Japan, Matsuda Seiki

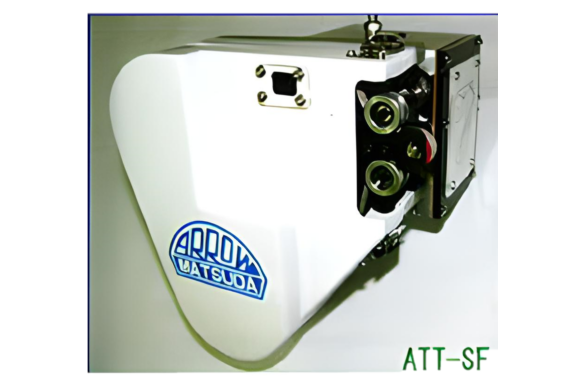

Matsuda Seiki SF Film Type Ultra-Compact Ultra-Finishing Device Attachment

Product: Made in Japan

Manufacturer: Matsuda Seiki

Model: SF Film Type Ultra-Compact Ultra-Finishing

Built into a CNC lathe as an attachment-type superfinishing device to enter the world of combined machining.

The product “Attachment SF” incorporates the superfinishing process, traditionally performed as an independent process, into a CNC lathe, enabling combined machining with superfinishing.

Compared to our existing products, the weight of the unit was 40kg, but it was downsized to 4.2kg, which is about 1/10.

As a turret built-in type with a tool rotation axis, space-saving super-finishing can improve efficiency.

Features

- Cross-hatched polishing by film oscillation mechanism

- Uniform finish with no orientation

- Drive source interlocks with lathe turret tool rotation axis

- Processing conditions can be set arbitrarily

- Film cost Minimize

Basic information

[Benefits of composite machining]

■Built into a CNC lathe for composite machining (to a turret with a tool rotation axis)

・Space saving

・Energy saving

・Shortening of machining time

・Reduction of personnel

■One chucking from cutting to super polishing

・Machining process time reduction, product precision improvement, and stable quality

Related Products

-

DIJET EZN3D Type Strike Drill

-

TSUBOSAN 10-PCS Length 160mm Precision Needle Files

-

NAC – AL TYPE 40 Brass SH (Hose nipple)

-

Chiyoda Seiki Pressure Regulator For Piping Outlet GLU-Series

-

Gentos PH-V1 Smart Phone Holder For Bike Light

-

SANKO ELECTRONIC LABORATORY HOLYSTAR-5N Pinhole And Holiday Detectors