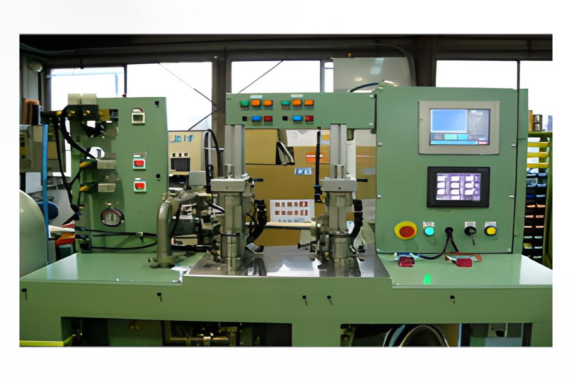

Japan, Matsuda Seiki

Matsuda Seiki Helium Leak Measuring Device

Product: Made in Japan

Manufacturer: Matsuda Seiki

Model: Helium Leak Measuring

Introducing our top-tier leak tester that utilizes helium for unparalleled accuracy—a cut above the rest! When we securely fit a workpiece into our specialized seal coupler, we can measure it swiftly, ensuring rapid and reliable results.

Proudly presenting, the “helium leak measurement device” crafted by our expertise. This device boasts an impressively low helium leak amount of 1×10^-9 Pa·m³/sec or less, setting a new standard for precision.

Regarding cycle time, our device stands out with its ability to process each piece in just 10 seconds. Moreover, it supports dual-station operations, where each station processes a piece in 20 seconds. The breakdown of the cycle includes a vacuum roughing time of 4.5 seconds, followed by a measurement time of 7.5 seconds, optimizing both efficiency and accuracy.

Beyond this state-of-the-art helium leak tester, we are also dedicated to designing and manufacturing a wide range of measuring devices and specialized machinery. Should you require equipment that meets specific needs, rest assured that we are equipped to design and produce solutions tailored to your requirements.

In conclusion, our commitment extends beyond delivering advanced equipment; we strive to provide custom solutions that cater to the unique needs of our clients, ensuring satisfaction and exceeding expectations.

Basic information

- Primary side power supply: 3-phase, 200V, 60Hz

Operation power supply: AC100V, DC24V - Air pressure on primary side: 0.5MPa or more Primary side air inlet: Plug (30PM)

Leak detector measurement pipe side roughing: Oil rotary vacuum pump supply pipe side roughing: Oil rotary vacuum pump Timing)

Mounting frame Mounting frame: steel plate + channel welded structure

Surrounding cover: steel plate Control-related operation panel: installed on the right side of the main unit

Control panel: installed on the right side of the main unit (integrated with the operation panel)

Control method: Sequencer

Equipment used: Uses our standard electrical parts