KITO, Lifting, TOOLS & EQUIPMENT

KITO M3 0.5t-50t Chain Block

Product made in Japan

Manufacturer: KITO

Model: M3 (CB Series)

Features

10 Important Features Of “KITO MIGHTY Model M3” Chain Hoist

- Gear Case and Hand Wheel Cover are Resistant to External Shocks

Both sides of the hoist are covered with a thick steel gear case and reinforced wheel cover. Manufactured using state-of-the-art technology, these critical components are ideally shaped and highly rigid to maintain bearing alignment and withstand external shock. - Double Enclosures Protect Against Rainwater and Dust Intrusion

The braking mechanism, comprising the heart of the hoist, is securely enclosed within the wheel and brake covers. This double coverage protects the internal mechanisms from intrusion by weather elements, mud and dust. Further, the hand chain guide attached to the wheel cover provides durability and a smooth operation of the hand chain on the hand chain wheel. - Double Pawl Spring Mechanism

Increases Safety and Reliability

The MIGHTY M3 insists on two pawl springs to deliver an extra degree of performance in case one spring is damaged. - Sure and Reliable Mechanical Brake

KITO’s dry-type asbestos-free mechanical brake ensures outstanding stopping power and safety for high performance operation. - Hooks for Easy Work

Heat-treated to withstand the rigors of the toughest jobs, the MIGHTY M3’s top and bottom hooks are ready to make your work easier. The bottom hook’s relatively large dimensions enable a load to be quickly stabilized in the proper position while the bottom yoke’s protecting guard protects the chain pin and nut from damage, further enhancing safety. - Bearing Mechanism

Increases Mechanical Efficiency

KITO’s unique ball and needle bearings optimize mechanical efficiency and produce high power output with a minimum of manual input. - Load Chain Guide Mechanism Smoothes Operation

Superior performance is designed into the MIGHTY M3. Smooth load chain movement is facilitated by having a chain guide mechanism in the flanged load sheave and guide roller. - Highly Accurate and Durable Gears

Years of research and development have enabled KITO to produce compact, highly efficient and durable gears. - Stopper Prevents Excessive Lowering

KITO’s carefully engineered stopper assembly not only prevents a load from being lowered too far, but even keeps the chain from exiting the mechanism. Increased pull force signals the operator the load has been lowered to the maximum extent. - Highly Strong Load Chain

Load chains, the component comprising the heart of the chain hoist, are made of an exclusively developed, heat treated special steel alloy. Carefully selected special steel is entirely processed at KITO’s fully automated production facilities under the most stringent quality control. Thus, all of the KITO chains are uniform in

high breaking stress of 1000N/mm2(100kgf/mm2). They have excellent quality including toughness and resistance to wear and corrosion.

Variation

Specifications

| Rated Load (W.L.L.) (t) | Code | Std.Lift (m) | Hand Chain Folded Length (m) | Chain Pull to Lift Full Load (N) [kgf] | Chain O’haulled to Lift Load One Meter (m) | Load Chain Dia.xChain Fall (mm) | Test Load (t) | Mass [Net weight] (kg) | Shipping Mass [weight] (approx.) (kg) | Mass [weight] in kg for Additional One Meter of Lift (kg) |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | CB005 | 2.5 | 2.5 | 235 [24] | 25 | 5.0×1 | 0.75 | 10 | 10.5 | 1.5 |

| 1 | CB010 | 2.5 | 2.5 | 284 [29] | 43 | 6.3×1 | 1.5 | 11.5 | 12 | 1.8 |

| 1.5 | CB015 | 2.5 | 2.5 | 343 [35] | 57 | 7.1×1 | 2.4 | 14.5 | 15 | 2.1 |

| 2 | CB020 | 3.0 | 3.0 | 353 [36] | 70 | 8.0×1 | 3 | 20 | 21 | 2.3 |

| 2.5 | CB025 | 3.0 | 3.0 | 323 [33] | 99 | 9.0×1 | 3.8 | 27 | 28 | 2.7 |

| 3 | CB030 | 3.0 | 3.0 | 353 [36] | 114 | 7.1×2 | 4.8 | 24 | 26 | 3.2 |

| 5 | CB050 | 3.0 | 3.5 | 333 [34] | 198 | 9.0×2 | 7.5 | 41 | 43 | 4.4 |

| 7.5 | CB075 | 3.5 | 4.0 | 343 [35] | 297 | 9.0×3 | 9.5 | 63 | 66 | 6.2 |

| 10 | CB100 | 3.5 | 4.0 | 353 [36] | 396 | 9.0×3 | 12.5 | 83 | 91 | 7.9 |

| 15 | CB150 | 3.5 | 4.5 | 363 [37] | 594 | 9.0×3 | 20 | 155 | 165 | 11.4 |

| 20 | CB200 | 3.5 | 4.5 | 353 [36] x2 | 396×2 | 9.0×3 | 25 | 235 | 305 | 15.8 |

| 30 | CB300 | 3.5 | 4.5 | 421 [43] x2 | 495×2 | 9.0×10 | 40 | 310 | 400 | 19.2 |

| 40 | CB400 | 3.5 | 4.5 | 421 [43] x2 | 693×2 | 9.0×14 | 50 | 480 | 630 | 26.2 |

| 50 | CB500 | 3.5 | 4.5 | 480 [49] x2 | 792×2 | 9.0×16 | 62.5 | 640 | 790 | 29.7 |

•As KITO chains are heat-treated, splicing of the load chain is prohibited.

•When ordering, specify the lifting height.

•Chain falls vary depending on the capacity of each hoist.

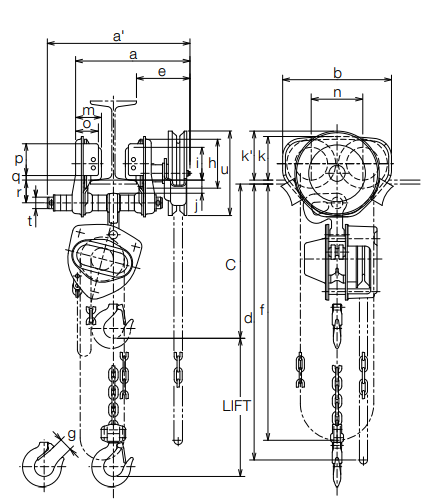

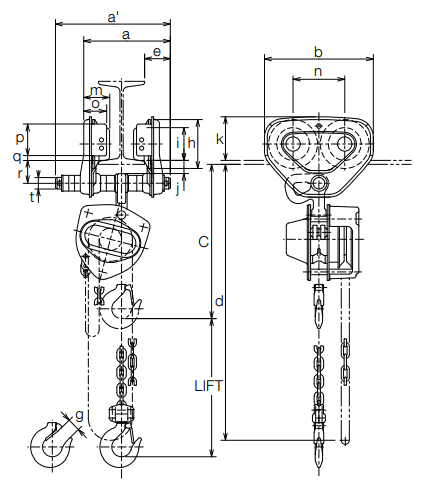

DIMENSIONS (mm)

| Rated Load (W.L.L.) (t) | Headroom :C | a | b | d | e | f | g | s | t | u | v | w | x |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 285 | 158 | 161 | 2500 | 69 | 99 | 27 | 35.5 | 12.1 | 17 | 77 | 35 | 89 |

| 1 | 295 | 162 | 161 | 2500 | 71 | 99 | 29 | 42.5 | 16 | 21.8 | 93 | 41 | 101 |

| 1.5 | 350 | 171 | 182 | 2500 | 78 | 112 | 34 | 47.5 | 19.5 | 26.5 | 106 | 47 | 119 |

| 2 | 375 | 182 | 202 | 3000 | 87 | 125 | 36 | 50 | 21.8 | 30 | 116 | 49 | 124 |

| 2.5 | 420 | 192 | 233 | 3000 | 91 | 143 | 40 | 53 | 24.3 | 33.5 | 126 | 53 | 136 |

| 3 | 510 | 171 | 235 | 3100 | 78 | 162 | 42.5 | 56 | 27.2 | 37.5 | 138 | 57 | 148 |

| 5 | 600 | 192 | 282 | 3600 | 91 | 194 | 46.5 | 63 | 34.5 | 47.5 | 161 | 67.5 | 172 |

| 7.5 | 770 | 192 | 373 | 4200 | 91 | 253 | 72.5 | 85 | 47.5 | 63 | 231 | 97.5 | 275 |

| 10 | 760 | 192 | 438 | 4200 | 111 | 308 | 72.5 | 85 | 47.5 | 63 | 231 | 97.5 | 295 |

| 15 | 1020 | 268 | 492 | 4700 | 119 | 337 | 80 | 100 | 50 | 67 | 275 | 110 | 351 |

| 20 | 1180 | 374 | 746 | 4800 | 187 | 373 | 81 | 110 | 67 | 88 | 301 | 125 | 395 |

| 30 | 1300 | 404 | 746 | 4800 | 202 | 373 | 103 | 125 | 75 | 100 | 412.5 | 143 | 445 |

| 40 | 1480 | 502 | 760 | 4900 | 251 | 380 | 96 | 145 | 123 | 155 | 467 | 182.5 | 470 |

| 50 | 1560 | 544 | 796 | 4900 | 272 | 398 | 100 | 165 | 135 | 155 | 447.5 | 202.5 | 467 |

TROLLEY-CONNECTED HOIST

GEARED TYPE

PLAIN TYPE

Specifications

| Rated Load (W.L.L.)(t) | Code | Std.Lift (m) | Hand Chain Folded Length (m) | Load Chain Dia. x Chain Fall (mm) | Test Load (t) | Mass (Net Weight) (kg) | Mass [weight] in kg for Additional One Meter of Lift (kg) |

|---|---|---|---|---|---|---|---|

| 0.5 | CBSG(CBSP)005 | 2.5 | 2.5 | 5.0×1 | 0.75 | 23(15) | 2.4(1.5) |

| 1 | CBSG(CBSP)010 | 2.5 | 2.5 | 6.3×1 | 1.5 | 24(19) | 2.7(1.8) |

| 1.5 | CBSG(CBSP)015 | 2.5 | 2.5 | 7.1×1 | 2.4 | 32(28) | 3.0(2.1) |

| 2 | CBSG(CBSP)020 | 3.0 | 3.0 | 8.0×1 | 3 | 37(33) | 3.3(2.3) |

| 2.5 | CBSG(CBSP)025 | 3.0 | 3.0 | 9.0×1 | 3.8 | 52(48) | 3.6(2.7) |

| 3 | CBSG(CBSP)030 | 3.0 | 3.0 | 7.1×1 | 4.8 | 48(44) | 4.1(3.2) |

| 5 | CBSG(CBSP)050 | 3.0 | 3.5 | 9.0×2 | 7.5 | 92(87) | 5.4(4.4) |

| 7.5 | CBSG075 | 3.5 | 4.0 | 9.0×3 | 9.5 | 175 | 7.1 |

| 10 | CBSG100 | 3.5 | 4.5 | 9.0×4 | 12.5 | 185 | 8.8 |

| 15 | CBSG150 | 3.5 | 4.5 | 9.0×6 | 20 | 395 | 13.3 |

| 20 | CBSG200 | 3.5 | 4.5 | 9.0×8 | 25 | 495 | 17.7 |

•CBSG and CBSP mean the CB Series connected with the TS Series geared trolley and plain trolley respectively.

•Figures in parentheses show the data for the plain trolley. Other data are the same for both the plain and geared trolleys.

•15 ton-and-over capacity trolleys have 8-wheel construction.

DIMENSIONS (mm)

| Rated Load (W.L.L.) (t) | Headroom :C | a (Max) | a’ | b | d | e | f | g | h | i | j | k | k’ | m | n | o | p | q | r | t | u |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 305/295 (173) | 275/251 (173) | 309/249 (204) | 236 (182) | 2500 | 116 (46) | 2300 | 27 | 106 (82) | 71 (60) | 28 (19) | 95 (76) | 106 | 56 (47.5) | 112 (84) | 50 (42) | 69 (54) | 10 | 50 (38) | 25 (22) | 183 |

| 1 | 305 | 275 (251) | 309/249 (204) | 236 (182) | 2500 | 116 (56) | 2300 | 29 | 106 | 71 | 28 | 95 | 106 | 56 | 112 (84) | 50 (42) | 69 (54) | 10 | 50 (38) | 25 (22) | 183 |