |

| Φ40 | ×40 | _ | _ | _ | _ | _ | KM-T004T |

| Φ50 | ×40 | _ | _ | KM-05C | _ | _ | _ |

| Φ50 | ×45 | _ | _ | _ | _ | _ | KM-T005T |

| Φ70 | ×40 | _ | _ | KM-07C | _ | _ | _ |

| Φ80 | ×45 | _ | _ | KM-08C | _ | _ | _ |

| 26×26 | × 25 | _ | _ | KM-025S | _ | _ | _ |

| 26×60 | ×25 | _ | _ | KM-06S | _ | _ | _ |

※ The holding power may drop when the holder is worked on additionally. In particular, additional work in the radial direction has a large influence on the holding power and therefore, must be limited to a minimum necessary scope.

Embedded in a jig (Example)

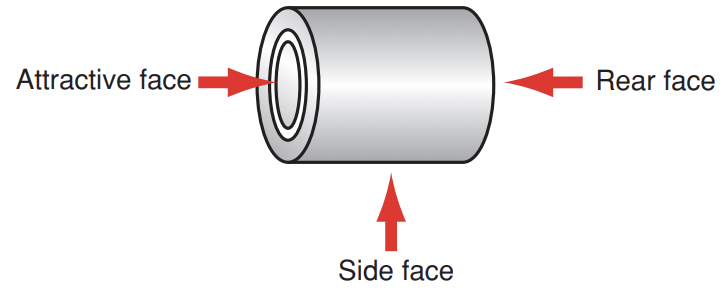

Names of faces

The upper limit of working temperature

The holding power drops as the body temperature rises. The following types are available. The original holding power returns to the original level when the temperature drops to normal temperature.

■Type A (Alnico magnet used)

Superior in terms of temperature. The holding power as high as 85% can be maintained at 350℃ when the holding power at 20℃ is 100%. This type can be used up to 400℃ intermittently for a short period.

■Type B (Samarium-cobalt type rare earth magnet used)

The holding power drops to about 95% at 100℃ and to about 85% at 200℃ when the holding power at 20℃ is 100%. For continuous use, the upper limit is 150℃, and for intermittent use for a short period, this type may be used up to 200℃.

■Type C (Neodymium rare earth magnet used)

The holding power drops to about 85% at 50℃ and to about 70% at 100℃ when the holding power at 20℃ is 100%. The upper limit for continuous use is 100℃.

OD “h” tolerance specification

| Model | Dimensions | Holding Power | Surface Treatment | Mounting Tapped Hole | ||

| OD x Height | h” tolerance | Height tolerance | ||||

| KM-0005 | φ * 5(0.19) * h * 7(0.27) * 8(0.31) | 0 -0.012 | 0 -0.1 | 0.3N (0.03kgf) | None | None |

| KM-0007 | φ* 7(0.27) * h * 7(0.27) * 8(0.31) | 0 -0.015 | 0.4N (0.04kgf) | |||

| KM-H001 | φ * 10(0.39) * h * 9(0.35) * 15(0.59) | 0 -0.036 | 8N (0.8kgf) | |||

| KM-H0015 | φ* 15(0.59) * h * 9(0.35) * 15(0.59) | 0 -0.043 | 20N (2kgf) | |||

| KM-H002 | φ* 20(0.78) * h * 9(0.35) * 15(0.59) | 0 -0.052 | 40N (4kgf) | |||

| KM-H0025 | φ * 26(1.02) * h * 9(0.35) * 25(0.98) | 0 -0.052 | 100N(10kgf) | |||

| Model | Workable Range | Upper Limit of Working Temp. | Tapping | Mass | |||

| D1 | D2 | H | H2 | ||||

| KM-0005 | 5 (0.19) | 4.5 (0.17) | _ | _ | Type B | Not allowed. | 1.5g/0.003 lb |

| KM-0007 | 7(0.27) | 6.5 (0.25) | 2.5g/0.005 lb | ||||

| KM-H001 | 10 (0.39) | 9.5 (0.37) | 15(0.59) | 12(0.47) | Type A | Prepared hole up to 3.0 deep on the rear face allowed. | 11g/0.024 lb |

| KM-H0015 | 15 (0.59) | 14 (0.55) | 20g/0.044 lb | ||||

| KM-H002 | 20 (0.78) | 18 (0.70) | 40g/0.088 lb | ||||

| KM-H0025 | 26 (1.02) | 24 (0.94) | 25(0.98) | 21(0.82) | Prepared hole up to 4.0 deep on the rear face allowed. | 100g/0.222 Ib | |

- The holding power is based on a test piece of SS400, 10 mm thick, ground surface.

- The holding power may drop when the holder is worked on additionally. In particular, additional work in the radial direction has a large influence on the holding power and therefore, must be limited to a minimum necessary scope.

Plating specification

| Model | OD x Height | Holding Power | Surface Treatment | Mounting Tapped Hole | Upper Limit of Working Temp. |

| KM-0005L | φ* 5(0.19) * 13(0.51) | 1.8N(0.18kgf) | Nickle plating | None | Type A |

| KM-0007L | φ* 7(0.27) * 13(0.51) | 4N(0.4kgf) | |||

| KM-0010H | φ* 10(0.39) * 8(0.31) | 3N(0.3kgf) | Type B | ||

| KM-001 | φ* 10(0.39) * 15(0.59) | 8N(0.8kgf) | Type A | ||

| KM-T001 | φ* 10(0.39) * 18(0.7) | M5(0.19)Depth5(0.19)pitch0.8(0.03) | |||

| KM-0015 | φ* 15(0.59) * 15(0.59) | 20N(2kgf) | None | ||

| KM-T0015 | φ* 15(0.59) * 18(0.7) | M5(0.19)Depth5(0.19)pitch0.8(0.03) | |||

| KM-0018H | φ * 18(0.7) * 8(0.31) | 50N(5kgf) | None | Type B | |

| KM-002 | φ* 20(0.78) * 15(0.59) | 40N(4kgf) | Type A | ||

| KM-T002 | φ* 20(0.78) * 18(0.7) | M5(0.19)Depth5(0.19)pitch0.8(0.03) | |||

| KM-0025H | φ* 25(0.98) * 10(0.39) | 90N(9kgf) | None | Type B | |

| KM-T0025 | φ* 26(1.02) * 30(1.18) | 100N(10kgf) | M6(0.23)Depth10(0.39)pitch1.0(0.03) | Type A | |

| KM-T003 | φ* 30(1.18) * 33(1.29) | 150N(15kgf) | M6(0.23)Depth8(0.31)pitch1.0(0.03) |

| Model | Workable Range | Tapping | Mass | |||

| D₁ | D2 | H1 | H2 | |||

| KM-0005L | _ | _ | 13 (0.51) | 12 (0.47) | Not allowed. | 2g/0.004 lb |

| KM-0007L | 7(0.27) | 6.5 (0.25) | 3.8g/0.008 lb | |||

| KM-0010H | _ | _ | _ | _ | 5g/0.011 lb | |

| KM-001 | 10(0.39) | 9.5 (0.37) | 15 (0.59) | 12 (0.47) | Prepared hole up to 3.0 deep on the rear face allowed. | 11g/0.024 lb |

| KM-T001 | 18 (0.70) | Provided. | 12g/0.026 lb | |||

| KM-0015 | 15(0.59) | 14 (0.55) | 15 (0.59) | Prepared hole up to 3.0 deep on the rear face allowed. | 20g/0.044 lb | |

| KM-T0015 | 18 (0.70) | Provided. | 23g/0.051 lb | |||

| KM-0018H | _ | _ | _ | _ | Not allowed. | 16g/0.035 lb |

| KM-002 | 20(0.78) | 18 (0.70) | 15 (0.59) | 12 (0.47) | Prepared hole up to 3.0 deep on the rear face allowed. | 40g/0.088 lb |

| KM-T002 | 18 (0.70) | Provided. | 45g/0.100 lb | |||

| KM-0025H | _ | _ | _ | _ | Not allowed. | 38g/0.083 lb |

| KM-T0025 | 26(1.02) | 24 (0.94) | 30 (1.18) | 21 (0.82) | Provided. | 120g/0.266 lb |

| KM-T003 | 30(1.18) | 27 (1.06) | 33(1.29) | 28 (1.10) | 180g/0.400 lb | |

- The holding power is based on a test piece of SS400, 10 mm thick, ground surface.

- The holding power may drop when the holder is worked on additionally. In particular, additional work in the radial direction has a large influence on the holding power and therefore, must be limited to a minimum necessary scope.

Peripheral knurling specification

| Model | OD x Height | Holding Power | Surface Treatment | Mounting Tapped Hole | Upper Limit of Working Temp. | Feature | Mass |

| KM-0010J | φ * 10(0.39) * 8(0.31) | 3N (0.3kgf) | Nickle plating | None | Type B | Peripheral knurling | 5g/0.011 lb |

| KM-0018J | φ * 18(0.7) * 8(0.31) | 50N (5kgf) | 16g/0.035 lb | ||||

| KM-0025J | φ* 25(0.98) * 10(0.39) | 90N (9kgf) | 38g/0.083 lb |

※The holding power is based on a test piece of SS400, 10 mm thick, ground surface.

Painting specification

| Model | OD x Height | Holding Power | Surface Treatment | Mounting Tapped Hole | Upper Limit of Working Temp. |

| KM-025C | φ* 26(1.02) * 25(0.98) | 100N(10kgf) | Painting | M 6(0.23), depth 8 (0.31) pitch1.0 (0.03) | Type C |

| KM-03C | φ* 30(1.18) * 25(0.98) | 150N(15kgf) | |||

| KM-04C | φ* 40(1.57) * 30(1.18) | 300N( 30kgf) | M 8(0.31), depth 12 (0.47) pitch1.25 (0.04) | ||

| KM-05C | φ * 50(1.96) * 40(1.57) | 500N(50kgf) | |||

| KM-07C | φ* 70(2.75) * 40(1.57) | 700N( 70kgf) | M12(0.47), depth 15 (0.59) pitch1.75 (0.06) | ||

| KM-08C | φ* 80(3.14) * 45(1.77) | 1000N (100kgf) | M12(0.47), depth 18 (0.70) pitch1.75 (0.06) | ||

| KM-025S | 26(1.02) * 26(1.02) * 25(0.98) | 100N(10kgf) | None | ||

| KM-06S | 26(1.02) * 60(2.36) * 25(0.98) | 200N( 20kgf) | M6 (0.23), depth 10 (0.39) pitch1.0 (0.03) |

| Model | Workable Range | Tapping | Mass | |||

| D1 | D2 | H1 | H2 | |||

| KM-025C | 26 (1.02) | 25 (0.98) | 25 (0.98) | 17 (0.66) | Provided. | 90g/0.19 lb |

| KM-03C | 30 (1.18) | 27 (1.06) | 121g/0.26 lb | |||

| KM-04C | 40 (1.57) | 36 (1.41) | 30 (1.18) | 20 (0.78) | 260g/0.57 lb | |

| KM-05C | 50 (1.96) | 46 (1.81) | 40 (1.57) | 25 (0.98) | 545g/1.20 lb | |

| KM-07C | 70 (2.75) | 60 (2.36) | 1000g/2.20 lb | |||

| KM-08C | 80 (3.14) | 66 (2.59) | 45 (1.77) | 27 (1.06) | 1600g/3.52 lb | |

| KM-025S | 26 (1.02) | 25 (0.98) | 25 (0.98) | 15 (0.59) | Prepared hole up to 11 deep on the rear face allowed. | 118g/0.26 lb |

| KM-06S | 60 (2.36) | Provided | 275g/0.60 lb | |||

※The holding power is based on a test piece of SS400, 10 mm thick, ground surface.

Kouei is Distributor/Agent of Kanetec.

Other items of Kanetec

Request the quotation for Kanetec