Japan, Kurimoto

Kurimoto CD- 400, CD- 500, CD- 600, CD- 800, CD- 1000 Indirect Heating Dryer

Product Made in Japan

Manufacturer: KURIMOTO

Model: CD- 400, CD- 500, CD- 600, CD- 800, CD- 1000

The CD Dryer is a low-speed agitation type of indirect heating dryer, which dries materials by heat transferred through the special hollow sectoral cut disc and casing jacket. The agitation and mixing processes by this cut disc provide large coefficient of heat transfer, enabling you to get products of stable quality

Features

Compact in size

Large heating surface area

High heat efficiency

Easy control

Even drying

Possible drying of materials of high moisture content

Minimized dead space

Less dusting

Application

The CD Dryer can process fine chemical materials including powder and particles up to submicron order in size.

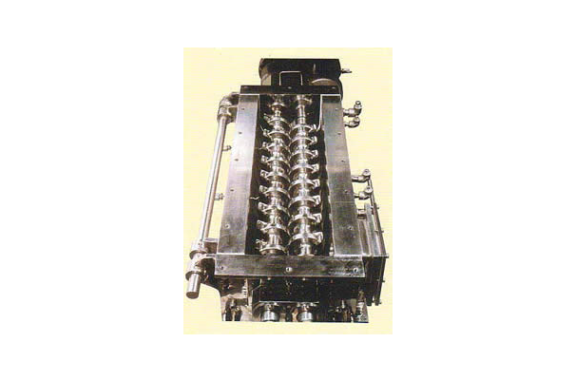

Construction

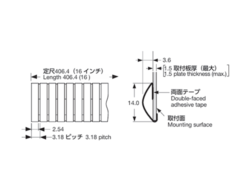

CD Dryer Construction

Disc Perspective Figure

Motion Figure of Powder and Granular Materials

Processing materials

Synthetic resins

ABS, PVC, PE, PP, Polycarbonate, and others

Food products

Malt sugar, glucose, granulated sugar, amino acid, flour, corn flour, food additives, and others

Animal feeding stuff

Various kinds of granulated products

Inorganic substance

Potassium nitrate, barium nitrate, iron sulfate, and others

Others

Sludge

Specifications

| Type | D (mm) | C (mm) | W (mm) | L (mm) | H (mm) | Heating surface area (m2) | Effective volume (L) | Rotation speed (rpm) | Power (kW) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Disc | Jacket | Total | |||||||||

| CD- 80 | 80 | 70 | 170 | 470 | 320 | 0.24 | 0.11 | 0.35 | 5 | 20<80 | 0.2 |

| CD- 160 | 160 | 120 | 300 | 1350 | 550 | 1.5 | 0.6 | 2.1 | 40 | 15<60 | 0.75<1.5 |

| CD- 250 | 250 | 190 | 480 | 2100 | 700 | 3.9 | 1.5 | 5.4 | 160 | 12<48 | 1.5<2.2 |

| CD- 300 | 300 | 230 | 570 | 2400 | 850 | 5.5 | 2.2 | 7.7 | 260 | 10<40 | 2.2<3.7 |

| CD- 400 | 400 | 300 | 740 | 2700 | 1100 | 9.2 | 3.2 | 12.4 | 510 | 8<32 | 3.7<5.5 |

| CD- 500 | 500 | 360 | 900 | 3100 | 1300 | 13.8 | 4.6 | 18.4 | 890 | 7<28 | 5.5<7.5 |

| CD- 600 | 600 | 440 | 1090 | 3400 | 1400 | 19.1 | 6.2 | 25.3 | 1420 | 5<20 | 7.5<11 |

| CD- 800 | 800 | 580 | 1430 | 4900 | 2000 | 35.2 | 12.0 | 47.2 | 3560 | 4<16 | 11<12 |

| CD-1000 | 1000 | 725 | 1775 | 5450 | 2300 | 53.0 | 16.7 | 69.7 | 5870 | 3<12 | 22<45 |