Japan, Kyowa Electronic Instruments Co., Ltd.

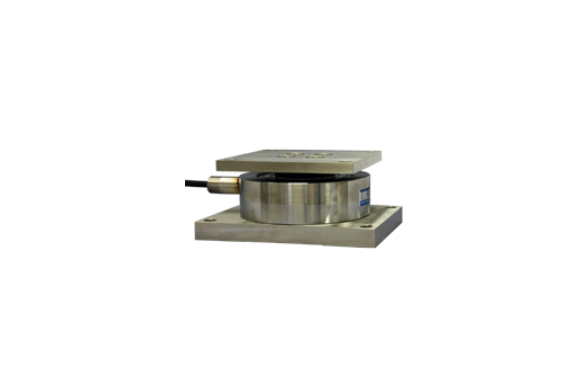

Kyowa LCTS-B-100KN LCTS-B Stainless Steel Load Cell

Made in Japan

Manufacturer: Kyowa Electronic Instruments Co., Ltd.

Model: LCTS-B-100KN

The LCTS-B is a stainless-steel load cell for measuring compressive loads of hoppers and weighing tanks. The built-in steady brace mechanism makes LCTS-B suitable for weighing stirring tanks or tank feet.

Features

• Easily install on hopper’s brackets and tank’s legs

• Hermetically-sealed structure (IP67 (IEC 60529))

• TEDS-installed versions can be manufactured.

Specifications

Performance

| Rated Capacity | 100 kN |

|---|---|

| Nonlinearity | Within ±0.05% RO |

| Hysteresis | Within ±0.05% RO |

| Repeatability | 0.02% RO or less |

| Rated Output | 2 mV/V ±0.1% |

Environmental Characteristics

| Safe Temperature | -20 to 70ºC |

|---|---|

| Compensated Temperature | -10 to 60ºC |

| Temperature Effect on Zero | Within ±0.003% RO/ºC |

| Temperature Effect on Output | Within ±0.003%/ºC |

Electrical Characteristics

| Safe Excitation | 20 V AC or DC |

|---|---|

| Recommended Excitation | 1 to 10 V AC or DC |

| Input Resistance | 700 Ω ±0.7% |

| Output Resistance | 700 Ω ±0.7% |

| Cable | 4-conductor (0.3 mm2) chloroprene shielded cable, 7.6 mm diameter by 10 m long , bared at the tip (Shield wire is not connected to the case.) |

Mechanical Properties

| Safe Overloads | 150% |

|---|---|

| Ultimate Lateral Load | 30 kN (Max. load which does not cause any mechanical damage) |

| Weight | Approx. 13 kg (Excluding calbe) |

| Materials | Stainless steel |

| Degree of Protection | IP67 (IEC 60529) |

Dimensions

To Ensure Safe Usage

(Note 1) No LCTS-B is used for any onboard measurement.

(Note 2) No LCTS-B is used in an environment where it is frequently

exposed to lateral loads.

(Note 3) No LCTS-B is installed to any inclined or vertical surfaces.

∙ Accessories to Load Cells

Do not disassemble or remodel accessories such as top plate and mounting plate designed for

installation of LCTS-B series load cells.

∙ Installation of Floating Prevention Stoppers

Install the hazard prevention stopper when using in an environment where the load cell may be

damaged or the hopper or tank may overturn due to lateral loads or lateral displacement caused by thermal expansion of structure or vibration of stirrers.