Air Preparation Equipment, Japan, KONAN ELECTRIC

KONAN VB7 Precision Type Volume Boosters

Product Made In Japan

Manufacturer: KONAN ELECTRIC

Model: VB7

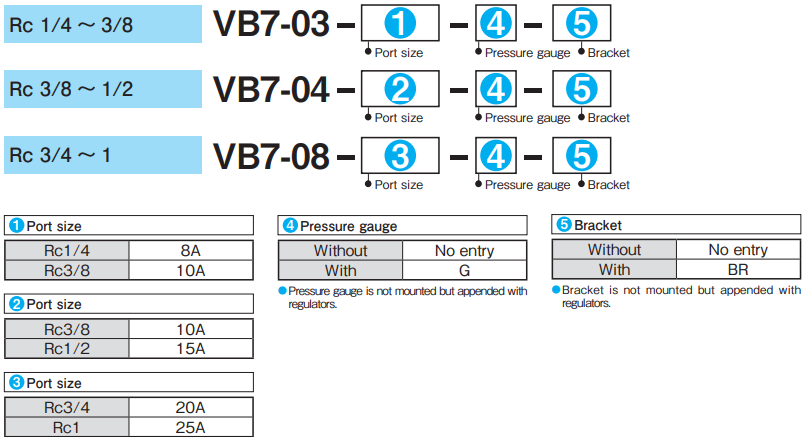

Model Code

Features

High precision

● Outstanding input/output precision assures significantly low hysteresis at pressure rise/down.

Large fluid amplification factor

● Even minimal change in signal pressure can produce a large fluid rate.

Large relief flow

● With its large relief flow volume.VB7 is suitable for tension control.

Minimal cracking pressure

● Minimal cracking pressure with a flow rate at around 0L/min allows rapid response to slight pressure change.

Slight pressure fluctuation

● Outstanding pressure characteristics minimize the effect of the primary pressure change on the secondary pressure.

By-path system

● A built-in needle valve reduces electrode hunting that may occur on the electric circuit.

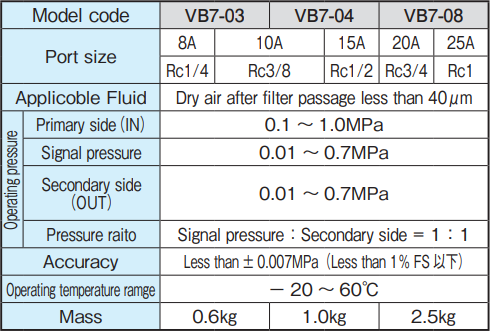

Specifications

For use below 5℃, provide adequate measures against freezing.

Make sure to produce at least 0.1MPa of the pressure difference between primary and secondary sides of the pressure port, or an appropriate flow rate cannot be achieved.

Minimal leakage may occur due to the diaphragm performance characteristics. This does not have any problem with the function.

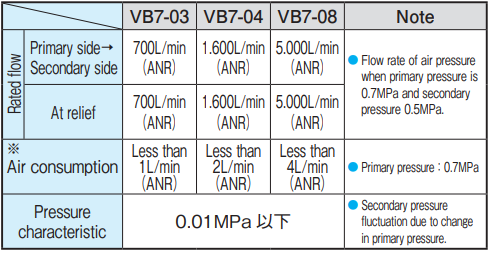

Characteristics

Operation

❶ Diaphragm“B”

Signal pressure acts on diaphragm B to open the valve.

❷ Diaphragm“A”

The secondary pressure acts on diaphragm A against signal pressure. When the secondary pressure is lower than the signal pressure, diaphragm A is forced down and the valve opens. When both pressures are equal, the valve closes. When the secondary pressure is higher than the signal pressure, the relief valve opens and releases the secondary pressure until the secondary pressure is equal to the signal pressure.

❸ Needle valve

When the needle valve is opened, the secondary side is connected to the signal pressure side. This mechanism maintains safe and stable operating conditions

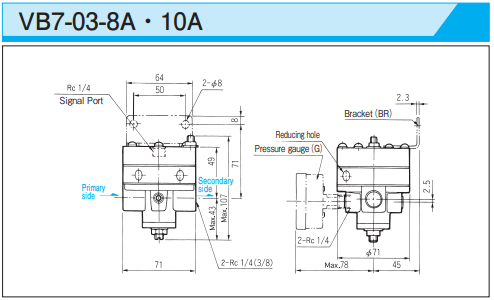

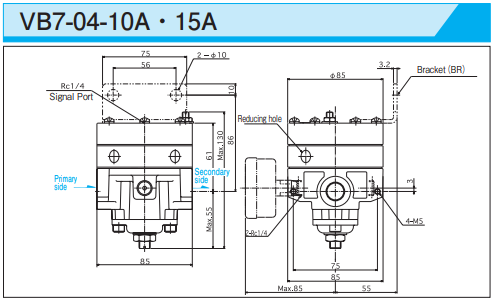

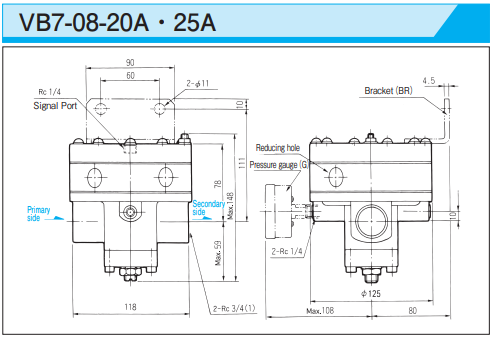

Outside Dimensions

Operating Instructions

1. Installation

Perform enough air flushing of pipes and piping materials to eliminate dust and foreign substances completely before connecting to components.

Install in the correct direction as indicated by an arrow mark on the body to make sure correct airflow.

Do NOT pressurize or close the relief port.

Place the volume booster vertically in order to minimize the effect of body weight on performance.

2. Fluid

For air supply to the primary side, filtrate the fluid using an air filter with filtration less than 40μm

3. Lubrication

Do not lubricate the volume booster.

● When lubricating downstream components using a lubricator in the open air, perform the process at the secondary side of the volume booster.

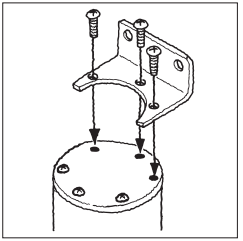

4. Bracket

Bracket is available as an option.

Remove any 3 machine screws from the top of the volume booster and mount the bracket with longer machine screws supplied with the volume booster.

5. Pressure

● Set and adjust the secondary pressure using a pilot-operated regulator.

● Set primary pressure about 0.1 MPa higher than the secondary set pressure. If there is no pressure difference, available flow volume is decreased.

- Kouei is a Distributor/Agent for KONAN.

- Other items of KONAN.

- Request the quotation for KONAN.

Related Products

-

Kokosha Fluorescent Tube Type LED Lights Ceiling Light Surface Type

-

Fujii Denko SUP-T593 (2-way RITRA) Industrial Safety Belt

-

NAGANO KEIKI KG12 P/I Converter (20 to 100kPa)

-

Ross Asia Medium series Port size is 1/4″ to 1/2″. Flow rates up to 100 scfm (2832 l/min)

-

TSUBOSAN Precsion Needle Type 5-PCS Hand Bright-900 Series

-

YOSHITAKE TF-2 Steam Trap/Air Trap